High-precision welding stainless steel wire rubbing and polishing device

A technology for wiping powder and moisturizing stainless steel wire, applied in the field of stainless steel wire, can solve the problems of inability to wipe the powder completely, affecting the welding of stainless steel wire, etc., and achieve the effect of easy storage and subsequent welding, easy popularization and use, and novel and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

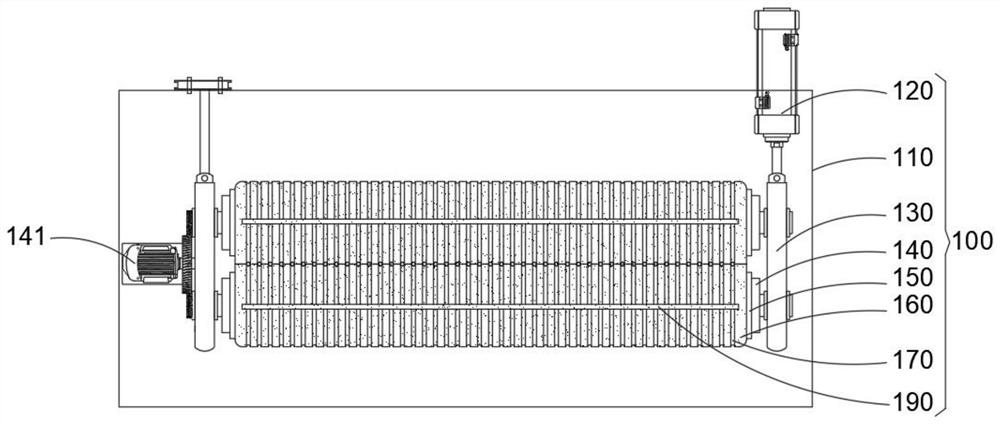

[0042] combine Figure 1-8 As shown, the high-precision welding stainless steel wire wiping and running device for high-precision welding provided by the present invention includes: a powder wiping mechanism 100, a material receiving mechanism 200 and a wire running mechanism 300, and the powder wiping mechanism 100 includes a box body 110 for stainless steel wire to pass through , two sets of elevators 120 installed on the box body 110, installation plates 130 hinged on the moving ends of the elevators 120, two sets of rollers 140 installed between the installation plates 130, transmission belts 150 sleeved on the rollers 140, connected to The powder wiping pad 160 used to wipe the stainless steel wire on the transmission belt 150, the powder wiping tank 170 set on the powder wiping pad 160 for limiting the stainless steel wire, and the powder wiping tank 170 installed in the powder wiping tank 170 to scratch the powder The powder block 180 and the blanking chute 190 located ...

Embodiment 2

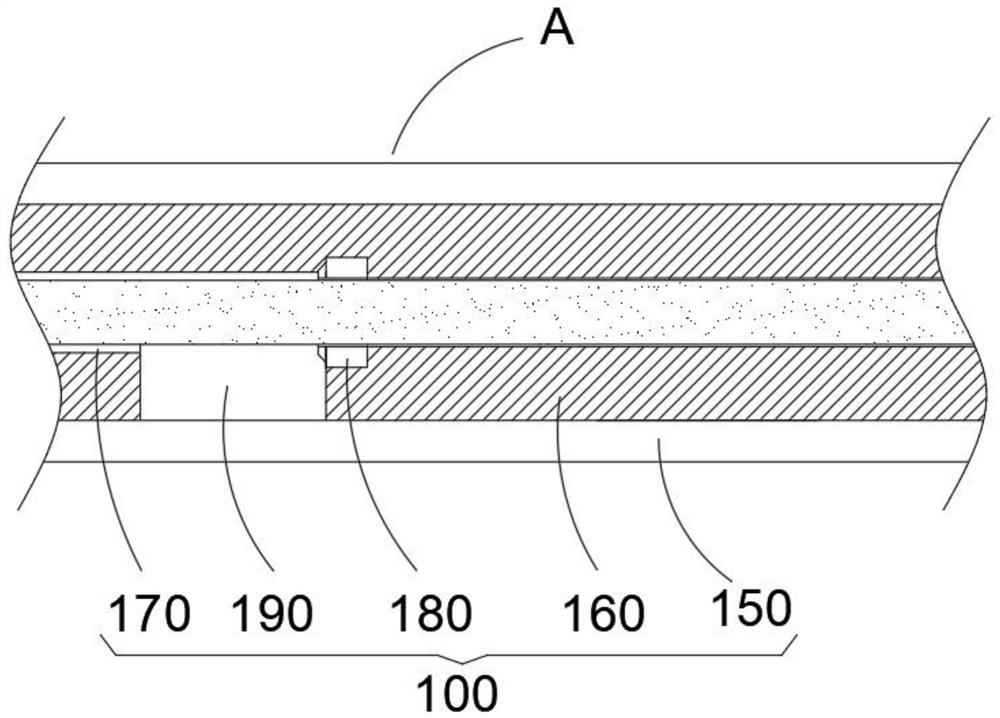

[0047] combine Figure 5-6 As shown, on the basis of Embodiment 1, the powder wiping block 180 includes a limiting block 181 installed on the powder wiping pad 160 and connected with the powder wiping groove 170, and a wiper set at the feeding end of the limiting block 181 for cleaning powder. The vermicelli 182, is connected to the fixed side 183 that bolts are fixed on the side of the limit block 181, and the powder rubbing effect can be further improved on the powder rubbing groove 170 by the rubbing powder block 180, which has a better effect on some powders that adhere more firmly. The role of the stop block 181 mainly plays the role of shaping, so that the inside of the powder wiping bar 182 is connected with the inside of the powder wiping groove 170, which is conducive to improving the powder wiping effect, and the chalk wiping bar 182 can be made of fine steel ball material, which can The powder on the surface of the stainless steel wire is scraped off, and the cleani...

Embodiment 3

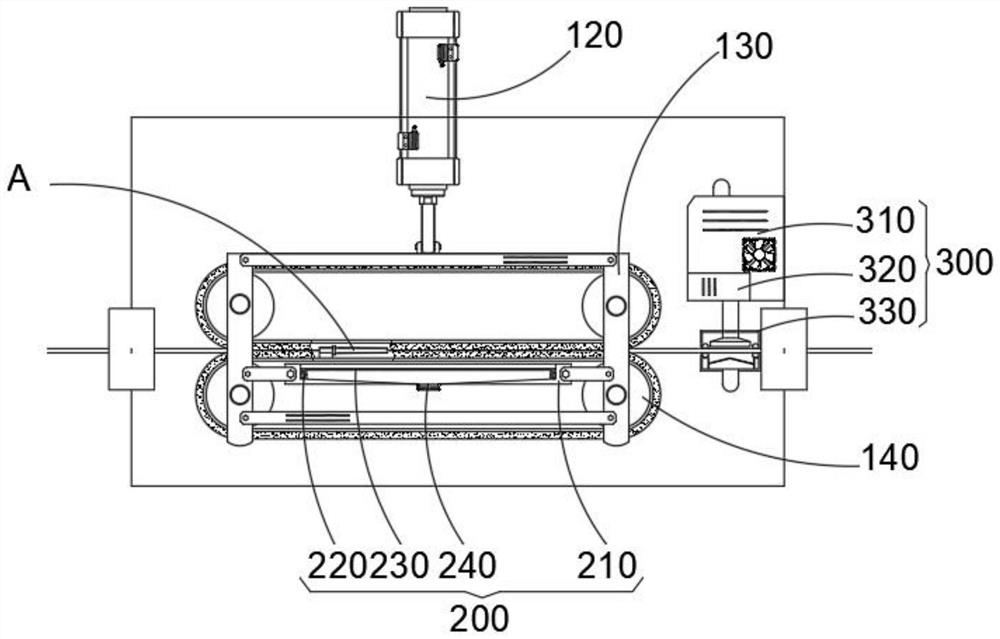

[0051] combine Figure 3-4 As shown, in the above-mentioned embodiment, the thread-running mechanism 300, the thread-running mechanism 300 is arranged on the output end side of the powder wiping mechanism 100, and is used for secondary cleaning of the stainless steel wire. The stainless steel wire is blown clean under high pressure to prevent the remaining powder on the powder wiping mechanism 100 from adhering to the stainless steel wire. After the process, the final dusting is carried out, and after the stainless steel wire is discharged from the thread running mechanism 300, it contacts the lubricating oil in the filter cotton cylinder 350, Complete lubrication of stainless steel wire for storage and subsequent welding.

[0052] Specifically, the thread running mechanism 300 includes an air purifier 310 installed on the box body 110, a booster pump 320 connected to the air purifier 310 for pressurizing and exhausting, a box body 330 arranged at the rear end of the powder wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com