Method for directly preparing aviation gasoline and aviation kerosene from polyolefin waste plastics

A technology of aviation gasoline and aviation kerosene, which is applied in the preparation of liquid hydrocarbon mixtures, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of harsh reaction conditions, waste plastic pollution, environmental pollution, etc., and achieve carbon cycle, consumption Low and high yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1Rh / Nb 2 o 5 Catalyst preparation

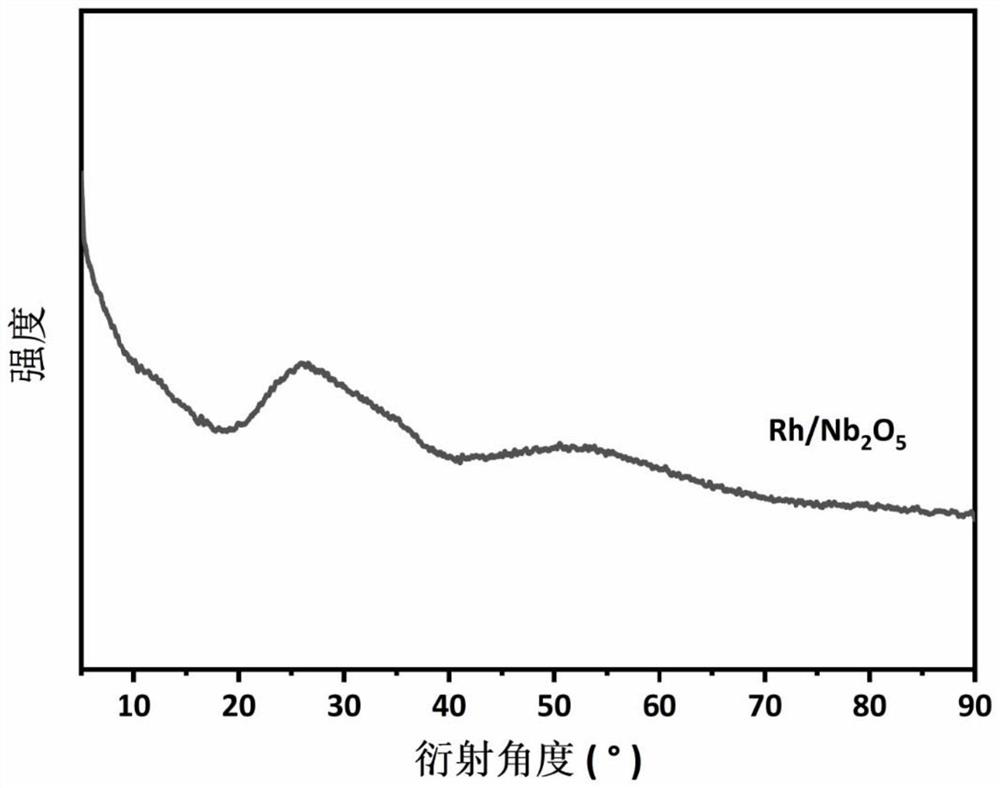

[0019] Measure 2.63mL of RhCl 3 . 3H 2 O (3g / 100mL) solution was added to a 100mL round bottom flask, and then 1g of carrier (Nb 2 o 5 ) and 60 mL of deionized water, and stirred at room temperature for 12 hours. After the impregnation, the water was removed by rotary evaporation, and dried at 80 ° C for 12 hours to ensure that the water was completely removed. Subsequently, the prepared catalysts were calcined at 400°C for 3h in a mixed atmosphere of oxygen and argon (1:1), the theoretical metal loading of all catalysts was 3wt.%. ℃ pre-reduced for 2h, its X-ray diffraction pattern is as follows figure 1 .

Embodiment 2

[0020] Example 2Rh / Al 2 o 3 Catalyst preparation

[0021] Measure 2.63mL of RhCl 3 . 3H 2 O (3g / 100ml) solution was added into a 100ml round bottom flask, and then 1g of carrier (Al 2 o 3 ) and 60ml of deionized water, and stirred at room temperature for 12 hours. After the impregnation, the water was removed by rotary evaporation, and dried at 80°C for 12 hours to ensure that the water was completely removed. Subsequently, the prepared catalyst was calcined at 400°C for 3h in a mixed atmosphere of oxygen and argon (1:1), and the theoretical metal loading of the obtained catalyst was 3wt.%. Before each reaction, the catalyst was heated in a tube furnace under hydrogen Pre-reduction at 300°C for 2h under atmosphere.

Embodiment 3

[0022] Example 3Rh / ZrO 2 Catalyst preparation

[0023] Measure 2.63mL of RhCl 3 . 3H 2 O (3g / 100ml) solution was added to a 100ml round bottom flask, and then 1g carrier (ZrO 2 ) and 60ml of deionized water, and stirred at room temperature for 12 hours. After the impregnation, the water was removed by rotary evaporation, and dried at 80°C for 12 hours to ensure that the water was completely removed. Subsequently, the prepared catalysts were calcined at 400°C for 3 h in a mixed atmosphere of oxygen and argon (1:1), and the theoretical metal loading of all catalysts was 3 wt.%. Before each reaction, the catalysts were heated in a tube furnace under hydrogen Pre-reduction at 300°C for 2h under atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com