Method for modifying surface of polyester through combination of ultrasound and enzyme

A surface modification and ultrasonic technology, applied in the direction of enzyme/microorganism biochemical treatment, physical treatment, fiber treatment, etc., can solve the problem of poor hydrophilic modification effect of polyester fiber enzymatic method, shorten the reaction time and increase the release amount. , the release effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

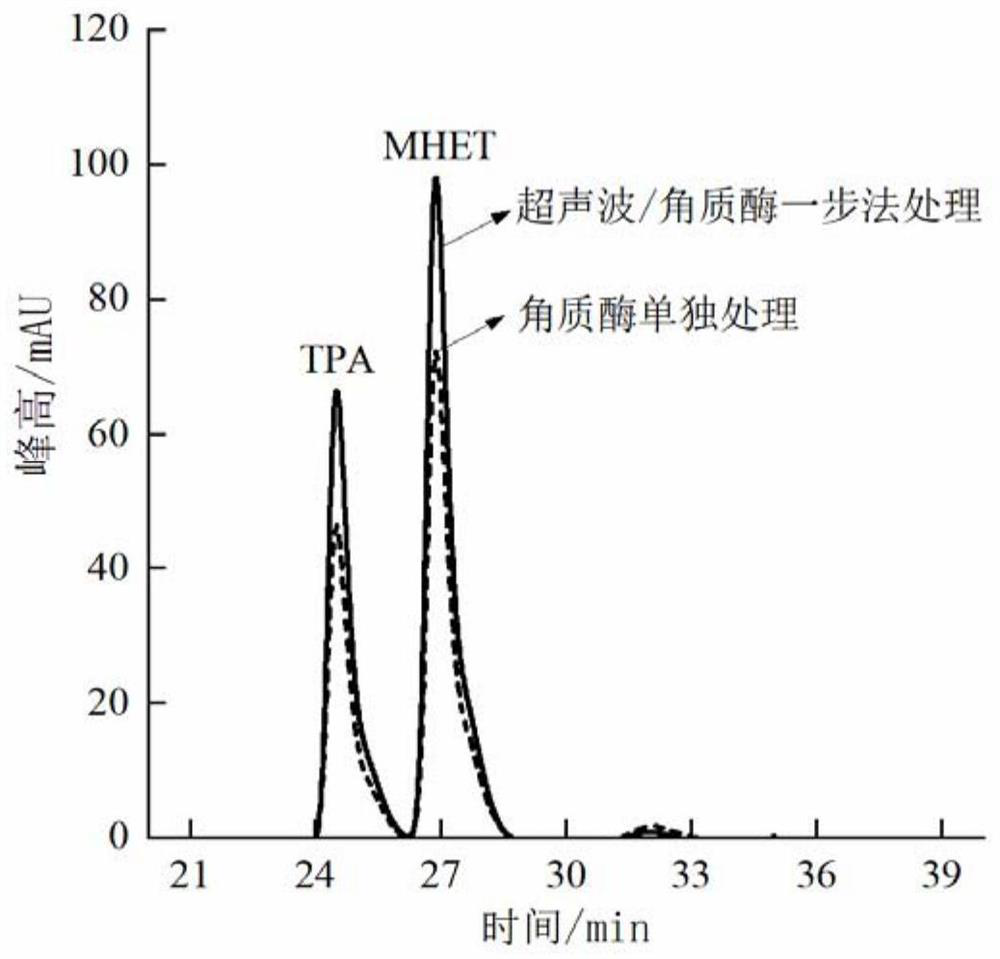

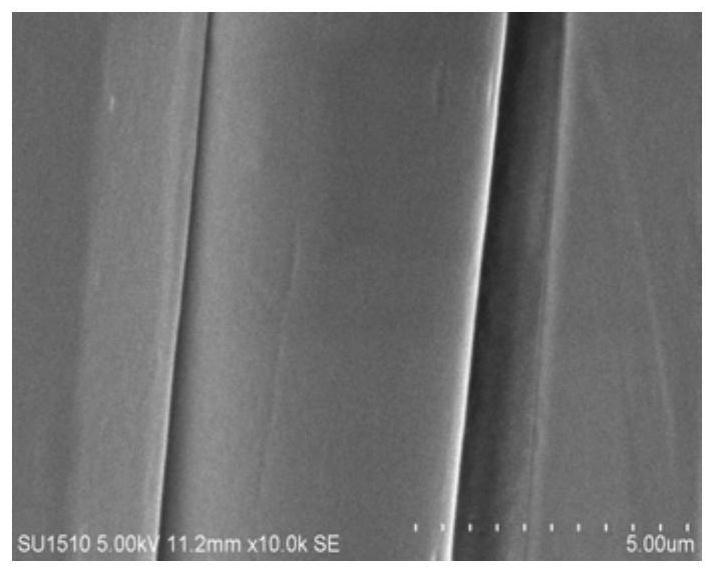

[0069] Embodiment 1-Ultrasonic combined cutinase one-step treatment polyester fabric

[0070] A method for modifying the surface of polyester by ultrasonic combined with enzyme, comprising the steps of:

[0071] (1) Ultrasound combined with enzyme treatment: place the refined polyester fabric (0.4g) in Humicola insolens cutinase solution (Tris-HCl buffer solution with a pH of 8.0 5mmol / L and a concentration of 100U / mL with an activity of 800-900U / mL of Humicola insolens cutinase), the bath ratio is 1:40, the reaction system is sealed with a parafilm, and treated with an ultrasonic water bath cleaner for 2 hours, and the ultrasonic temperature of the water bath is controlled at 60°C;

[0072] (2) Shaking table treatment: transfer the reaction system obtained in step (1) to a shaking table (60° C., 150 rpm) to continue the reaction for 24 hours, and take out the polyester fabric after the reaction;

[0073] (3) Post-treatment: The polyester fabric obtained in step (2) was firs...

Embodiment 2

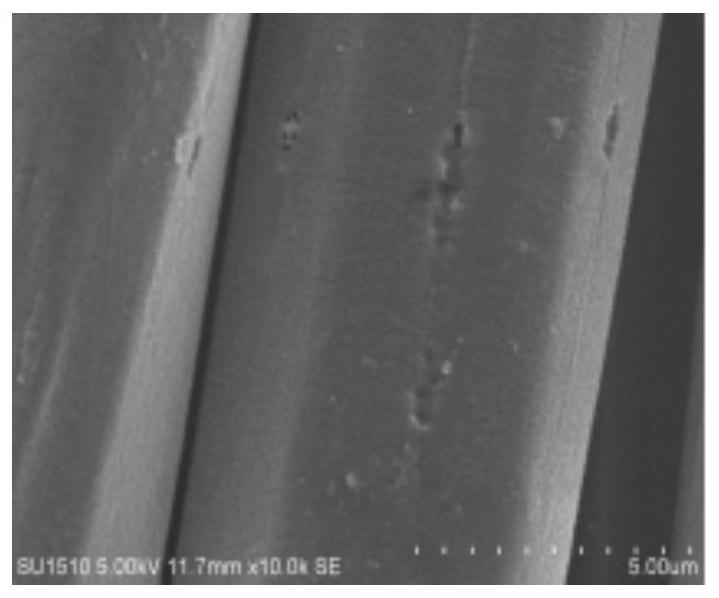

[0089] Embodiment 2 Ultrasound+Cutinase, Ultrasonic Treatment, Cutinase Treatment Comparative Research

Embodiment 2-1

[0090] Example 2-1: A method for modifying the surface of polyester with ultrasound combined with enzymes. Referring to Example 1, the only difference is that (2) the shaker treatment step is omitted, and the polyester fabric obtained in step (1) is directly subjected to the step (3) After-treatment, sample 4 was prepared: polyester filament fabric treated with ultrasound+cutinase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com