Built-in circuit structure of CO2 fracturing device

A circuit structure and cracker technology, which is applied in the direction of weapon accessories, offensive equipment, blasting barrels, etc., can solve the problems of substandard sealing effect of bursting discs, hidden dangers of engineering construction safety, unstable circuits, etc., and solve the problem of poor internal power supply, Avoid line wear and ensure free flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

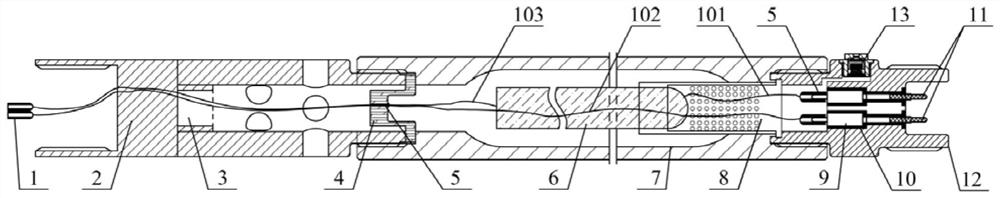

[0025] Such as figure 1 shown. CO 2 The built-in circuit structure of the cracker includes electrode socket 1, release head 2, tension type rupture disc 4, high-pressure self-tightening sealing structure 5, heater 6, liquid storage tube 7, screen tube 8, electrode 9, rubber sleeve 10, An electrode plug 11, an inflatable head 12 and an inflatable valve 13 inside the inflatable head.

[0026] The electrode 9 is wrapped with a rubber sleeve 10 and placed inside the inflatable head 12, and a high-pressure self-tightening sealing structure 5 is provided at the left end of the electrode 9;

[0027] Wherein, both ends of the inflation head 12 are provided with external threads, and the left end of the inflation head 12 is additionally provided with internal threads, and the internal threads are spirally connected with the external threads at the right end of the screen pipe 8;

[0028] The wire 101 and the wire 102 are led out from the two electrodes 9 of the inflatable head 12 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com