Construction method for machining special-shaped steel component through positioning frame

A construction method and positioning frame technology, applied in metal processing machinery parts, positioning devices, metal processing, etc., can solve the problems of difficult positioning, large angle deviation, and low precision, so as to reduce engineering costs, save labor costs, and speed up construction The effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

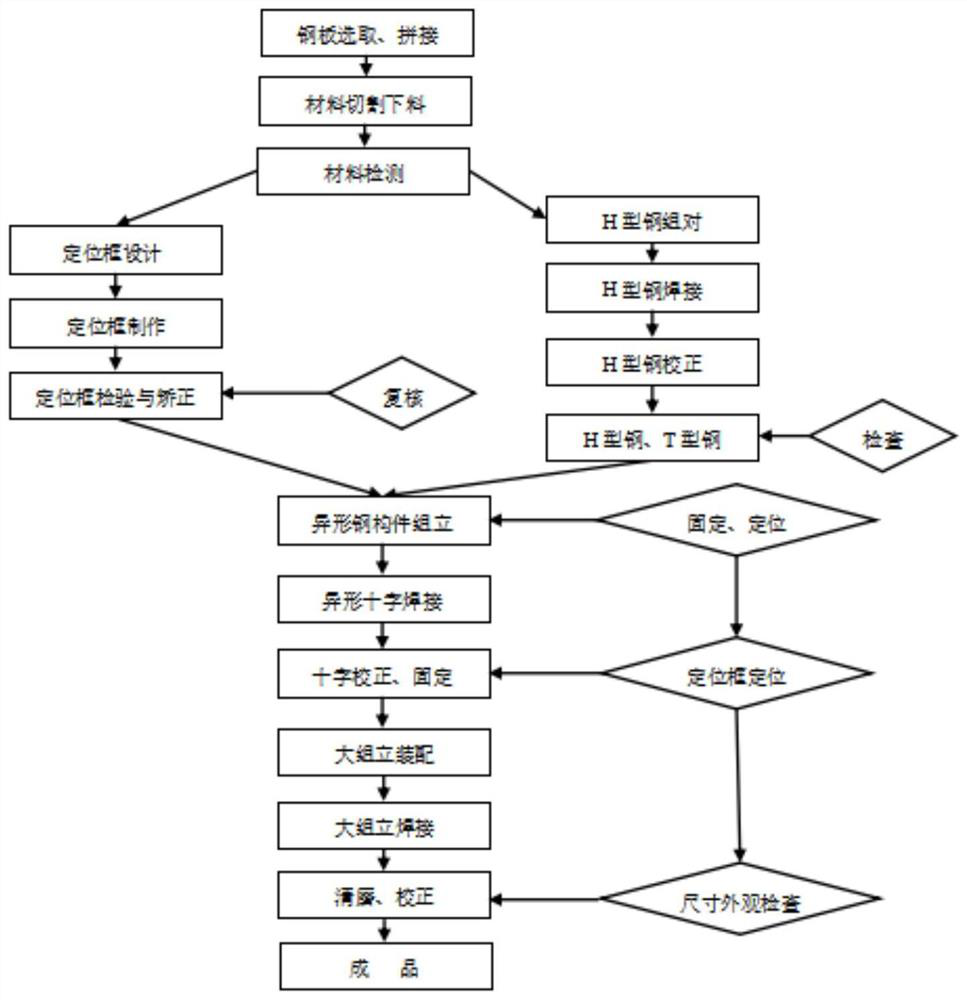

[0028] see figure 1 , a construction method for processing special-shaped steel members using a positioning frame, comprising the following steps:

[0029] Step 1. Steel plate splicing. The operator should mark the steel plate according to the requirements of the splicing diagram, then cut and splice the steel plate, and polish the splicing joint groove surface and the range of 20mm on both sides of the groove. No oil, rust and other dirt;

[0030] Step 2. Cutting and blanking of the main material. Use a straight strip cutting machine to vertically blank both sides of the wing plate and web of the section steel member at the same time, and check the first piece. After the blanking is completed, the construction personnel should transplant the furnace batch number according to the material , mark the project name, steel plate specification, and part number on the parts after blanking, and store them in categories;

[0031] Step 3. Assembling the H-shaped steel, use a semi-aut...

Embodiment 2

[0048] see figure 1 , a construction method for processing special-shaped steel members using a positioning frame, comprising the following steps:

[0049] Step 1. Steel plate splicing. The operator should mark the steel plate according to the requirements of the splicing diagram, then cut and splice the steel plate, and polish the splicing joint groove surface and the range of 20mm on both sides of the groove. No oil, rust and other dirt;

[0050] Step 2. Cutting and blanking of the main material. Use a straight strip cutting machine to vertically blank both sides of the wing plate and web of the section steel member at the same time, and check the first piece. After the blanking is completed, the construction personnel should transplant the furnace batch number according to the material , mark the project name, steel plate specification, and part number on the parts after blanking, and store them in categories;

[0051] Step 3. Assembling the H-shaped steel, use a semi-aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com