Electric wire and cable powder coating device

A powder coating, wire and cable technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems that powder cannot be completely absorbed, talcum powder loses fluidity, and core wires stick to core wires. To achieve the effect of eliminating internal agglomeration, good fluidity and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

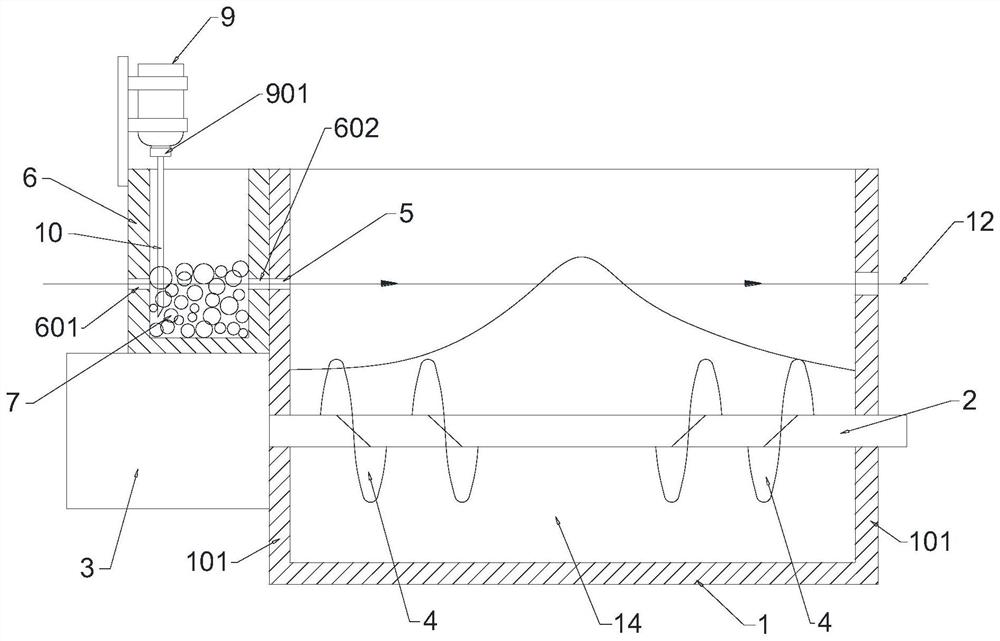

[0024] like figure 1 The above-mentioned powder coating device for electric wires and cables includes a powder box 1, and a rotary shaft 2 is horizontally arranged in the powder box 1. One end of the powder box 1 protrudes out of the powder box 1 through the end plate 101 and is connected with the drive motor 3 in a driving manner. The rotating shaft 2 located in the powder box 1 is fixedly sleeved with two spiral blades 4 with opposite directions of rotation. 2 are arranged in sequence in the axial direction, and the end plates 101 at both ends of the powder box 1 are respectively provided with coaxially arranged wire-passing holes 5 .

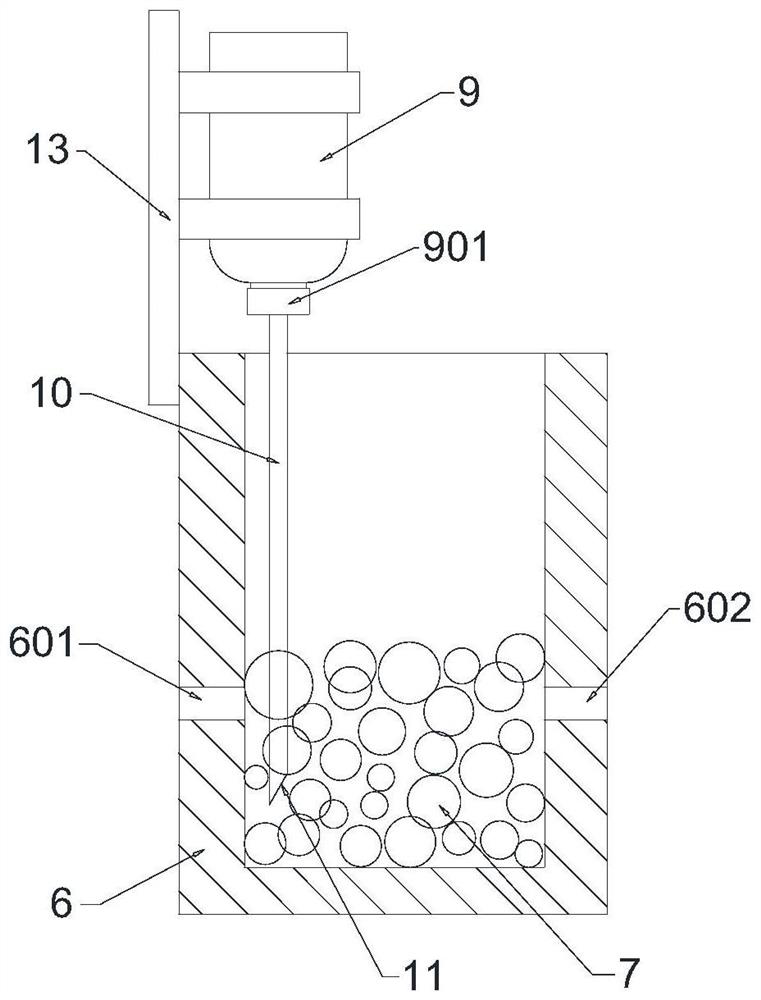

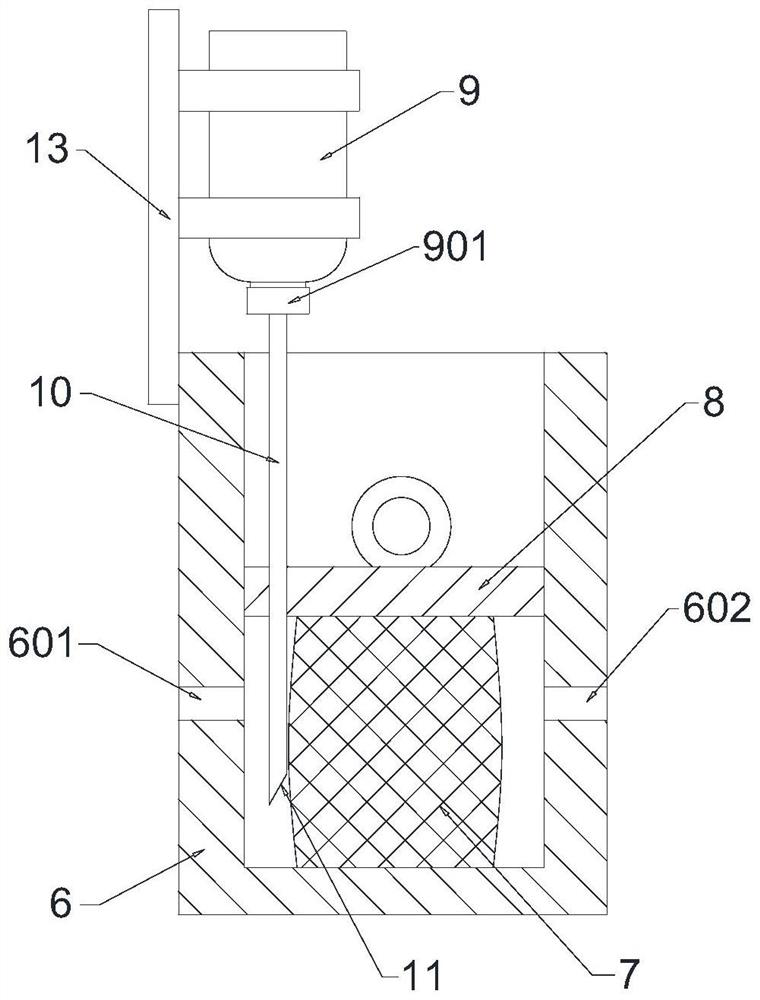

[0025] An infiltration box 6 is connected to the outer wall of the upstream end plate 101 of the powder box 1. The infiltration box 6 is provided with an infiltration liquid carrier 7. The upstream and downstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com