Flip light-emitting diode chip and preparation method thereof

A technology for light-emitting diodes and chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of Bragg mirror exposure, affecting the luminous efficiency of flip-chip light-emitting diode chips, affecting the quality of Bragg mirrors, etc., to ensure luminous efficiency and Reliability, quality of protection, good effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objects, technical solutions, and advantages of the present invention, the present disclosure will be further described in detail below with reference to the accompanying drawings.

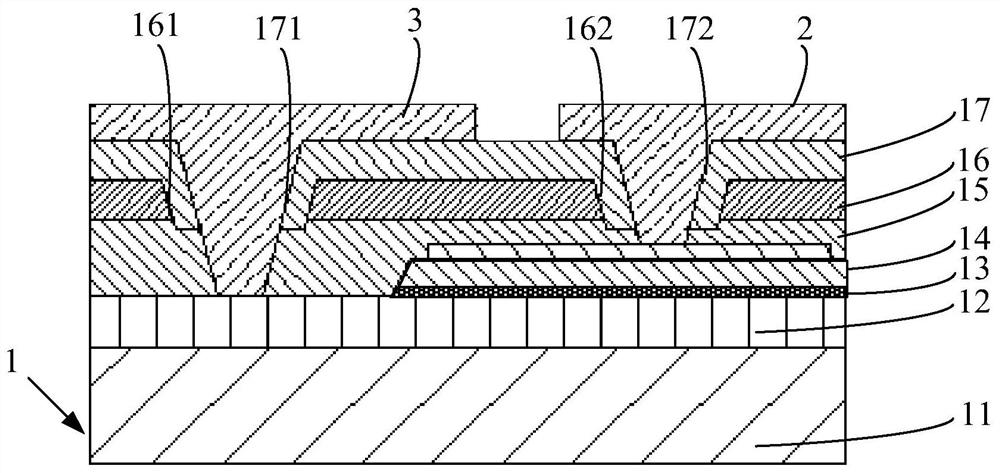

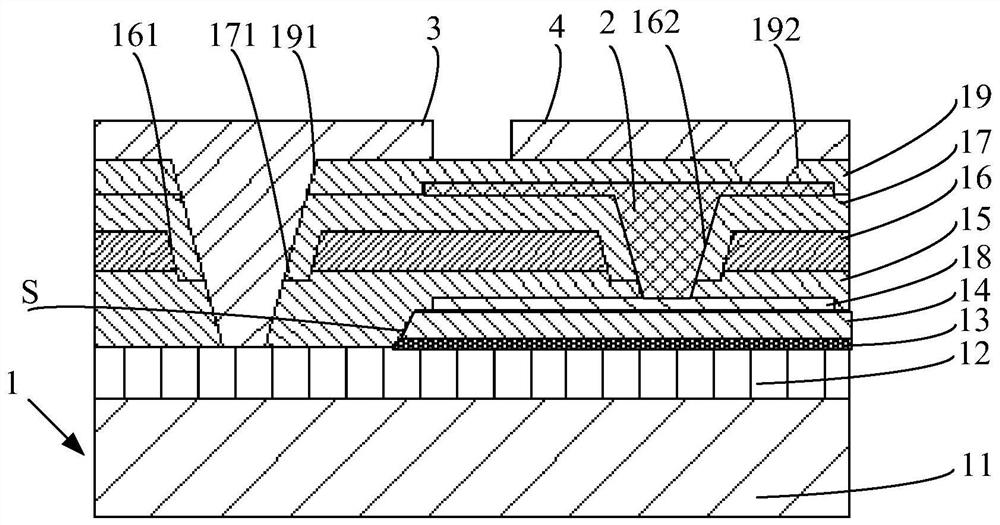

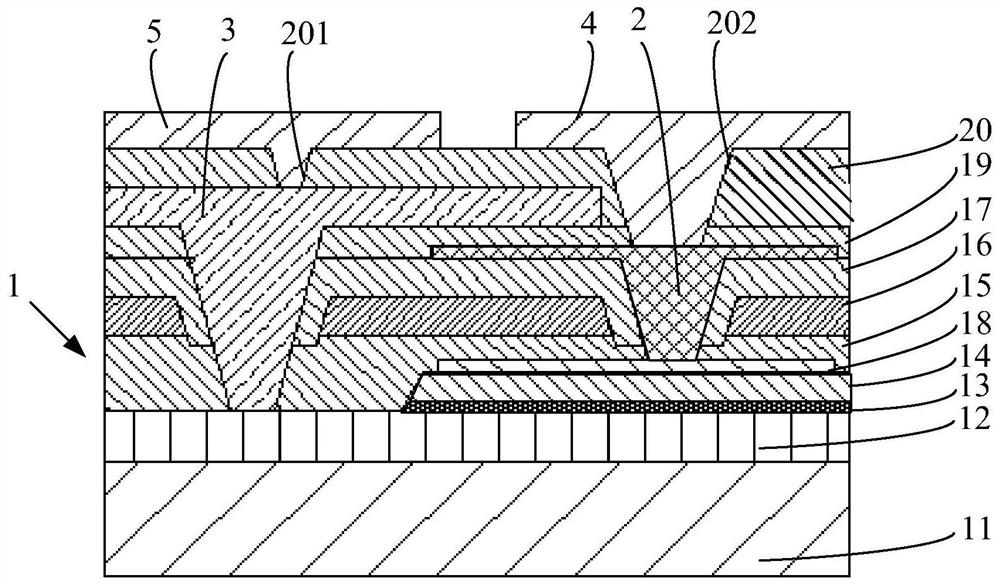

[0036] figure 1 It is a schematic structural diagram of a flip-loaded light-emitting diode chip provided by the embodiment of the present disclosure, such as figure 1 Design, the present disclosure provides a flip-loaded light-emitting diode chip, and the light-emitting diode chip includes an epitaxial sheet 1, the primary P electrode 2 and the primary N electrode 3, and the epitaxial sheet 1 includes a substrate 11 and sequentially laminated in a substrate 11. The upper N-type layer 12, the light-emitting layer 13, the p-type layer 14, the corrosion cutoff layer 15, the Prague mirror 16 and the first insulating protective layer 17.

[0037] The surface of the Prague mirror 16 has a spaced first receiving groove 161 and a second receiving groove 162, and the first receivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com