Pearl and traditional Chinese medicine eczema-preventing regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and traditional Chinese medicine, applied in the field of textile fibers, can solve the problems of large particle size of pearl powder, influence of product quality, and easy damage of traditional Chinese medicine ingredients by acid and alkali, and achieves good affinity, ideal effect, and enhanced lipophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of pearl powder

[0036] After the raw pearls are selected and cleaned, they are mixed with water and placed in a stirring ball mill, and the pearls are coarsely crushed to about 5 μm by the pressure and shear force generated. Then add water and stir to form a 25-40% slurry, and send it into the high-pressure tank of the high-pressure expansion equipment. The steam pressurizes the slurry, and then enters the expansion chamber through the expansion valve and returns to the normal condition. Repeat at least three times. Repeated high-pressure expansion for many times - after decompression to conventional conditions, the pearl layer will expand between the layers, easy to loosen, and then grind by jet crushing technology or wet grinding and crushing method. The fineness of the obtained pearl powder reaches D95≤0.1 μm, and the degree of dispersion is greater than 90%.

[0037] If the particle size of the powder added to the fiber is large, it will not only bloc...

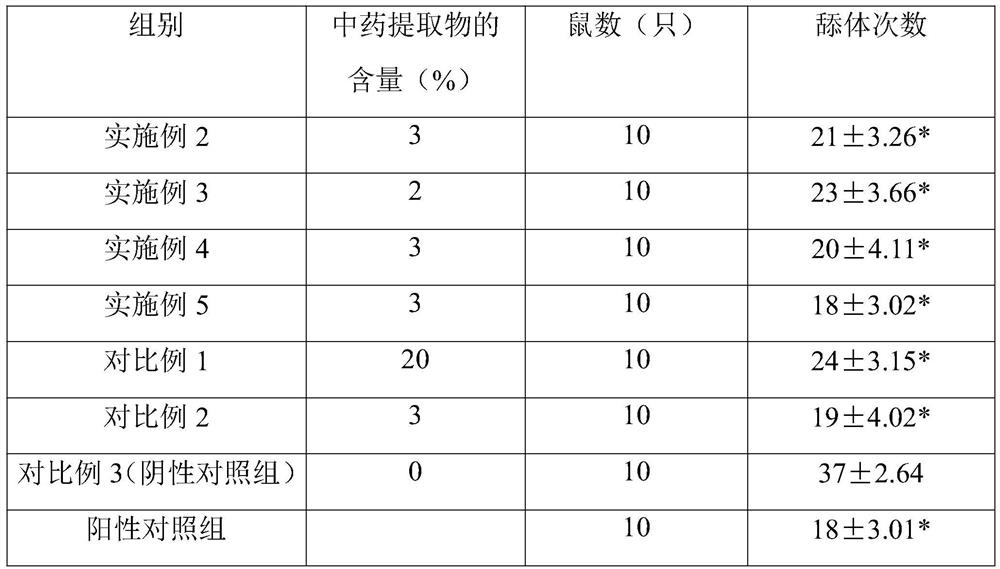

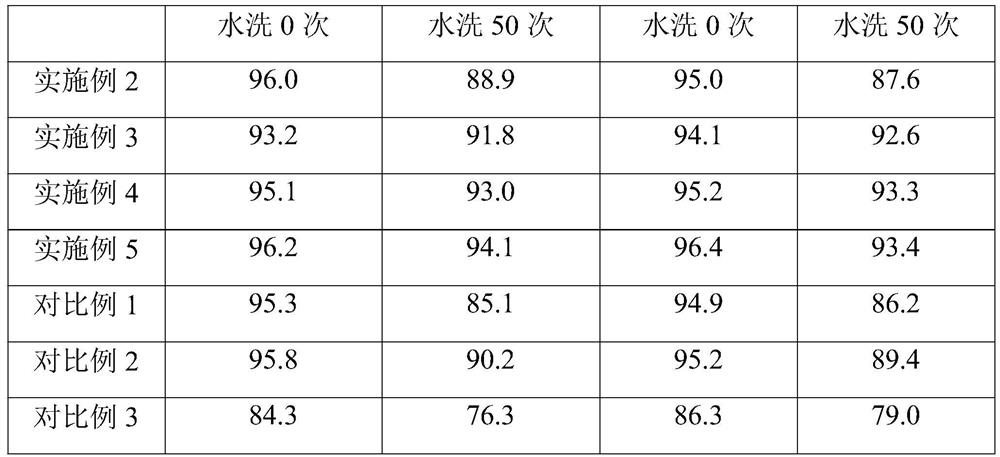

Embodiment 2

[0039] Mix 1.95kg matrine, 0.9kg Kochia saponins, and 0.15kg puerarin into 3L of water, mix 6.9kg palm oil and 0.1kg HLB of triglycerides to prepare an oil phase, and stir Next, the water phase is added into the oil phase to prepare the Chinese medicine extract microemulsion. 4 kg of pearls were crushed according to the crushing method in Example 1 to prepare pearl powder, and the fineness of the pearl powder was D95≤0.1 μm.

[0040] Disperse 0.02kg of toluene diisocyanate and 0.7g of dibutyltin dilaurate in water to form a crosslinking agent solution, heat 0.21kg of polyethylene glycol with a molecular weight of 400 to 60°C to melt, and micronize the pearl powder and traditional Chinese medicine extract After the milk is mixed, it is dispersed in molten polyethylene glycol, stirred for 12 hours, immersed in the cross-linking agent solution, and dried to obtain the inner layer of pearl powder and Chinese medicine extract microemulsion, and the outer layer of polyethylene glyco...

Embodiment 3

[0043] Mix 1kg matrine, 0.8kg Kochia saponin, and 0.2kg puerarin into 2L water to prepare the water phase, mix 2.9kg soybean oil and 0.1kg HLB of 6 sucrose ester to prepare the oil phase, and stir The water phase is added into the oil phase to prepare the Chinese medicine extract microemulsion. 5.5 kg of pearls were pulverized according to the pulverization method of Example 1 to prepare pearl powder, and the fineness of the pearl powder was D95≤0.1 μm.

[0044] Disperse 0.02kg of triisocyanate and 0.7g of dibutyltin dilaurate in water to form a cross-linking agent solution, heat 0.075kg of polyethylene glycol with a molecular weight of 600 to 60°C to melt, and microemulsion the Chinese medicine extract and pearl powder After mixing, disperse in melted polyethylene glycol, stir for 5 hours, and immerse in the crosslinking agent solution. After drying, the inner layer is microemulsion of pearl powder and traditional Chinese medicine extract, and the outer layer is polyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com