Preparation method of membrane material for solar interface evaporation seawater desalination

A technology of solar energy and membrane materials, applied in the field of solar desalination, can solve the problems of poor mechanical properties and low light-to-heat conversion efficiency, achieve ideal corrosion resistance, improve light-to-heat conversion efficiency, and increase evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

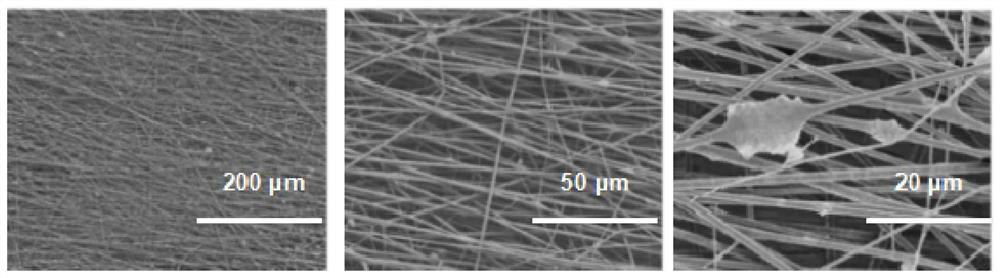

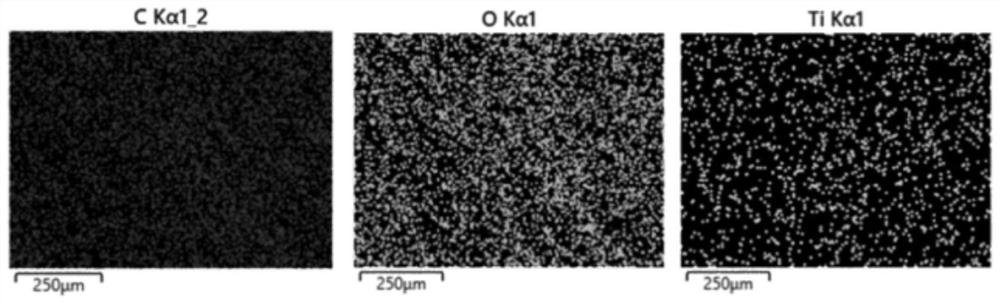

Image

Examples

Embodiment 1

[0027] A method for preparing a film material for desalination of seawater by evaporation of solar energy interface, comprising:

[0028] (1) Ti 3 C 2 T x The preparation method of (MXene) nano sheet comprises:

[0029] At room temperature, in a 100mL polytetrafluoroethylene beaker, dissolve 2g of lithium fluoride in 40mL of hydrochloric acid (the concentration of hydrochloric acid is 9mol / L), stir and mix thoroughly for 40min; then, slowly add 2g of Ti 3 AlC 2 powder, after the feeding is completed, the reaction solution is placed at 35°C and continuously stirred for 24 hours; after the reaction, the reaction solution is centrifuged 8 times at a speed of 7000rpm, and the lower layer of sediment is removed, and washed with distilled water until the pH of the solution is neutral , and then dried in a vacuum oven at 60°C for 24 hours to obtain Ti 3 C 2 T x (MXene) nanosheets;

[0030] (2) The preparation method of PLA-g-HPC comprises:

[0031] Under nitrogen atmosphere,...

Embodiment 2

[0041] A method for preparing a film material for desalination of seawater by evaporation of solar energy interface, comprising:

[0042] At room temperature, in a 100mL polytetrafluoroethylene beaker, dissolve 2g of lithium fluoride in 40mL of hydrochloric acid (the concentration of hydrochloric acid is 9mol / L), stir and mix thoroughly for 60min; then, slowly add 2g of Ti 3 AlC 2 powder, after the addition is complete, place the reaction solution at 35°C and continuously stir for 24 hours; after the reaction, centrifuge the reaction solution at a speed of 8000rpm for 5 times, remove the lower layer of sediment, and wash it with distilled water until the pH of the solution is neutral , and then dried in a vacuum oven at 60°C for 24 hours to obtain Ti 3 C 2 T x (MXene) nanosheets;

[0043] (2) The preparation method of PLA-g-HPC comprises:

[0044] Under nitrogen atmosphere, add 14.5g L-lactide and 0.7g hydroxypropyl cellulose to 100mL toluene respectively, then raise the ...

Embodiment 3

[0048] A method for preparing a film material for desalination of seawater by evaporation of solar energy interface, comprising:

[0049] At room temperature, in a 100mL polytetrafluoroethylene beaker, dissolve 2g of lithium fluoride in 40mL of hydrochloric acid (the concentration of hydrochloric acid is 9mol / L), stir and mix thoroughly for 50min; then, slowly add 2g of Ti 3 AlC 2 powder, after the feeding is completed, the reaction solution is placed at 35°C and continuously stirred for 24 hours; after the reaction, the reaction solution is centrifuged 6 times at a speed of 7500rpm, and the lower layer of precipitate is removed, and washed with distilled water until the pH of the solution is neutral , and then dried in a vacuum oven at 60°C for 24 hours to obtain Ti 3 C 2 T x (MXene) nanosheets;

[0050] (2) The preparation method of PLA-g-HPC comprises:

[0051] Under nitrogen atmosphere, add 14.5g L-lactide and 0.7g hydroxypropyl cellulose to 100mL toluene respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com