Novel polyethylene core-spun yarn foot pad

A technology of polyethylene and core-spun yarn, which is applied in transportation and packaging, carpets, special positions of vehicles, etc., can solve the problems of practical functional performance limitations, complicated manufacturing process, poor weather resistance, etc., and achieve good protection and improve Production efficiency, anti-skid effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

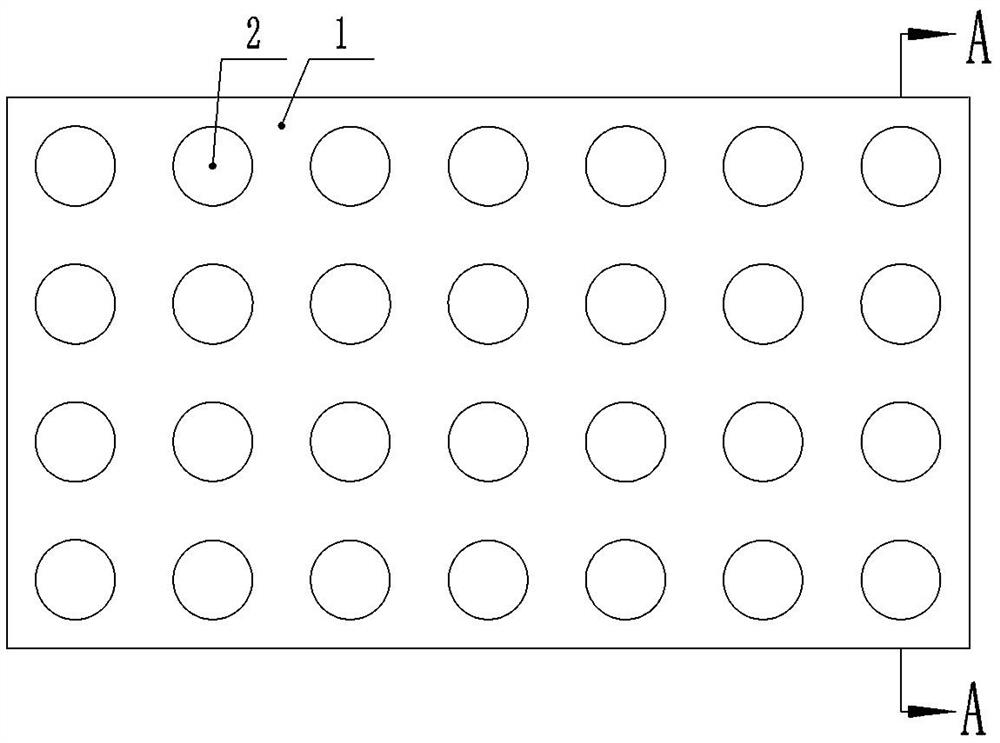

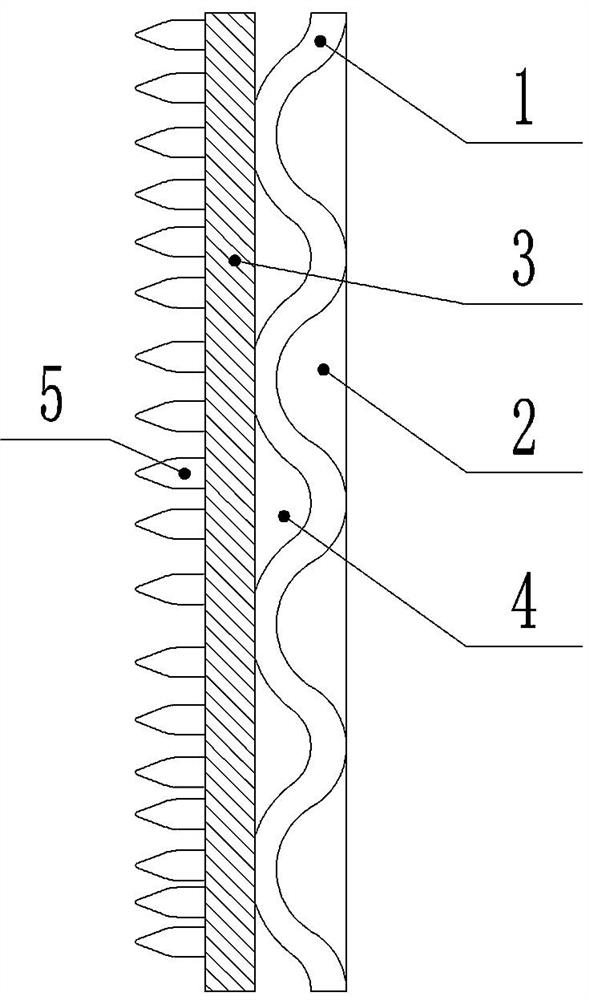

[0033] A new type of polyethylene core-spun yarn foot pad, which is coated with polyethylene on polypropylene yarn or polyester filament, and then woven into a carpet surface layer by tufting equipment or loop pile blanket loom, the carpet surface layer 1 and the bottom surface The layers 3 are composited into one body, and grooves 2 are arranged on the carpet surface layer 1 .

[0034] The carpet surface layer is composed of the following raw materials in parts by weight: 75 parts of polyethylene, 1 part of masterbatch, 15 parts of polypropylene base cloth, 9 parts of polypropylene yarn or polyester filament; polyethylene and color masterbatch are mixed to form The mixed material is then covered with polypropylene yarn or polyester filament by a core-spun drawing machine to form a core-spun yarn, and the drawn core-spun yarn is passed through a tufting device or a loop pile weaving blanket Machine-woven on the polypropylene base cloth, the surface of the carpet surface layer ...

Embodiment 2

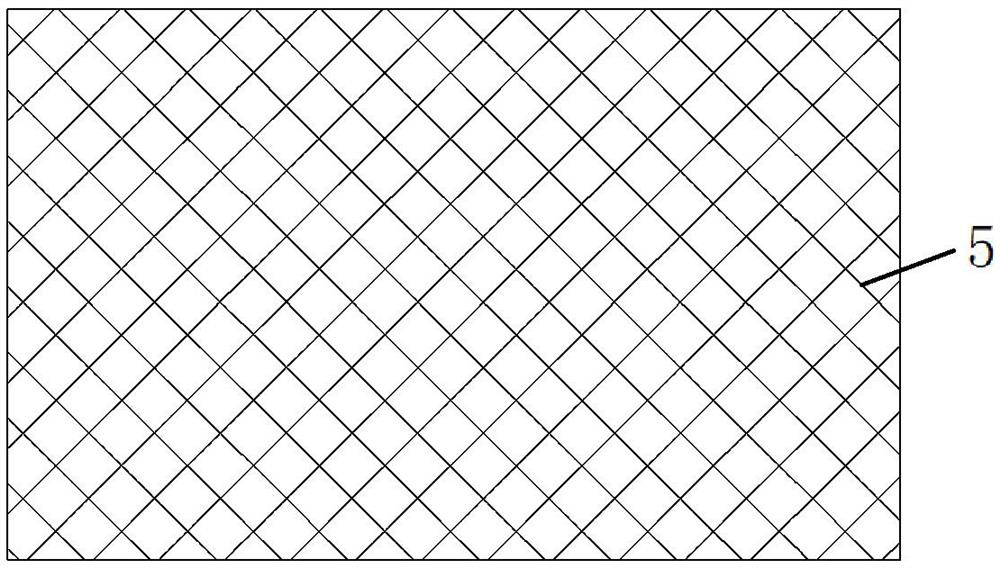

[0040] The difference between embodiment 2 and embodiment 1 is that the anti-slip body is cylindrical. The protruding portion at the end of the anti-skid body is in the shape of a "well" or a "rice".

Embodiment 3

[0042] The difference between embodiment 2 and embodiment 1 is that the anti-slip body is cylindrical. The protruding portion at the end of the anti-skid body is spike-shaped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com