Novel low-cost composite efficient converter exothermic compound and preparation method thereof

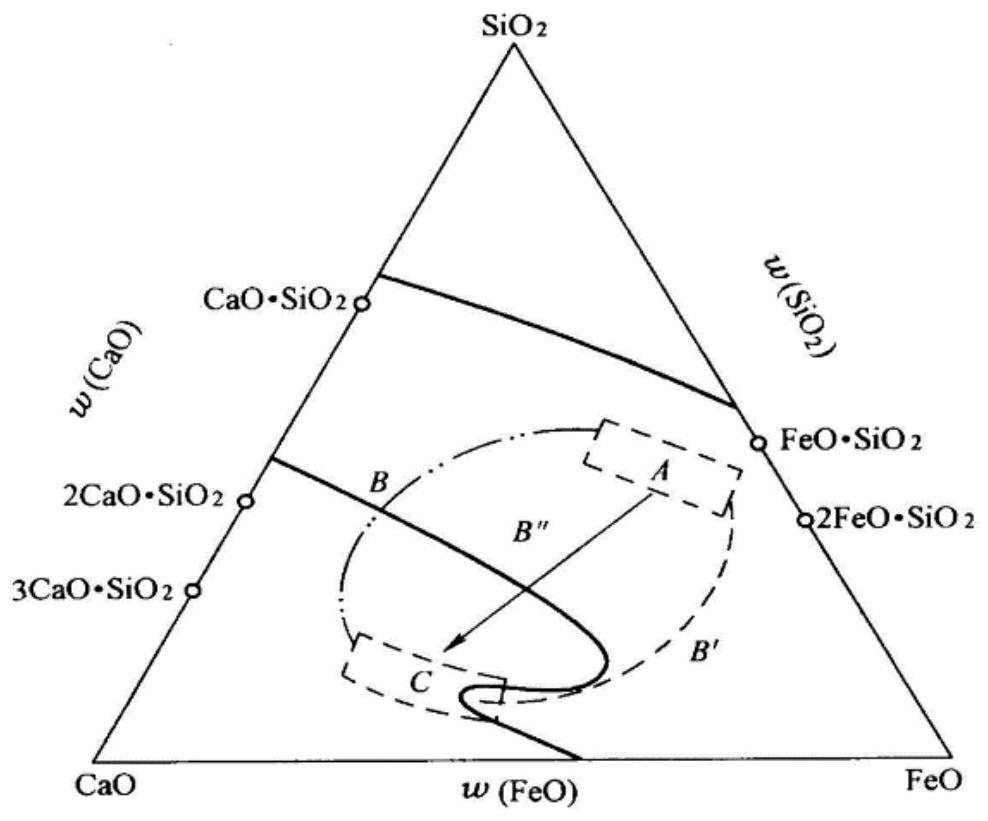

A low-cost, exothermic agent technology, applied in the field of metallurgy, can solve the problems of high raw material cost, unfavorable slagging process, slagging amount, increased heat consumption, etc., to achieve high heating efficiency of products, save production time, and improve heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

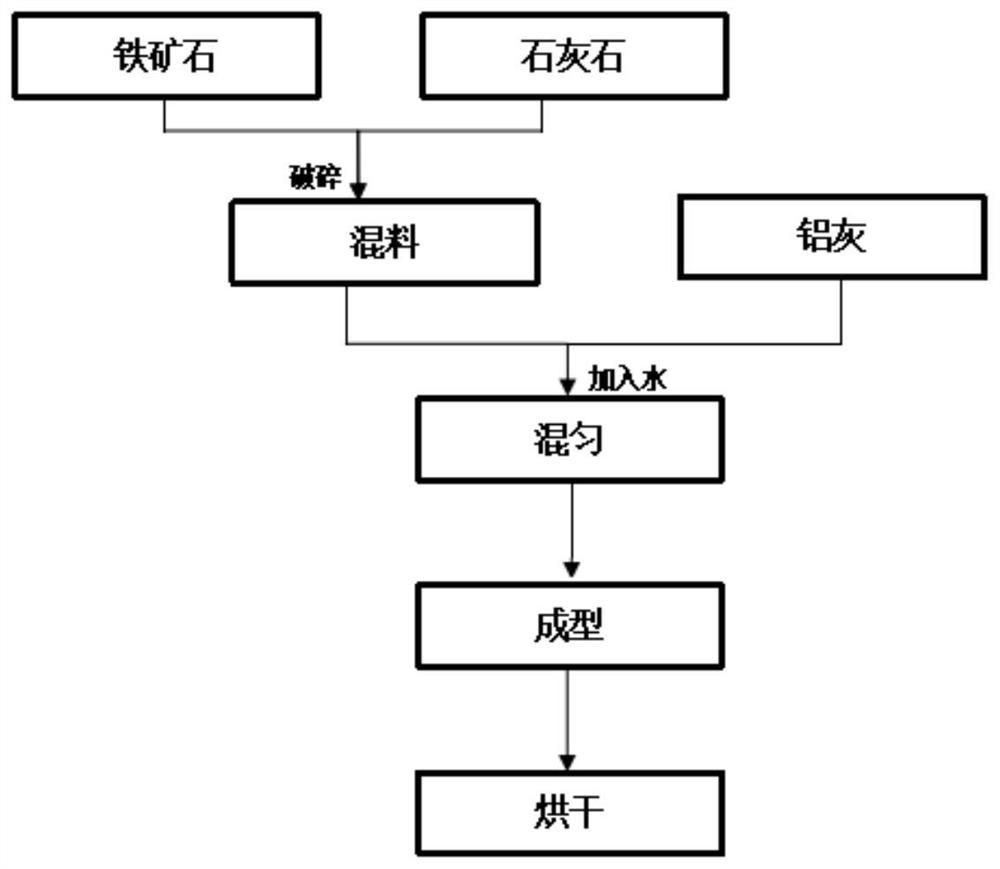

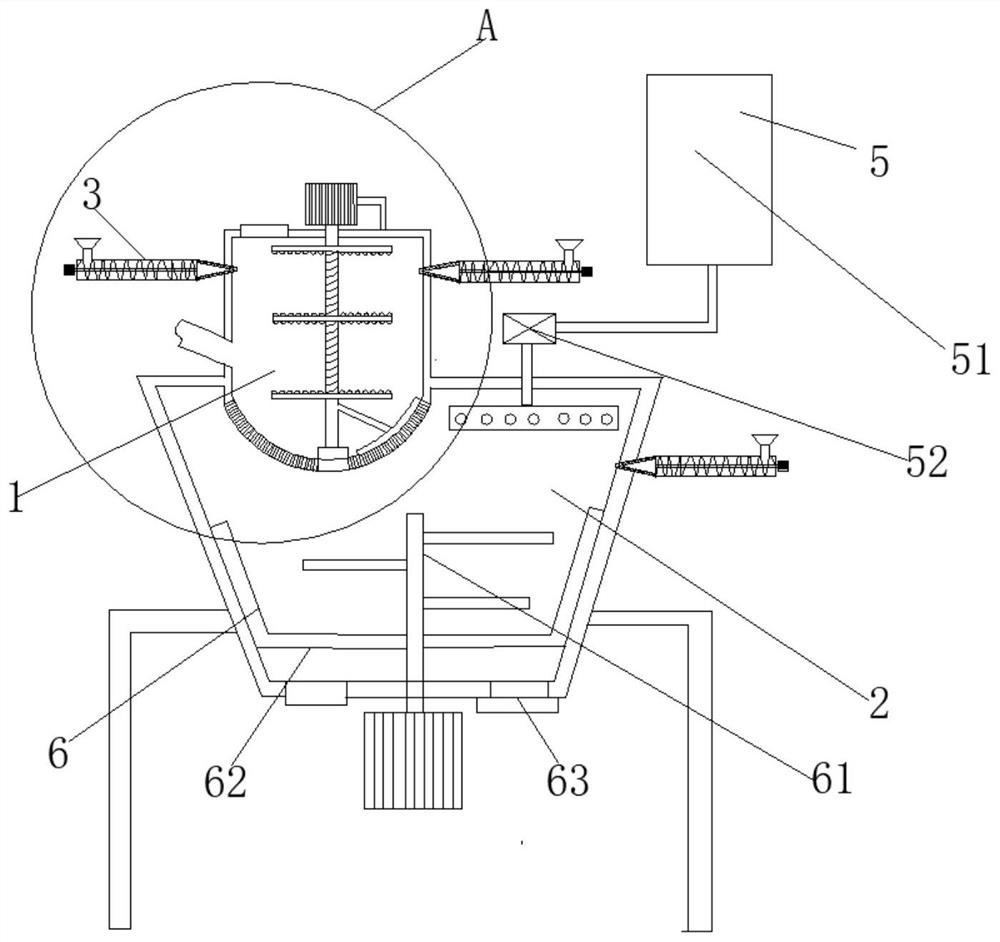

[0053] A method for the preparation of low-cost new composite high efficiency heat preservation agents with a converter, the specific steps are as follows:

[0054] S1: Weighing weight based on 20% to 50% of the aluminum ash, with a weight of iron ore and weight proportional to 10% to 20% limestone;

[0055] S2: The iron ore, limestone weigh in step S1 is broken into powder particles by the ground, and the particle size of the powder particles is ≤ 1 mm, and the particle size> 1 mm powder particles are mixed during the production process. However, the weight ratio must not exceed 5 to 10% of the total weight of the powder particles;

[0056] S3: The aluminum ash and water obtained in step S1 are added to the powder particles of the iron ore and the limestone of the grinding of step S2, and the mixed raw materials are mixed and stirred into the mixed raw material. Gray, iron ore and 8% to 12% of total limestone;

[0057] S4: The mixed feedstock in step S3 is formed into a heat gene...

Embodiment 1

[0065] Using aluminum ash, iron ore and limestone preparation of low-cost new composite high-efficiency heat preservative, where the weight percentage of aluminum ash is 20%, the weight percentage of iron ore is 60%, and the weight percentage of limestone is 20%.

[0066] Among them, aluminum-ash chemistry composition and mass percentage: w (al) is 19.86%, W (Al 2 O 3 ) Is 47.24%, the remaining ingredients are SiO 2 , Cao, MgO, Feo, Mno, NA 2 O And inevitable impurities. The above-mentioned feedstock is prepared, mixed, molded, and manufactured by the preparation method of the present invention.

Embodiment 2

[0068] Using aluminum ash, iron ore and limestone preparation of low-cost new composite high-efficiency heat preservative, where the weight percentage of aluminum ash is 30%, the weight percentage of iron ore is 53%, and the weight percentage of limestone is 17%.

[0069] Among them, aluminum-ash chemistry composition and mass percentage: w (al) is 19.86%, W (Al 2 O 3 ) Is 47.24%, the remaining ingredients are SiO 2 , Cao, MgO, Feo, Mno, NA 2 O And inevitable impurities. The above-mentioned feedstock is prepared, mixed, molded, and manufactured by the preparation method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com