Composition and application of low-temperature and hydration synergistic low-heat early-strength cement slurry system

A technology with low hydration heat and cement slurry, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high hydration heat release, long waiting time, low early strength, etc., and achieve filtration loss Less, shorter waiting time, adjustable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

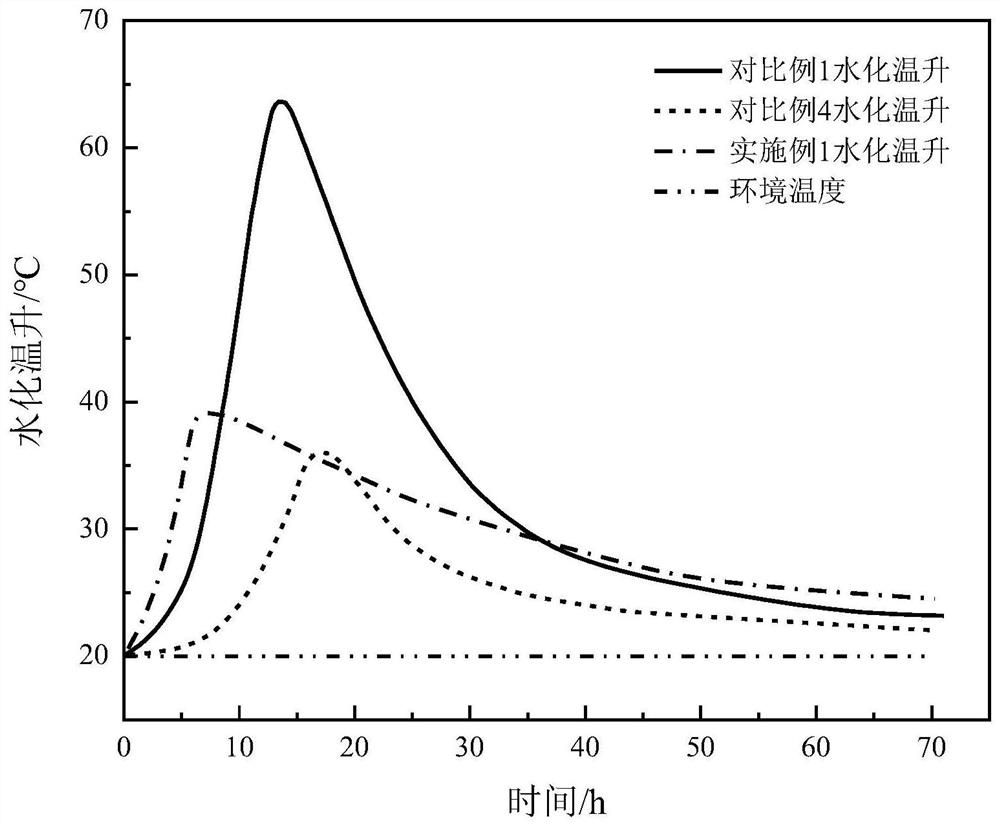

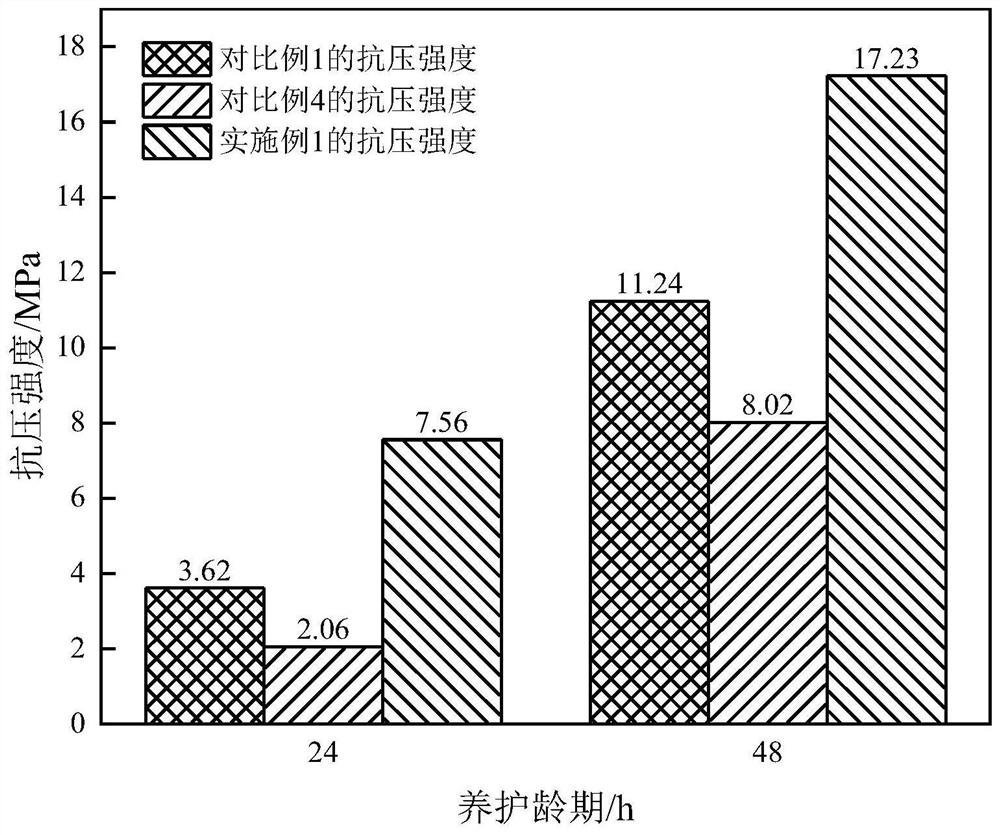

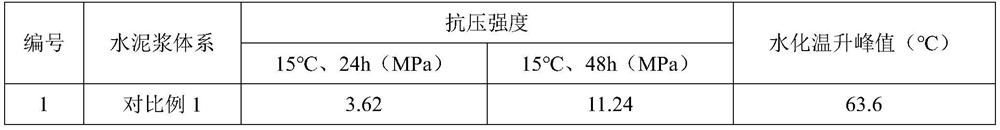

Embodiment 1

[0049] The low-heat early-strength cement slurry system of this embodiment with synergistic hydration and synergistic effect is prepared from the following raw material components in parts by mass: 100 parts of G-grade oil well cement, 100 parts of low-hydration thermally active cementitious material, hydration Calcium silicate-polycarboxylate nanocomposite early strength agent 5.8 parts, low temperature activator 4.5 parts, fluid loss reducer 0.9 parts, dispersant 0.3 parts, defoamer 0.2 parts, hollow glass microspheres 16 parts, water 81 parts , slurry density 1.45g / cm 3 .

[0050] The low-hydration thermally active gelling material comprises the following components in parts by weight: 43 parts of fly ash, 36 parts of slag, 9 parts of superfine expanded perlite, and 12 parts of solid nano silicon dioxide.

[0051] The preparation method of the low-heat early-strength cement slurry system with synergistic hydration and synergistic effect at low temperature comprises the fol...

Embodiment 2

[0054] The low-heat early-strength cement slurry system of this embodiment with low-temperature synergistic hydration enhancement is prepared from the following raw material components in parts by mass: 100 parts of G-grade oil well cement, 70 parts of low-hydration thermally active cementitious material, hydration Calcium silicate-polycarboxylate nanocomposite early strength agent 3.6 parts, low temperature activator 2.8 parts, fluid loss reducer 0.7 parts, dispersant 0.5 parts, defoamer 0.4 parts, hollow glass microspheres 18 parts, water 70 parts , slurry density 1.52g / cm 3 .

[0055] The low-hydration thermally active gelling material comprises the following components in parts by weight: 43 parts of fly ash, 36 parts of slag, 9 parts of superfine expanded perlite, and 12 parts of solid nano silicon dioxide.

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] The low-heat early-strength cement slurry system of this embodiment with synergistic hydration and synergistic effect is prepared from the following raw material components in parts by mass: 100 parts of G-grade oil well cement, 100 parts of low-hydration thermally active cementitious material, hydration Calcium silicate-polycarboxylate nanocomposite early strength agent 4.3 parts, low temperature activator 5.4 parts, fluid loss reducer 1.2 parts, dispersant 0.4 parts, defoamer 0.3 parts, hollow glass microspheres 16 parts, water 85 parts , slurry density 1.43g / cm 3 .

[0059] The low-hydration thermally active gelling material comprises the following components in parts by weight: 43 parts of fly ash, 36 parts of slag, 9 parts of superfine expanded perlite, and 12 parts of solid nano silicon dioxide.

[0060]The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com