High-creep-resistance ultra-high molecular weight polyethylene fiber and preparation method thereof

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber treatment, fiber chemical characteristics, etc., can solve the problems of chemical structure inhomogeneity, fiber surface crosslinking, poor performance, etc. Achieve the effect of enhancing antioxidant performance, reducing oxidation phenomenon, and overcoming time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

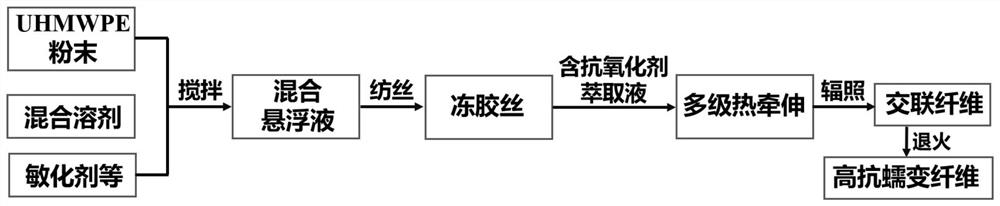

[0034] see figure 1 Shown, the invention provides a kind of preparation method of high creep resistance ultra-high molecular weight polyethylene fiber, comprises the steps:

[0035] S1, preparation of mixed suspension: mix ultra-high molecular weight polyethylene powder, mixed solvent, antioxidant and sensitizer according to a predetermined ratio, and stir for 8-20 hours to achieve sufficient swelling and uniform dispersion to obtain a uniform mixed suspension;

[0036] S2, spinning extraction: the mixed suspension obtained in step S1 is placed in a twin-screw extruder for spinning treatment, and then passed through a cooling water bath to obtain primary jelly filaments; the primary jelly filaments are passed through an extractant and an anti- The mixed extract composed of oxidant is extracted and then dried, and then the primary fiber product is obtained through multi-stage hot drawing and multi-stage oven;

[0037] S3, radiation cross-linking: the initial fiber product is s...

Embodiment 1

[0048] Embodiment 1 of the present invention provides a method for preparing a high-creep-resistant ultra-high molecular weight polyethylene fiber, comprising the following steps:

[0049] S1, preparation of mixed suspension: mix ultra-high molecular weight polyethylene powder, mixed solvent, antioxidant and sensitizer at a ratio of 10; 87; 2; 1, and stir for 12 hours to achieve full swelling and uniform dispersion, and keep mixing The dynamics of the liquid are uniform and consistent, and a uniform mixed suspension is obtained;

[0050] Wherein, the mixed solvent is a mixed solution of paraffin oil and white oil; the sensitizer is trimethylolpropane trimethacrylate; and the antioxidant is tert-butyl hydroquinone.

[0051] S2, spinning extraction: the mixed suspension obtained in step S1 is passed through a twin-screw extruder, a spinneret and a spinning box (3-6 times pre-drawing), and after spinning, it is obtained through a cooling water bath primary jelly silk; the primar...

Embodiment 2-5

[0063] The difference from Example 1 is: the ratio of antioxidant in the suspension in step S1, and the ratio of extractant and antioxidant in the extraction process of step S2 are set differently, as shown in Table 1.

[0064] Table 1 is the process parameter setting of embodiment 1-5 and the performance parameter of monofilament fiber

[0065]

[0066] Combined with Table 1 for analysis:

[0067] The effect of the proportion of antioxidants in the suspension on the creep elongation or oxidation resistance of high-creep-resistant ultra-high molecular weight polyethylene fibers is: the proportion of antioxidants in the suspension affects the oxidation during fiber spinning degree. Within a certain range, the higher the proportion of antioxidants, the smaller the degree of oxidation. The degree of oxidation determines the chemical structure of the fiber. Severe oxidation will increase the creep elongation of the fiber.

[0068] In the mixed extract, the effect of the ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com