Low-radiation coated hollow glass and coating process thereof

A low-emissivity coating and low-emission technology, applied in the direction of coating, etc., can solve the problems of insulating glass layer structure or installation structure improvement, etc., achieve good low-emission performance and heat insulation performance, good sound insulation, and improve air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

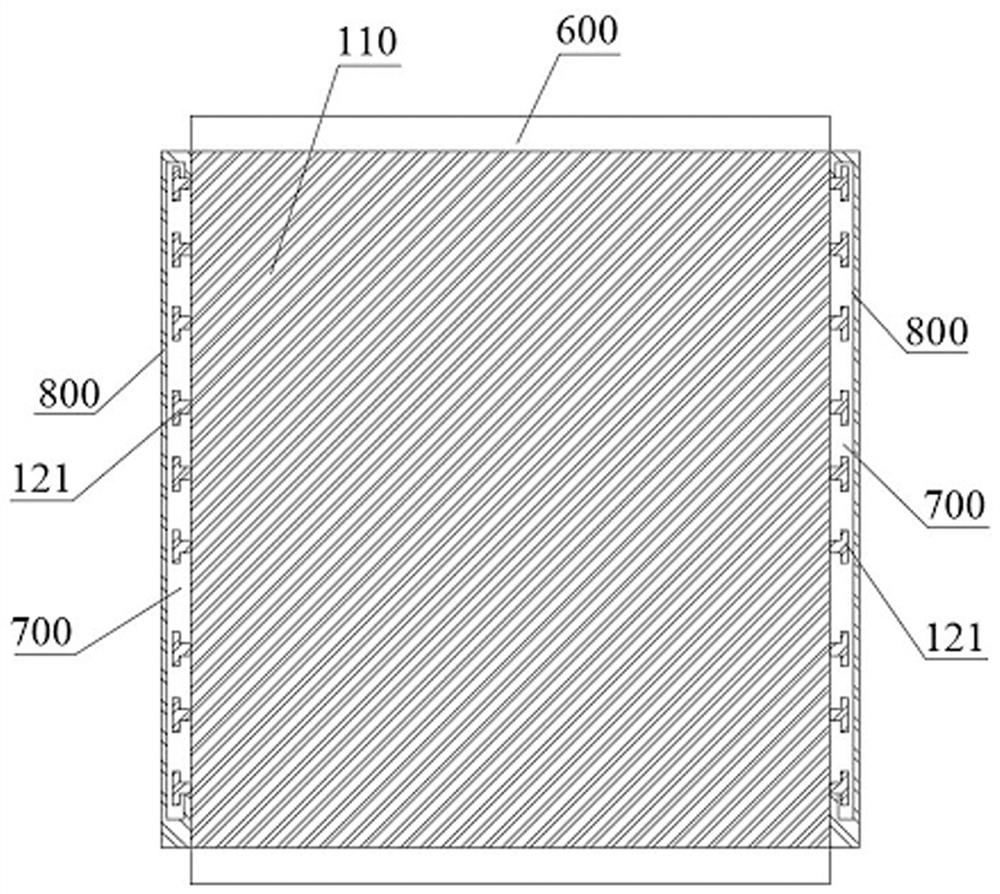

[0038] Such as figure 1 As shown, a low-emissivity coated insulating glass provided in this embodiment includes an outer glass substrate layer 100, a first sputter-deposited nano-film layer 200, a second sputter-deposited nano-film layer 300, The inner glass substrate layer 400, the top and the bottom of the outer glass substrate layer 100 and the inner glass substrate layer 400 are installed with a first reinforcing mechanism 600 through the first sealing member 500, and the two sides of the outer glass substrate layer 100 and the inner glass substrate layer 400 pass through The second sealing member 700 is equipped with a second reinforcement mechanism 800, and the first sealing member 500 and the second sealing member 700 enclose the first sputtering deposited nano-film layer 200 and the second sputtering deposited nano-film layer 300. forming a closed cavity 900;

[0039] The outer glass substrate layer 100 includes a first outer glass substrate 110, a first low-radiation...

Embodiment 2

[0048] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a layer of explosion-proof film layer 140 is provided on the side of the first outer glass substrate 110 away from the first low-emissivity mucous layer 120 . The airtight cavity 900 is filled with dry air or an inert gas, and the inert gas is preferably argon. The explosion-proof film layer 140 is glued on the surface of the first outer glass substrate 110 by pressure-sensitive adhesive, which plays the role of explosion-proof and heat insulation, and can be directly torn off during the use of the insulating glass.

Embodiment 3

[0050] Such as figure 1 As shown, in this embodiment, on the basis of Example 1, the preparation method of the first low-radiation mucous layer 120 and the second low-radiation mucous layer 420 specifically includes the following steps:

[0051] S1. Preparation of matrix film material: according to parts by weight, weigh 135 parts of phenylpropylene, 23 parts of n-butyl methacrylate, 13 parts of acrylic acid, 4 parts of sodium carbonate, 2 parts of sodium lignosulfonate, and 480 parts of deionized water, Stir mechanically at 62°C for 2.5 hours, add dropwise 26wt% sodium hydroxide solution to pH 7~8, vacuum demulsify, filter under reduced pressure, and the obtained filtrate is the matrix membrane material;

[0052] S2. Preparation of radiation-reducing filler: According to parts by weight, 32 parts of inorganic nano-powder with infrared blocking effect, 8 parts of nano-titanium dioxide powder, 7 parts of dispersant, 2.2 parts of light stabilizer, and 48 parts of solvent ethyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com