Photothermal conversion multifunctional fabric and preparation method thereof

A light-to-heat conversion, multi-functional technology, applied in the direction of plant fibers, light-resistant fibers, textiles and papermaking, etc., can solve the problem of poor air permeability, hand feeling and washing resistance of recycled fabrics, which are difficult to use on a large scale. The problem of low thermal conversion efficiency, etc., achieves the effects of excellent anti-ultraviolet function, adjustable photothermal conversion efficiency, and excellent photothermal conversion function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Using DMF as a solvent, the mass fraction of PU is 6%, and the mass fraction of ZrC is 4%. Put PU into DMF solvent, heat and stir to make DMF-PU solution.

[0024] 2) Take out the DMF-PU solution, add the previously weighed ZrC and electromagnetically stir it evenly.

[0025] 3) After the stirring is completed, put it into an ultrasonic oscillator and treat it at room temperature for a period of time to make a DMF-PU-ZrC suspension.

[0026] 4) Set the parameters of the GA391 single yarn sizing machine, as shown in Table 1, put the DMF-PU-ZrC suspension as a slurry in the size tank, and pass the cotton yarn (20S / 2) through the DMF-PU-ZrC in sequence The suspension was dried in an oven to obtain a cotton / 4%ZrC / 6%PU composite yarn.

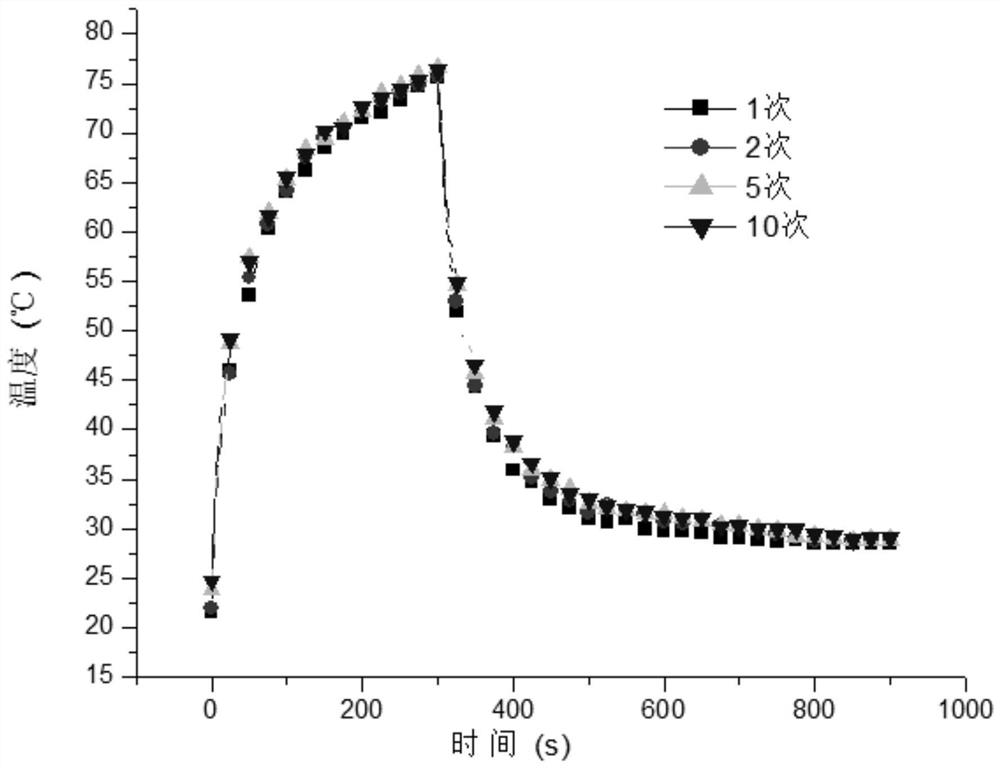

[0027] 5) The cotton / 4%ZrC / 6%PU composite yarn is woven on a flat knitting machine to obtain a cotton / polyurethane / zirconium carbide composite knitted fabric. The specific knitted fabric parameters are: double rib weave, horizontal densi...

Embodiment 2

[0032] 1) DMF is used as solvent, the mass fraction of PU is 5%, and the mass fraction of ZrC is 4%. Put PU into DMF solvent, heat and stir to make DMF-PU solution.

[0033] 2) Take out the DMF-PU solution, add the previously weighed ZrC and electromagnetically stir it evenly.

[0034] 3) After the stirring is completed, put it into an ultrasonic oscillator and treat it at room temperature for a period of time to make a DMF-PU-ZrC suspension.

[0035] 4) Set the parameters of the GA391 single yarn sizing machine, as shown in Table 2, put the DMF-PU-ZrC suspension as a slurry into the size tank, and pass the polyester yarn (20S / 2) through the DMF-PU in sequence -ZrC suspension, and then obtained polyester / 4%ZrC / 5%PU composite yarn after oven drying.

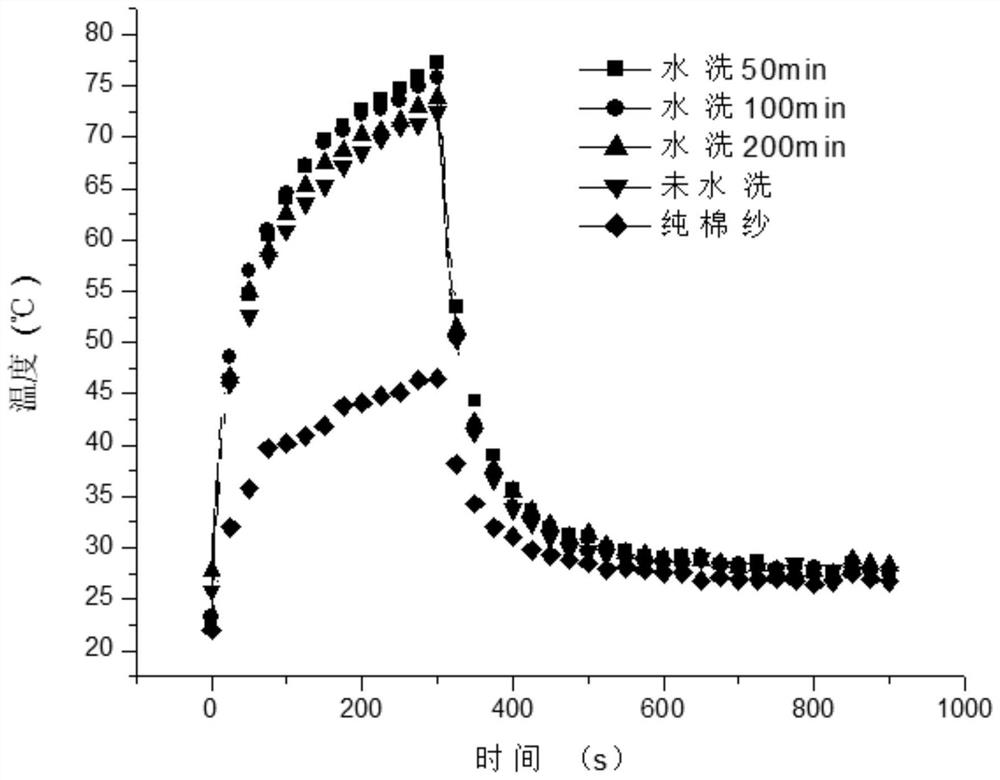

[0036] 5) Weaving the polyester / zirconium carbide / polyurethane composite yarn obtained above through a small prototype weaving machine to obtain a polyester / zirconium carbide / polyurethane composite fabric. The specific fabric p...

Embodiment 3

[0041] 1) Using DMF as a solvent, the mass fraction of PU is 8%, and the mass fraction of ZrC is 6%. Put PU into DMF solvent, heat and stir to make DMF-PU solution.

[0042] 2) Take out the DMF-PU solution, add the previously weighed ZrC and stir it electromagnetically for 1 h.

[0043] 3) After the stirring is completed, put it into an ultrasonic oscillator and treat it at room temperature for a period of time to make a DMF-PU-ZrC suspension.

[0044] 4) Set the parameters of the GA391 single yarn sizing machine, as shown in Table 3, put the DMF-PU-ZrC suspension as a slurry into the size tank, and pass the polyester yarn (30tex) through the DMF-PU-ZrC in sequence The suspension was dried in an oven to obtain a polyester / 6%ZrC / 8%PU composite yarn.

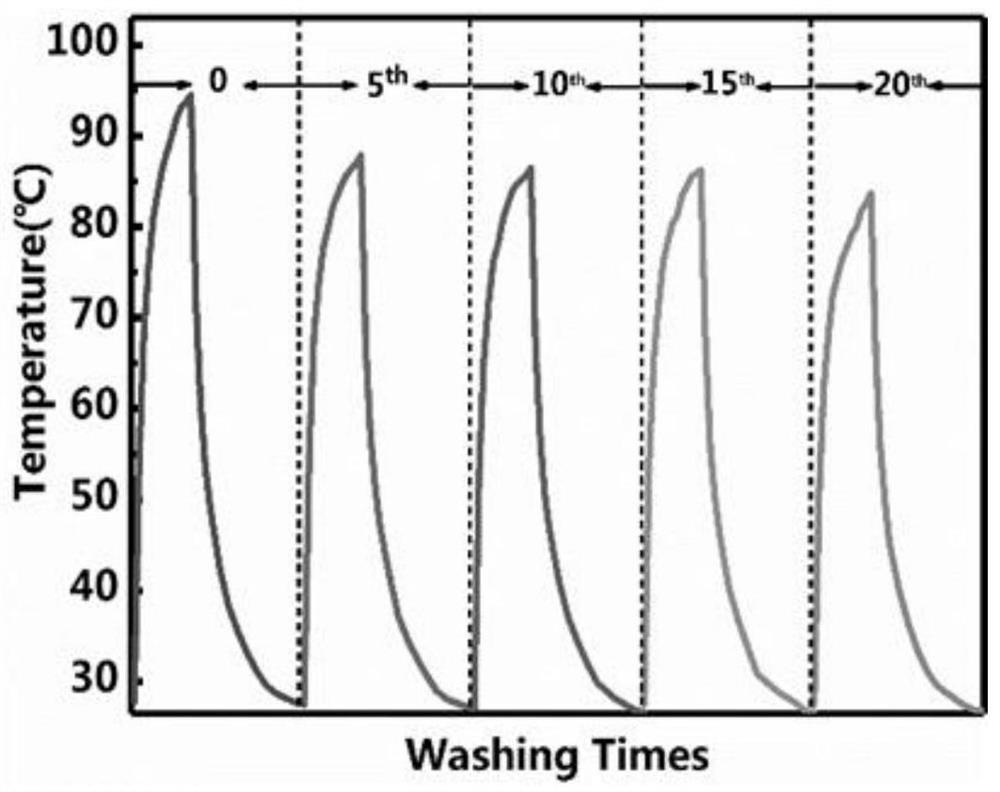

[0045] 5) Weaving the polyester / zirconium carbide / polyurethane composite yarn obtained above by a flat knitting machine to obtain a polyester / zirconium carbide / polyurethane composite knitted fabric. The specific fabric paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com