Method for preparing 6-aminocapronitrile

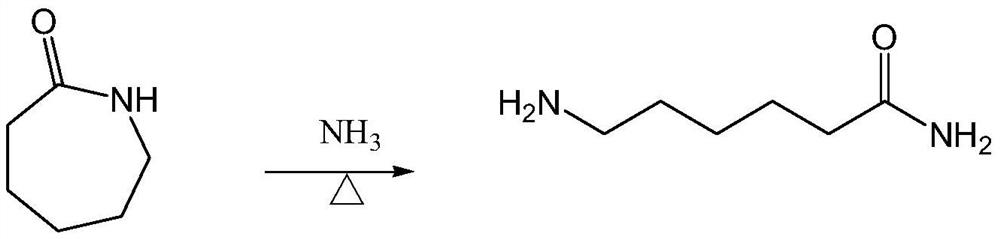

A technology of aminocapronitrile and aminocaproamide, which is applied in the field of two-step preparation of the key intermediate 6-aminocapronitrile of hexamethylenediamine, which can solve problems such as increased energy consumption, increased polymer, and coking of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

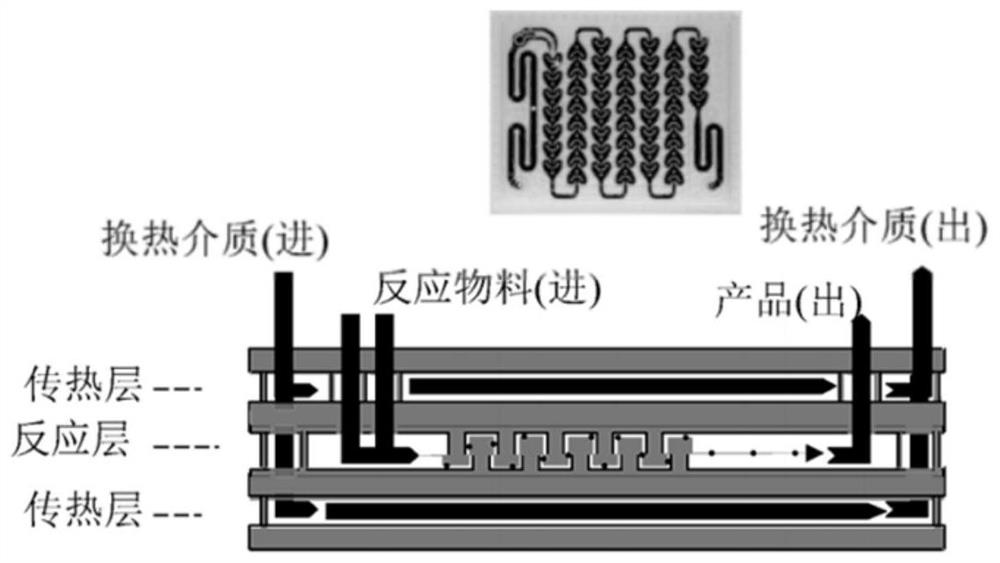

[0054] The method for the synthetic hexamethylenediamine key intermediate 6-aminocapronitrile of the present invention, comprises the steps:

[0055] (1) The raw material caprolactam is transported to different preheaters through a temperature-controlled metering pump and ammonia gas for preheating. The preheating temperature of caprolactam is 280°C, and the preheating temperature of ammonia gas is 350°C. According to the molar ratio of 1:30, the ammonia gas is passed into the microchannel reactor I, and the reaction is carried out at 450°C and 5MPa, and the residence time in the microchannel reactor I is 15s;

[0056] (2) Transport the material obtained after the reaction in step (1) to a gas-liquid separator, and perform gas-liquid separation at 200 ° C. The separated gas phase material ammonia gas is sent to step (1) to continue the reaction, and the liquid phase is separated. The material is 6-aminocaproamide;

[0057] (3) After the 6-aminocaproamide separated from step (...

Embodiment 2

[0060] The method for the synthetic hexamethylenediamine key intermediate 6-aminocapronitrile of the present invention, comprises the steps:

[0061] (1) The raw material caprolactam is transported to different preheaters through a temperature-controlled metering pump and ammonia gas for preheating respectively. The preheating temperature of caprolactam is 300°C, and the preheating temperature of ammonia gas is 350°C. According to the molar ratio of 1:20, the ammonia gas is passed into the microchannel reactor I, and the reaction is carried out at 350°C and 1MPa, and the residence time in the microchannel reactor I is 60s;

[0062] (2) Transport the material obtained after the reaction in step (1) to a gas-liquid separator, and perform gas-liquid separation at 250 ° C. The separated gas phase material ammonia gas is sent to step (1) to continue the reaction, and the liquid phase is obtained by separation. The material is 6-aminocaproamide;

[0063] (3) After the 6-aminocaproa...

Embodiment 3

[0066] The method for the synthetic hexamethylenediamine key intermediate 6-aminocapronitrile of the present invention, comprises the steps:

[0067] (1) The raw material caprolactam is transported to different preheaters through a temperature-controlled metering pump and ammonia gas for preheating respectively. The preheating temperature of caprolactam is 250°C and that of ammonia gas is 200°C. According to the molar ratio of 1:10, the ammonia gas is passed into the microchannel reactor I, and the reaction is carried out at 400°C and 5MPa, and the residence time in the microchannel reactor I is 120s;

[0068] (2) Transport the material obtained after the reaction in step (1) to a gas-liquid separator, and perform gas-liquid separation at 200 ° C. The separated gas phase material ammonia gas is sent to step (1) to continue the reaction, and the liquid phase is separated. The material is 6-aminocaproamide;

[0069] (3) After the 6-aminocaproamide separated from step (2) is pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com