Pot-type carbon calciner

A calcination furnace and carbon technology, applied in the field of calcination kilns, can solve the problems of low thermal efficiency and insufficient utilization of waste heat, etc., and achieve the effects of high automation, energy saving and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

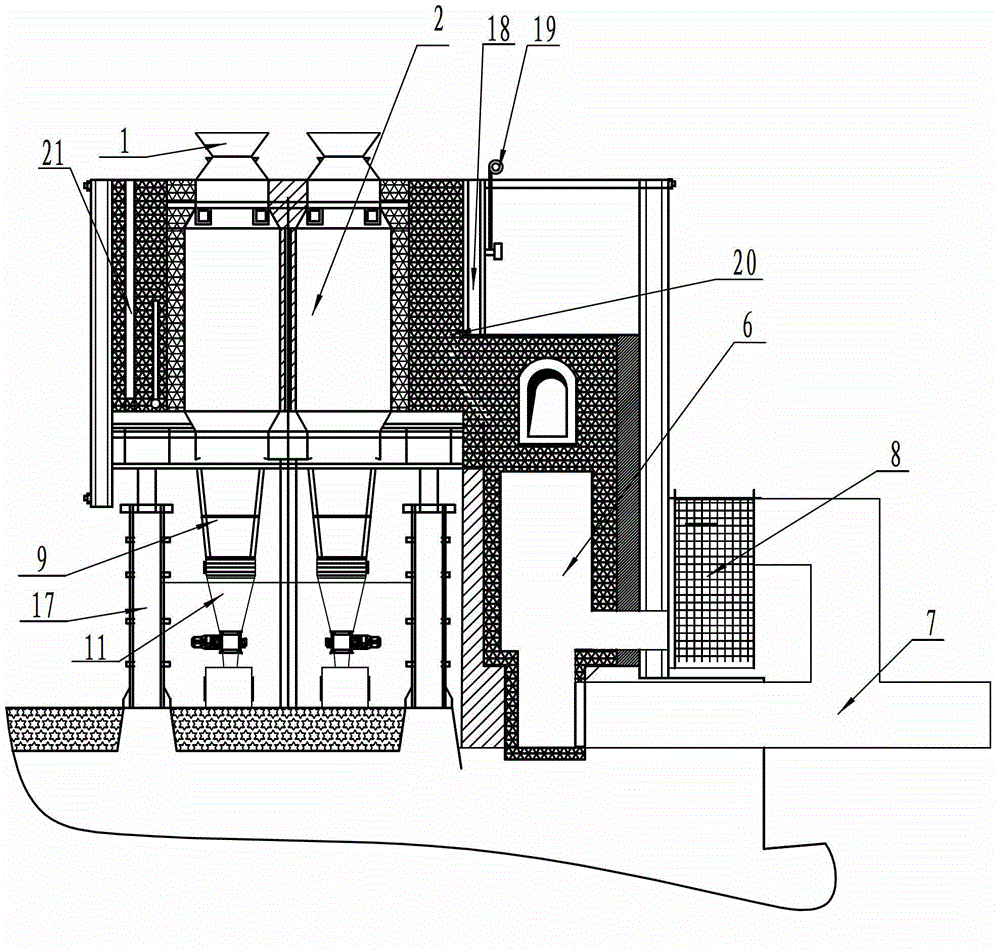

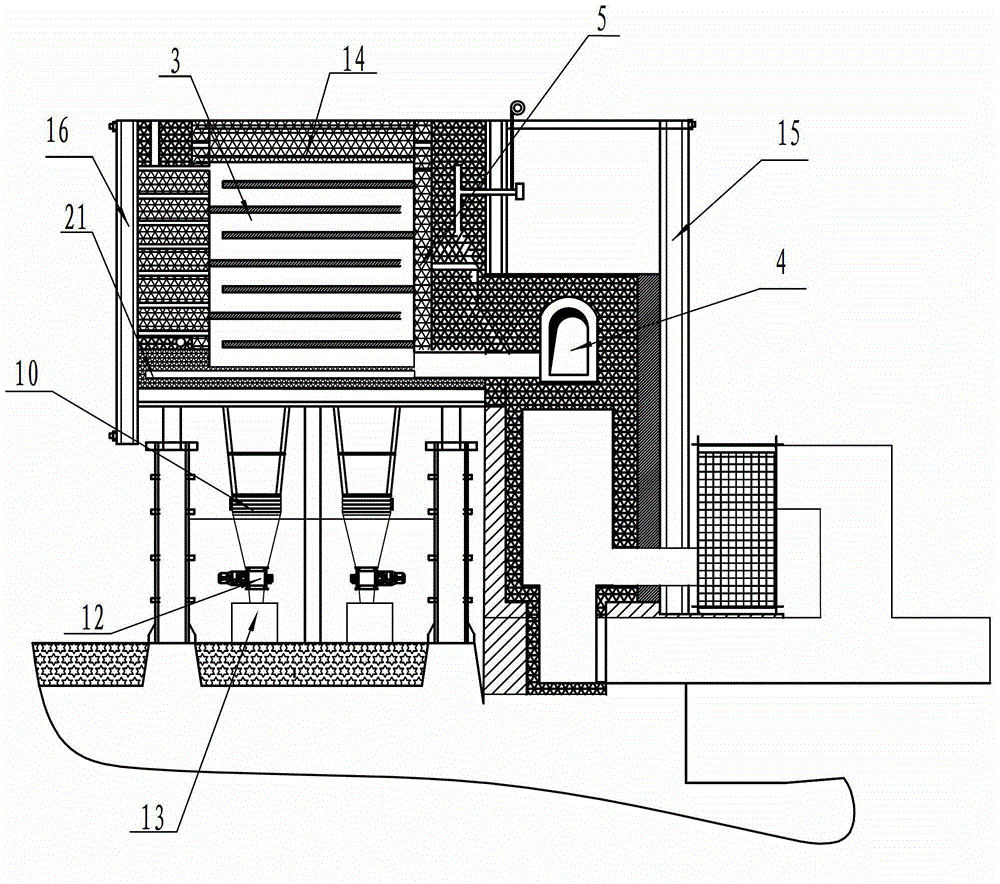

Embodiment 1

[0018] Embodiment 1, a tank-type carbon calcination furnace, every four calcination tanks 2 and furnace walls with heating channels on both sides of the tank form a combustion chamber, and there are expansion joints and collection flues 4 between each combustion chamber, There are 8-10 layers of fire channels 3 on the furnace wall with heating channels. The fire channels communicate with the preheating air channels. The calcination tank is connected to the discharge tank, and there is an interlayer cooling water jacket 9 on the periphery of the discharge tank. Its characteristics are: the entire The calciner is composed of 18 combustion chambers arranged in a line and a total of 72 calciner tanks. The length of the calciner tank is 2180mm, the width is 360mm, and the height is 5576mm. The front wall of the calcination furnace is equipped with a large tool holder 15 for protecting the furnace, and the rear wall is provided with a furnace protection frame 16. The bottom of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com