Quartz tube cleaning device and cleaning method

A technology for cleaning devices and quartz tubes, applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of increased energy consumption, scratches on the outer wall of the quartz tube, damage to the turntable, etc., and achieve economical use. Quantity, efficient cleaning operations, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

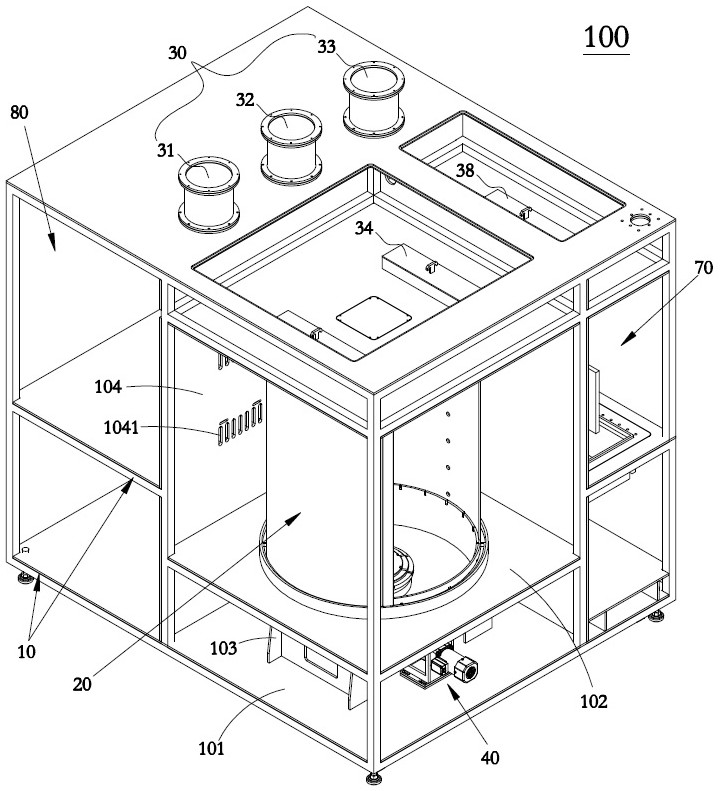

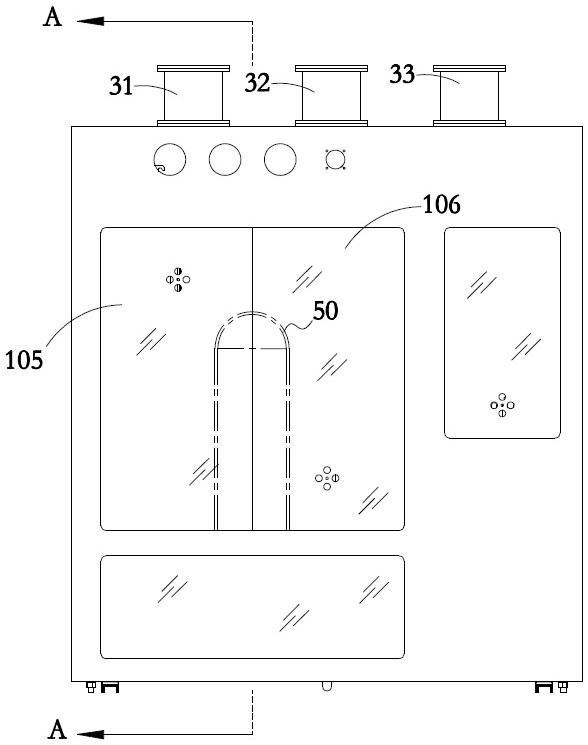

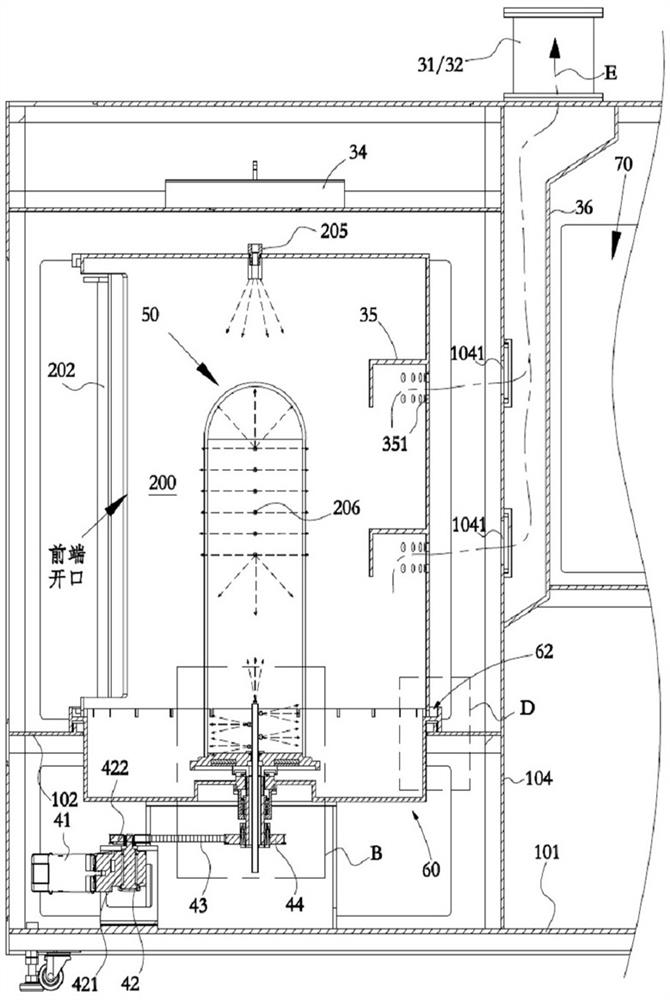

[0042] ginseng Figure 1 to Figure 10 A specific embodiment of a quartz tube cleaning device 100 of the present invention is shown. The quartz tube cleaning device 100 cleans and dries the vertically oriented quartz tube with one end open or two open ends, and is especially suitable for the chemical vapor phase used in the preparation of wafers with a size of 8 inches and above. Cleaning of bell-type quartz tubes with an open structure at only one end commonly used in semiconductor device manufacturing equipment such as deposition (CVD), physical vapor deposition (PVD), diffusion equipment (Diff) or film formation equipment (T / F) and drying treatment.

[0043] combine Figure 8 and Figure 9 As shown, in this embodiment, the quartz tube cleaning device 100 includes: a cleaning cover 20 with an open bottom, and a base 60 that is movably plugged and assembled with the cleaning cover 20 in the vertical direction, and is arranged in the base 60 and clamped The carrying platfor...

Embodiment 2

[0062] Based on the technical solution contained in the quartz tube cleaning device disclosed in the first embodiment, this embodiment discloses a quartz tube cleaning method based on the quartz tube cleaning device shown in the first embodiment. In the quartz tube cleaning method, the quartz tube cleaning device 100 as described in the first embodiment is used to sequentially clean and dry the inverted quartz tube.

[0063] Specifically, in this embodiment, the quartz tube 50 is embedded on the carrier platform 21 in an upside-down state, and the first nozzle 205, the second nozzle 206, and the third nozzle 208 can simultaneously spray deionized water (DIW) or contain cleaning agent deionized water, the quartz tube 50 can be slowly rotated in a vertical posture at a speed of 5 to 10 revolutions per minute driven by the carrying platform 21, and the cleaning process is performed for 5 to 10 minutes. After the cleaning process is finished, switch to the gas supply mode under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com