Fluorine coating sprayed anti-corrosion cable

A fluorine-based coating technology, applied in the field of fluorine-based coating spraying anti-corrosion cables, can solve the problems of unsatisfactory cable bending effect, reduced cable service life, reduced cable anti-corrosion performance, etc., to facilitate subsequent wiring and use, prolong service life, The effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

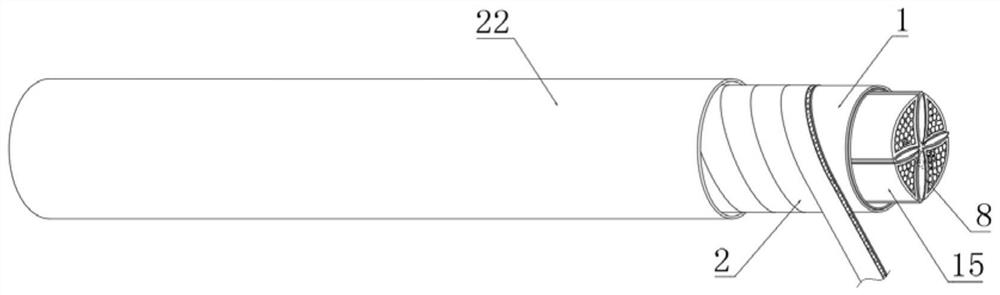

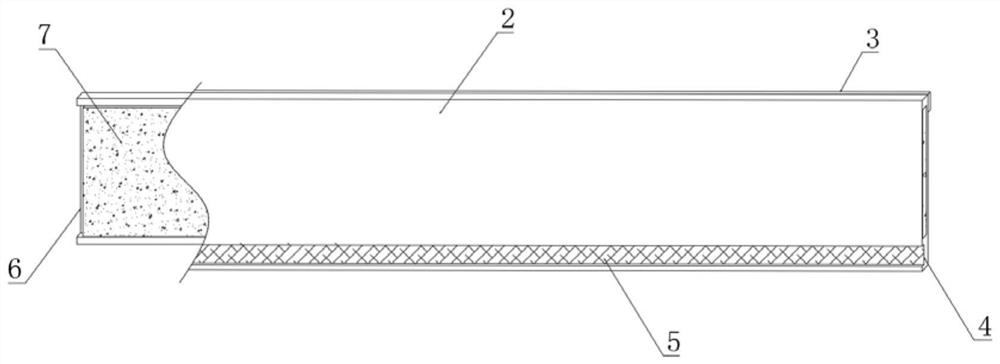

[0042] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a fluorine-based paint sprayed anti-corrosion cable, including an inner protection tube 1, a flexible belt 2 is wound on the outside of the inner protection tube 1, and a clamping strip is provided on the top back end of the flexible belt 2 3. The front end surface of the bottom of the flexible belt 2 is provided with a snap-in slot 4 that is snap-fitted with the snap-in strip 3 , and the inside of the snap-in slot 4 is bonded with a rubber strip 5 , and the width of the snap-in strip 3 is the same as the width of the snap-in slot 4 Equal, the clamping strip 3 is bonded and fixed inside the clamping groove 4 by the adhesive strip 5, so that the flexible belt 2 can be stably wound outside the inner protection tube 1, and the middle part of the flexible belt 2 is provided with a fireproof groove 6, and the inside of the fireproof groove 6 Filled with fireproof mud 7;

[0043] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com