High speed puncher interlinked precise roll-to-roll material flexible circuit board manufacturing method

A technology of flexible circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of consuming production costs, difficult to reflect fine patterns, and difficult to deform patterns, etc., to achieve low manufacturing costs, Easily achieve the effect of precision production patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] While the invention is capable of many variations and embodiments, specific embodiments will be illustrated in the drawings and the invention will be described in detail in the detailed description. However, this is not intended to limit the present invention to specific embodiments, and it should be understood that all modifications, equivalent technical solutions, and replacement technical solutions within the spirit and technical scope of the present invention are included. In the course of describing the present invention, when it is judged that the detailed description of related known technologies may obscure the gist of the present invention, the detailed description will be omitted.

[0056] Hereinafter, reel-to-reel material and material have the same meaning and will be used selectively in a contextual manner.

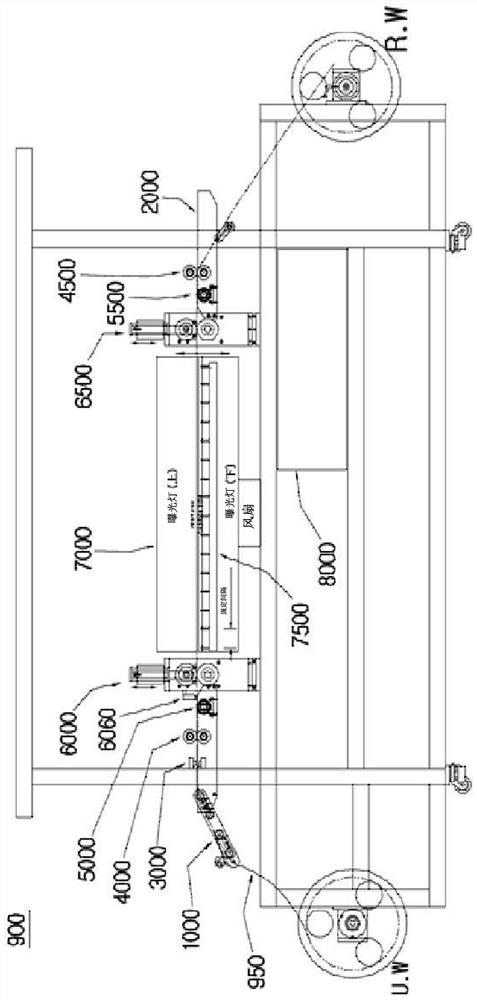

[0057] figure 2 It is a functional structural diagram of a high-speed punching machine linkage roll-to-roll material exposure system according to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com