Powder coating device for electric wire and cable

A wire and cable, powder coating technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as missing coating and affecting the quality of wires and cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

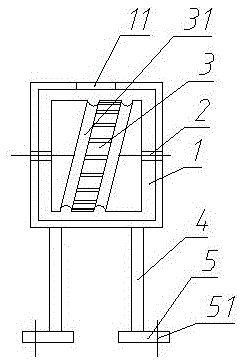

[0012] Below in conjunction with accompanying drawing, a kind of powder coating device of electric wire and cable of the present invention is further described:

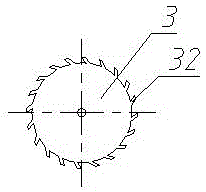

[0013] Depend on figure 1 and figure 2 It can be seen that the present invention includes a material box 1, a support shaft 2 and a powder coating wheel 3, the support shaft 2 is arranged in the material box 1, and the powder coating wheel 3 is provided on the support shaft 2, and the powder coating wheel 3 is arranged on the described support shaft 2. The cylindrical surface of the powder wheel 3 is provided with spiral grooves 31, and several powder shoveling boards 32 are arranged between adjacent spiral grooves 31; two support rods 4 are provided below the feed box 1, and the support A foot 5 is provided at the lower end of the rod 4 , and a screw hole 51 is provided on the foot 5 .

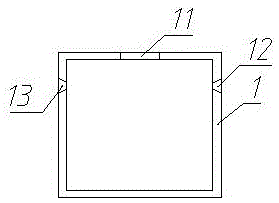

[0014] Depend on image 3 It can be seen that the top of the material box 1 is provided with a feeding port 11 , and the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com