Treatment-free environment-friendly coating for printing plate and preparation method of treatment-free environment-friendly coating

A printing plate, treatment-free technology, applied in the field of printing plates, can solve problems such as affecting the performance of use and easily causing microbial enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of modified additives:

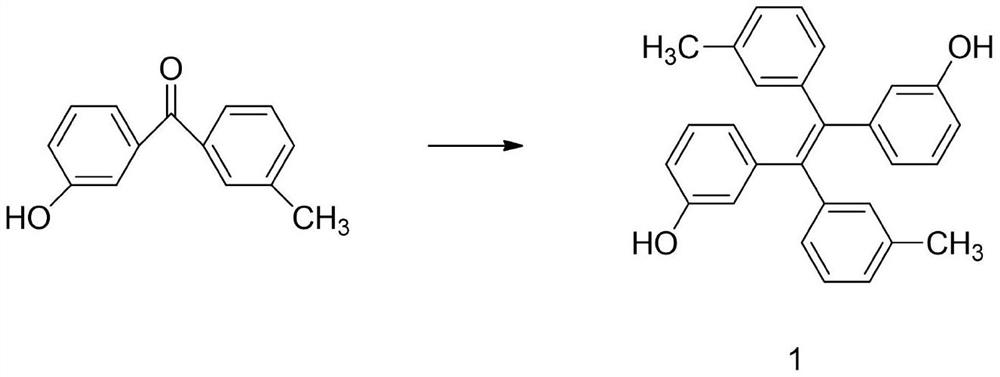

[0052] Step S11: Add 4-hydroxy-4'-methylbenzophenone and zinc powder into the flask, then add tetrahydrofuran, blow in nitrogen, and drop tetrahydrofuran into the flask under the condition of temperature -30°C and speed of 100r / min. Titanium chloride, after the dropwise addition, stir at room temperature for 1 hour, then heat up to 90°C for reflux reaction for 10 hours, and then perform post-treatment. The post-treatment steps are: cooling, suction filtration, rotary evaporation, and adding a hydrochloric acid solution with a mass fraction of 10%. , and then add toluene for extraction, after drying with anhydrous sodium sulfate, rotary evaporation and recrystallization, the intermediate 1 is obtained;

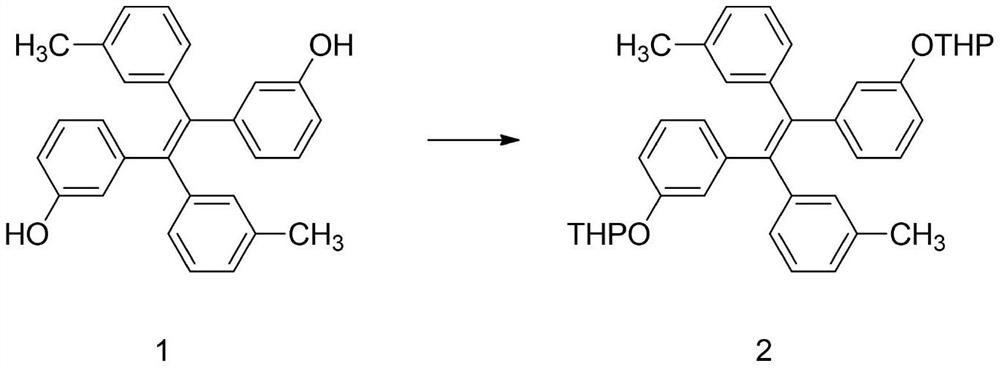

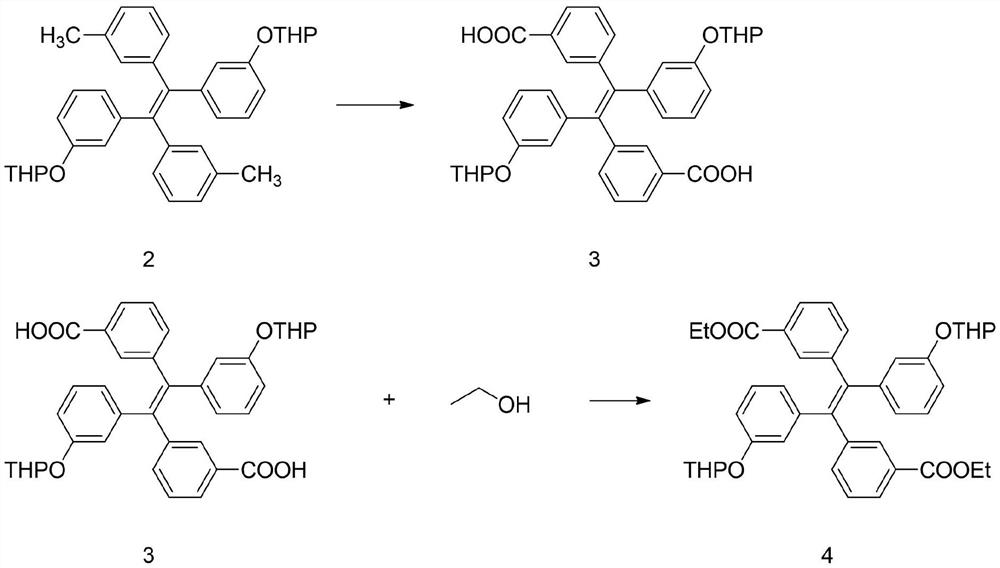

[0053] Step S12: Add intermediate 1 and dichloromethane to the flask, stir at room temperature for 10 min, then add 3,4-dihydropyran and pyridine p-toluenesulfonate into the flask at a temperature of 22°C, and stir at 22°C 1h, and th...

Embodiment 2

[0060] Preparation of modified additives:

[0061] Step S11: Add 4-hydroxy-4'-methylbenzophenone and zinc powder into the flask, then add tetrahydrofuran, blow in nitrogen, and drop tetrahydrofuran into the flask under the condition of temperature -30°C and speed of 100r / min. Titanium chloride, after the dropwise addition, stir at room temperature for 2 hours, then heat up to 90°C for reflux reaction for 10 hours, and then perform post-treatment. The post-treatment steps are: cooling, suction filtration, rotary evaporation, and then adding a hydrochloric acid solution with a mass fraction of 10%. , and then add toluene for extraction, after drying with anhydrous sodium sulfate, rotary evaporation and recrystallization, the intermediate 1 is obtained;

[0062] Step S12: Add intermediate 1 and dichloromethane to the flask, stir at room temperature for 10 min, then add 3,4-dihydropyran and pyridine p-toluenesulfonate into the flask at a temperature of 22°C, and stir at 24°C 1h, ...

Embodiment 3

[0069] Preparation of modified gelatin

[0070] Described modified gelatin is made by following steps:

[0071] Step S1: Add gelatin and phosphate buffer solution with a pH of 10 into the beaker, stir for 3 minutes, swell at room temperature for 40 minutes, then stir for 1 hour at a temperature of 55°C and a speed of 200 r / min, and obtain a gelatin solution after stirring;

[0072] Step S2: Add the gelatin solution into the flask, then add the modification aid prepared in Example 1, stir and react for 6 hours at a temperature of 50°C and a rotation speed of 300r / min, and perform post-treatment after the reaction. The post-processing step is: Freeze-dried at -45°C for 12 hours, then washed three times with methanol at 40°C, and washed three times with deionized water, and then freeze-dried at -60°C for 10 hours to obtain modified gelatin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com