Winding equipment for motor stator core

A motor stator and stator core technology, applied in the field of machinery, can solve the problems of poor air permeability of silicon steel sheet, low self-heating efficiency, and affecting the winding and forming effect of stator core, so as to achieve the effect of improving the fit and cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

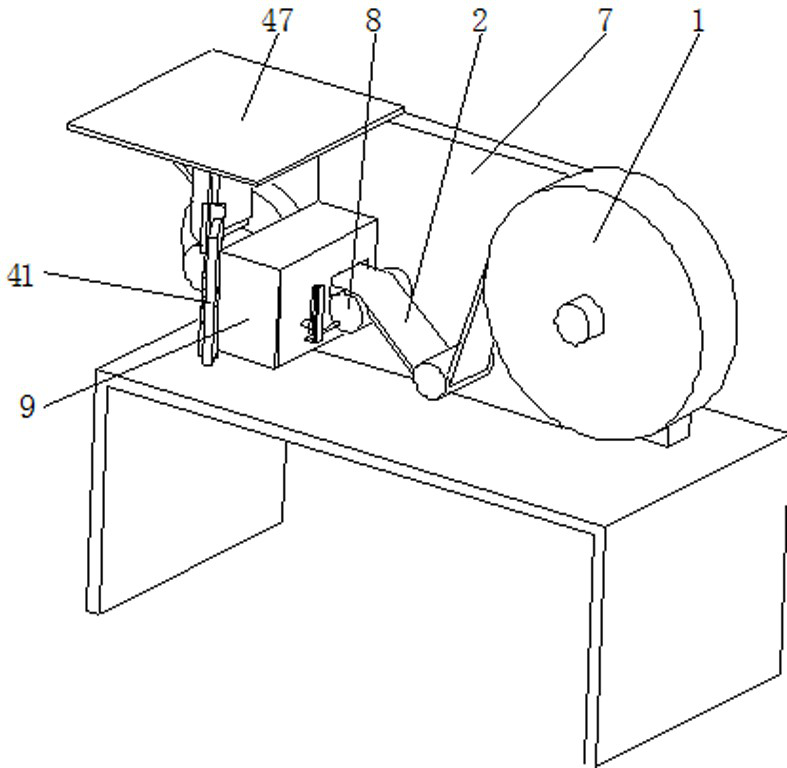

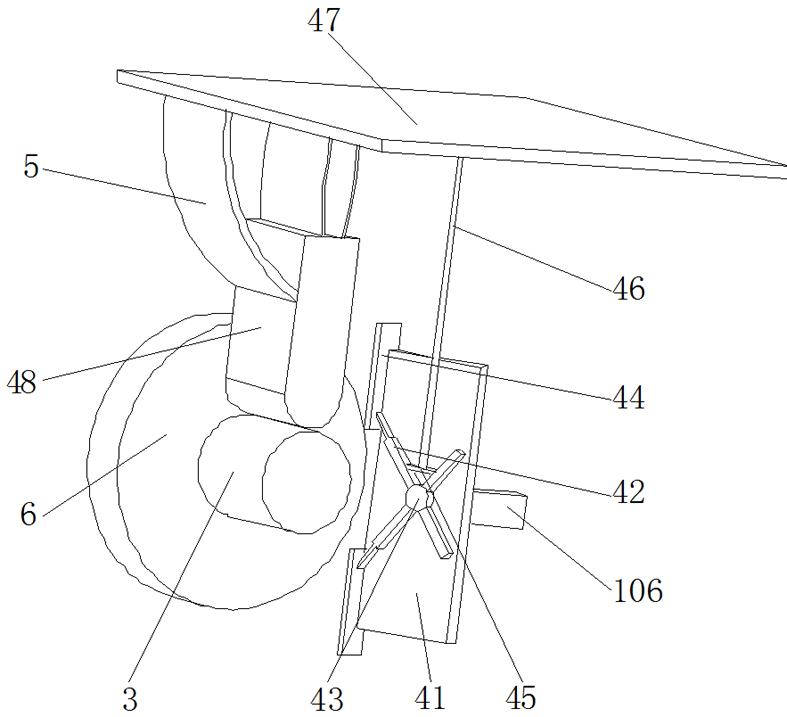

[0029] see Figure 1-6 The present invention provides a technical solution: a winding device for a motor stator core, comprising a winding machine 1 and a stator core 3, an automatic adjustment mechanism is arranged outside the stator core 3, and the automatic adjustment mechanism includes a ventilation plate 41, Telescopic rod 42, rotating column 43, slide plate 44, pull plate 45, pull rod 46, support plate 47 and pressing block 48, telescopic rod 42 runs through and is slidably installed on rotating column 43, and rotating column 43 is rotatably installed on ventilation plate 41 , the top of the telescopic rod 42 is rotatably mounted on the slide plate 44, the slide plate 44 is slidably mounted on the air outlet end of the ventilation plate 41, the pull plate 45 is movably mounted on the outer wall of the telescopic rod 42, the bottom of the pull rod 46 is embedded in the top of the pull plate 45, and the top of the pull rod 46 Embedded in the bottom of the support plate 47,...

Embodiment 2

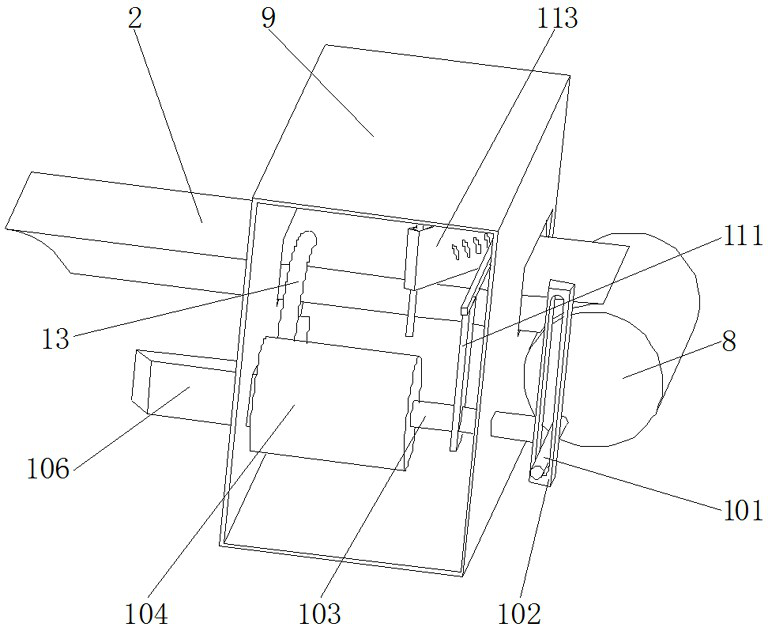

[0032] Such as image 3 , Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, in this embodiment, a cleaning mechanism is provided inside the cleaning box 9, and the cleaning mechanism includes a connecting rod 111, a cleaning column 112, a cleaning scraper 113 and a limit post 114, and one end of the connecting rod 111 Fixedly installed on the push rod 103, the other end of the connecting rod 111 is rotatably installed on the cleaning column 112, the cleaning scraper 113 is embedded on the cleaning column 112, the cleaning scraper 113 is set in a hollow shape, and the inner wall of the cleaning scraper 113 is slidably installed on the On the outer wall of the limiting column 114, the cleaning scraper 113 is arranged in an inclined shape, which can effectively increase the cleaning area of the cleaning scraper 113 and improve the cleaning efficiency. The top of the limiting column 114 is embedded on the inner wall of the cleaning box 9 top, and the cleaning scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com