Method for curing arsenic by using red mud/metakaolin-based multi-component solid waste geopolymer

A technology of metakaolin and geopolymer, applied in the field of heavy metal pollution control and solid waste treatment, can solve the problems of high treatment cost, poor stability, formation of sludge, etc., achieve reduction and harmless disposal, reduce diffusion and harm , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

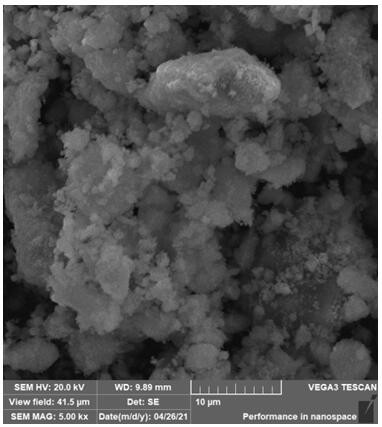

Image

Examples

Embodiment 1

[0023] Example 1: This example is taken from a smelter in Yunnan. The main components are shown in Table 1; the height is from a smelter in Henan. The main components are shown in Table 2; blast furnace slag from a smelter in southwest, mainly The ingredients are shown in Table 3; toxic sand comes from a mining area in Jiangxi, the main components are shown in Table 4;

[0024] Table 1 Red mud component

[0025] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

AS 2 O 3

15 16 21 13 5 0.4 10 0.01

[0026] Table 2 Gaolin ingredient

[0027] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

0.4 44.45 43.2 2.37 0.2 2.3 0.05 0.2

[0028] Table 3 blast furnace slag ingredients

[0029] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

42 27 13 0.3 1 8 0.4 0.3

[0030] Table 4 toxic sand ingredients

[0031] Cao SiO 2

Al 2 O 3

FE 2 O...

Embodiment 2

[0044] Example 2: This example is taken from a smelter in Yunnan. The main components are shown in Table 1; the height is from a smelter in Henan. The main components are shown in Table 2; the blast furnace slag from a smelter in the southwest, mainly The ingredients are shown in Table 3; toxic sand comes from a mining area in Jiangxi, the main components are shown in Table 4;

[0045] Table 1 Red mud component

[0046] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

AS 2 O 3

14.2 12 23 11 4 2.3 9.6 0.02

[0047] Table 2 Gaolin ingredient

[0048] Cao SiO2 Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

0.3 41.45 44.2 2.57 0.4 3.3 0.45 0.3

[0049] Table 3 blast furnace slag ingredients

[0050] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

42.3 27.2 13.2 0.27 1.0 5.7 0.2 0.8

[0051] Table 4 toxic sand ingredients

[0052] Cao SiO 2

A...

Embodiment 3

[0066] Example 3: This example is taken from a smelter in Yunnan, and the main components are shown in Table 1; the genolin comes from a smelter in Henan. The main components are shown in Table 2; blast furnace slag from a smelter in the southwest, mainly The ingredients are shown in Table 3; toxic sand comes from a mining area in Jiangxi, the main components are shown in Table 4;

[0067] Table 1 Red mud component

[0068] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

AS 2 O 3

11.2 7 23 13 3 1.3 8.5 0.03

[0069] Table 2 Gaolin ingredient

[0070] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

0.1 44.45 41.2 2.57 0.4 3.3 0.45 0.3

[0071] Table 3 blast furnace slag ingredients

[0072] Cao SiO 2

Al 2 O 3

FE 2 O 3

TiO 2

MGO NA 2 O

K 2 O

45.3 22.2 10.2 1.27 1.0 3.7 0.2 0.8

[0073] Table 4 toxic sand ingredients

[0074] Cao SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com