Cement clinker, cement composition, and manufacturing method of cement clinker

A cement clinker and quality technology, applied in cement production, solid waste management, sustainable waste treatment, etc., can solve the problems of high heat of hydration, limited usage, increase of A amount, etc., and achieve the effect of low heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

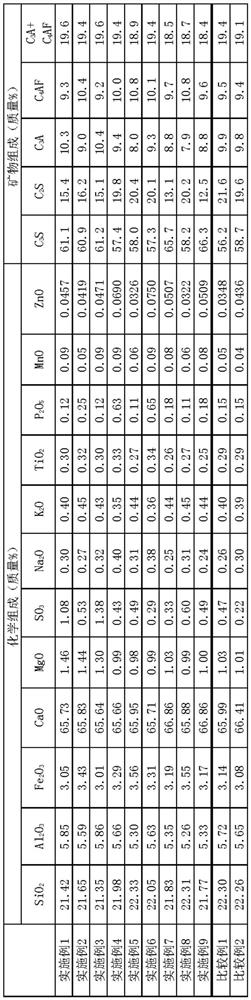

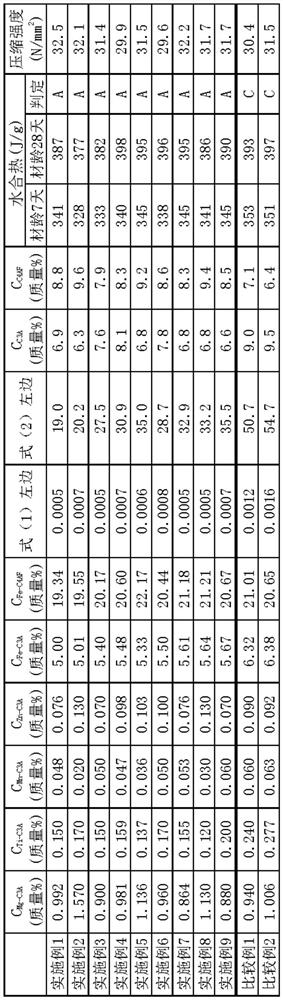

[0110] Hereinafter, the present invention will be described in more detail with reference to Examples. However, the present invention is not limited in any way by the following examples.

[0111] 1. Measurement and evaluation

[0112] 1-1. Clinker composition

[0113] The chemical composition (content ratio of each component) in the cement clinker of Examples and Comparative Examples is based on JIS R5204:2019 "Fluorescent X-ray Analysis Method for Cement" and JCAS I-53:2018 "Quantitative Method for Trace Components in Cement" Determination. Mineral composition depends on the obtained CaO, SiO 2 , Al 2 O 3 and Fe 2 O 3 The mass ratio of , was calculated using the following Bogue formula. The results are shown in Table 1.

[0114] C 3 S=(4.07×CaO)-(7.60×SiO 2 )-(6.72×Al 2 O 3 )-(1.43×Fe 2 O 3 )

[0115] C 2 S=(2.87×SiO 2 )-(0.754×C 3 S)

[0116] C 3 A=(2.65×Al 2 O 3 )-(1.69×Fe 2 O 3 )

[0117] C 4 AF=3.04×Fe 2 O 3

[0118] In addition, the value on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com