SVPWM harmonic suppression method applied to nine-phase open-end winding motor

A harmonic suppression and winding technology, which is applied in the field of multi-phase motor drive control, can solve the problems of discontinuous pulse signal, high content of low-order harmonics, and large amount of calculation of vector points, so as to achieve strong versatility, improve work safety, The effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The examples described below are only for explaining the present invention and are not intended to limit the present invention.

[0061] A kind of SVPWM harmonic suppression method applied to a nine-phase open-end winding motor proposed by the present invention includes:

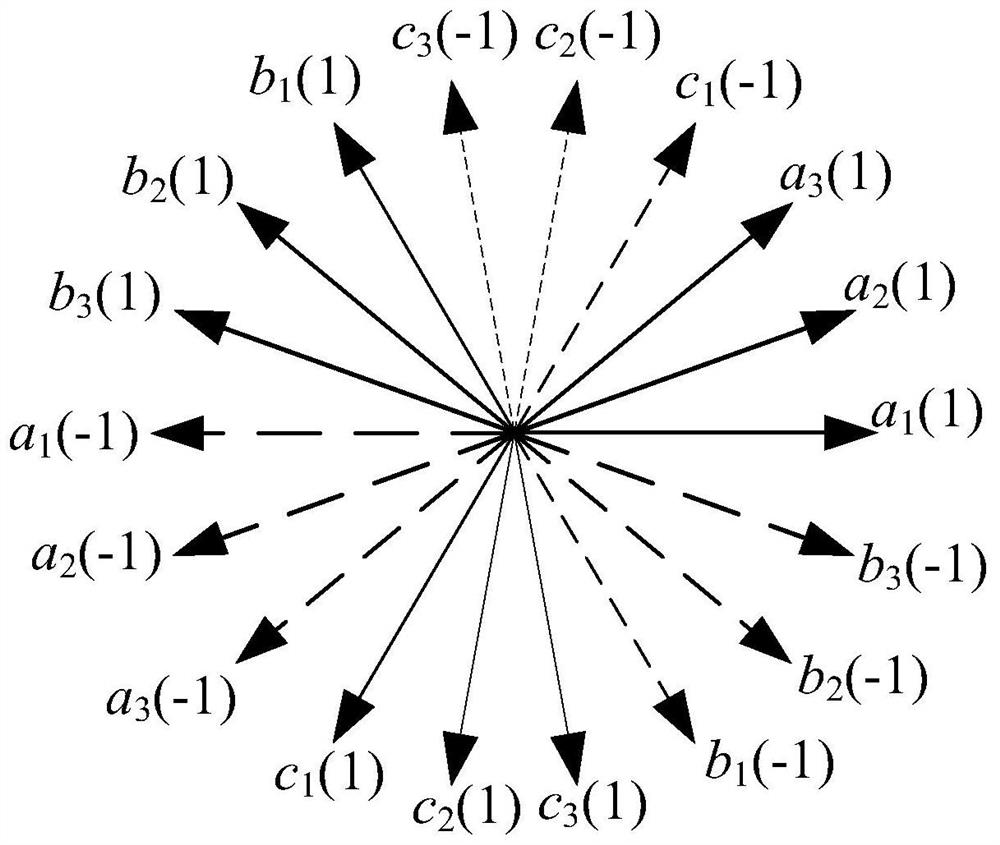

[0062] Step 1. Reconstruct the representation of vector points, and use level states instead of switch states to represent different vector points.

[0063] In one embodiment, step one specifically includes:

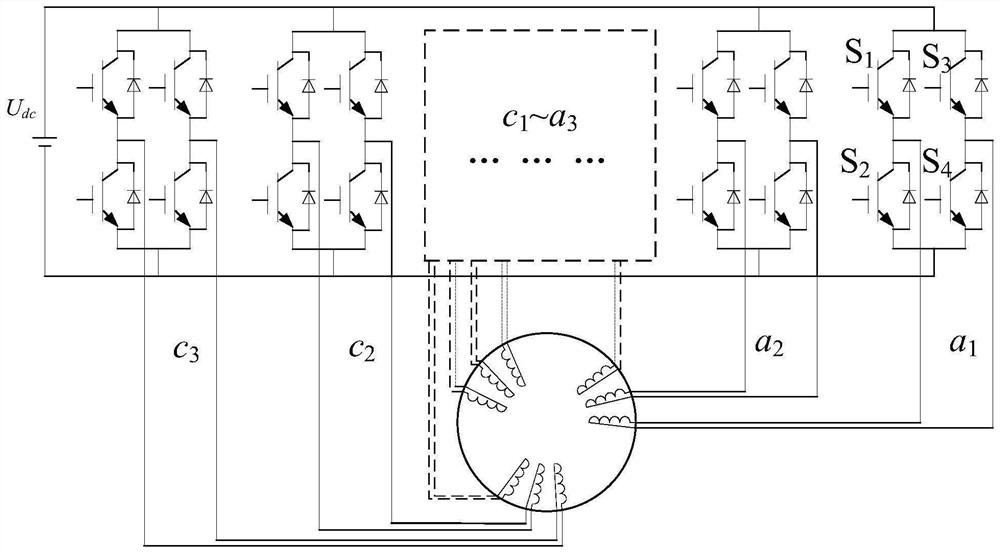

[0064] The H-bridge inverter is actually a dual-inverter structure with a common DC bus, so the corresponding inverter bus voltages at both ends of the winding are the same. The internal relationship between the switch state of the H-bridge inverter and the level state of the winding is analyzed. Such as figure 1 As shown, each phase winding corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com