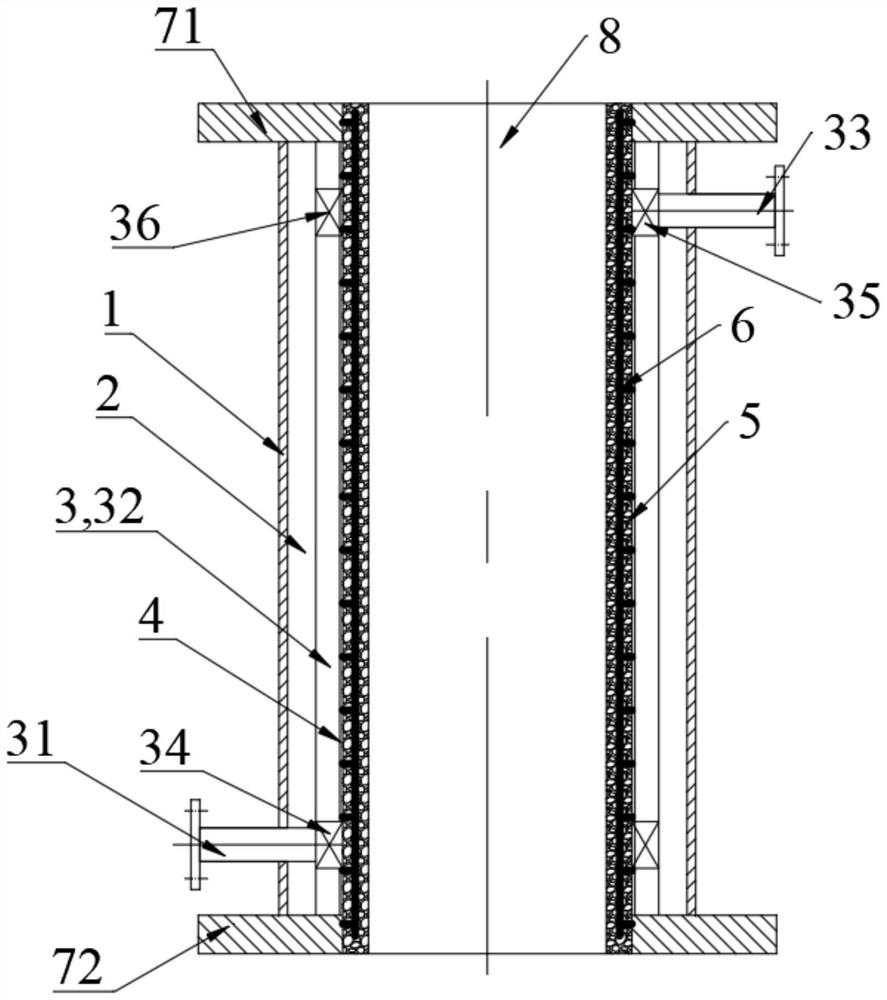

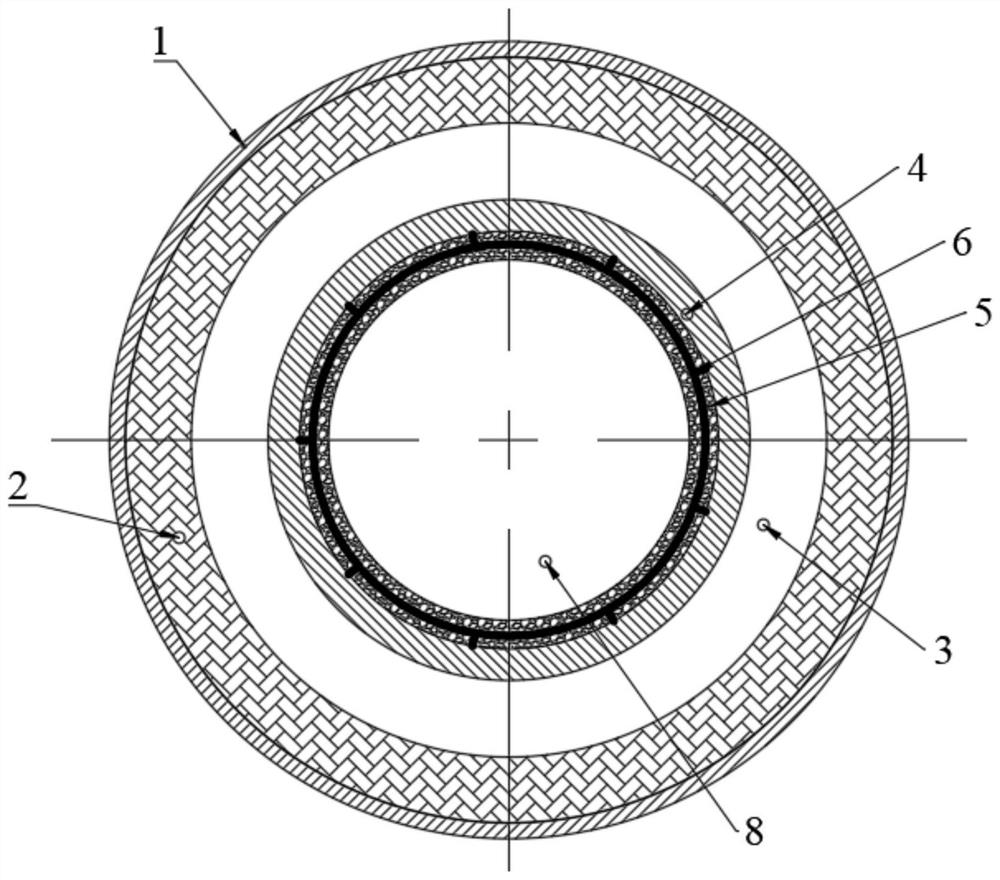

Temperature-resistant anti-corrosion lining coating for riser heat exchanger and construction method thereof

A construction method and technology of heat exchangers, which are applied in coatings, devices for coating liquids on surfaces, and pre-treated surfaces, etc., can solve problems such as poor heat transfer performance, potential safety hazards, and black smoke, so as to prevent rising Damaged tube heat exchanger, improved safety and stability, smooth surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

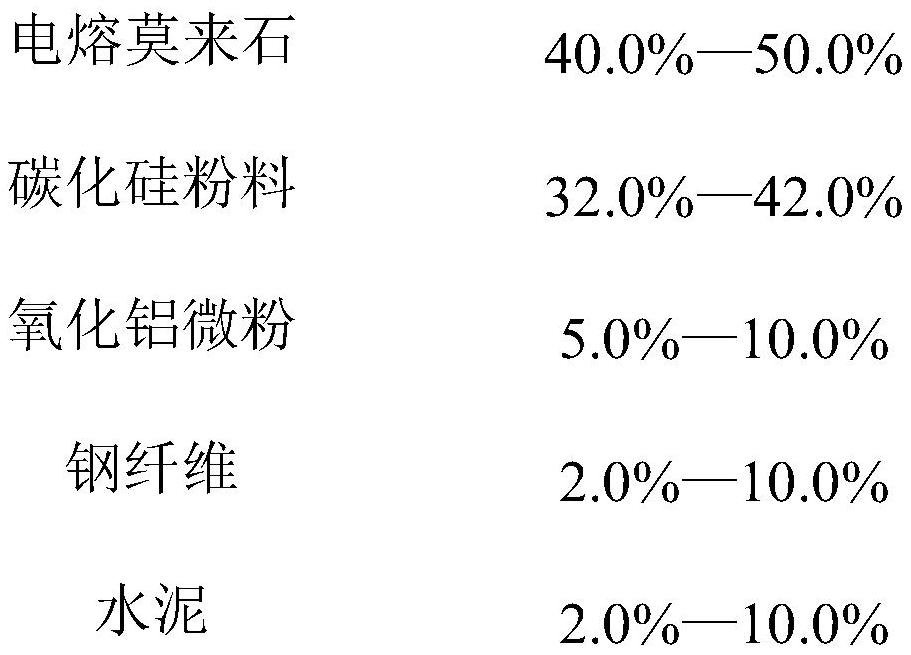

Embodiment 1

[0033] Calculated on the basis of 100kg of solid raw materials, fused mullite, silicon carbide powder, alumina micropowder, steel fiber, and cement, 42.5kg of fused mullite, 42.0kg of silicon carbide powder, 5.6kg of alumina micropowder, 3.5kg of steel fiber, 6.4kg of cement, and 5.2kg of silica sol; 2 o 3 -SiO 2 The content is not less than 98.2%; the SiC content in the silicon carbide powder is 97%, and the particle size of the silicon carbide powder is 200 mesh; the alumina micropowder is α-Al 2 o 3 , the particle size of alumina micropowder is 800 mesh, α-Al 2 o 3 The content is 99.0%; the diameter of the steel fiber is 0.5mm, the length is 3.0mm-5.0mm stainless steel filament; the SiO in the silica sol 2 The content is 30%.

[0034] When preparing this kind of lining coating, pour the solid raw materials fused mullite, silicon carbide powder, alumina micropowder, steel fiber, and cement into the mixer, stir evenly, and pour the mixed solid mixture into the silicon s...

Embodiment 2

[0036] Calculated on the basis of 100kg of solid raw material fused mullite, silicon carbide powder, alumina micropowder, steel fiber and cement, 48.0kg fused mullite, 32.0kg silicon carbide powder, 7.0kg alumina micropowder, 7.5kg of steel fiber, 5.5kg of cement, and 6.0kg of silica sol; 2 o 3 -SiO 2 The content is not less than 98.2%; the SiC content in the silicon carbide powder is 97%, and the particle size of the silicon carbide powder is 200 mesh; the alumina micropowder is α-Al 2 o 3 , the particle size of alumina micropowder is 800 mesh, α-Al 2 o 3 The content is 99.0%; the diameter of the steel fiber is 0.5mm, the length is 3.0mm-5.0mm stainless steel filament; the SiO in the silica sol 2 The content is 30%.

Embodiment 3

[0038] Calculated on the basis of 100kg of solid raw materials, fused mullite, silicon carbide powder, alumina micropowder, steel fiber, and cement, 44.8kg of fused mullite, 36.6kg of silicon carbide powder, 7.5kg of alumina micropowder, 5.7kg of steel fiber, 5.4kg of cement, and 6.8kg of silica sol; 2 o 3 -SiO 2 The content is not less than 98.2%; the SiC content in the silicon carbide powder is 97%, and the particle size of the silicon carbide powder is 200 mesh; the alumina micropowder is α-Al 2 o 3 , the particle size of alumina micropowder is 800 mesh, α-Al 2 o 3 The content is 99.0%; the diameter of the steel fiber is 0.5mm, the length is 3.0mm-5.0mm stainless steel filament; the SiO in the silica sol 2 The content is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com