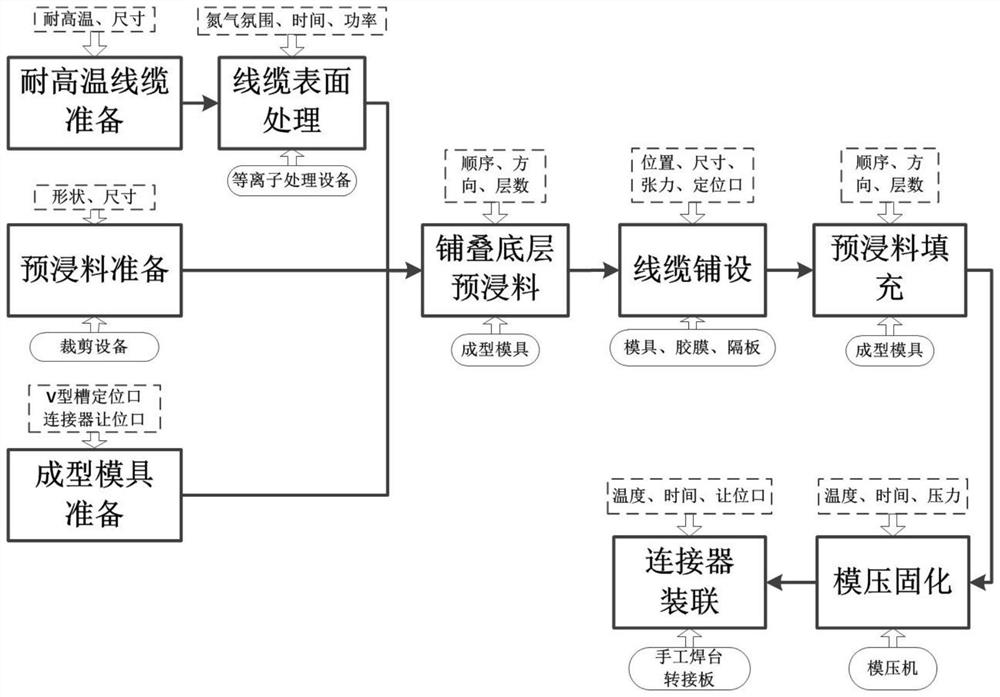

Method for embedding cable assembly into composite material through mold pressing

A composite material and cable assembly technology, applied in the field of cable manufacturing, can solve problems such as hidden quality problems and difficult wiring in small spaces, and achieve the effects of improving bonding strength, saving wiring space, and good batch productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

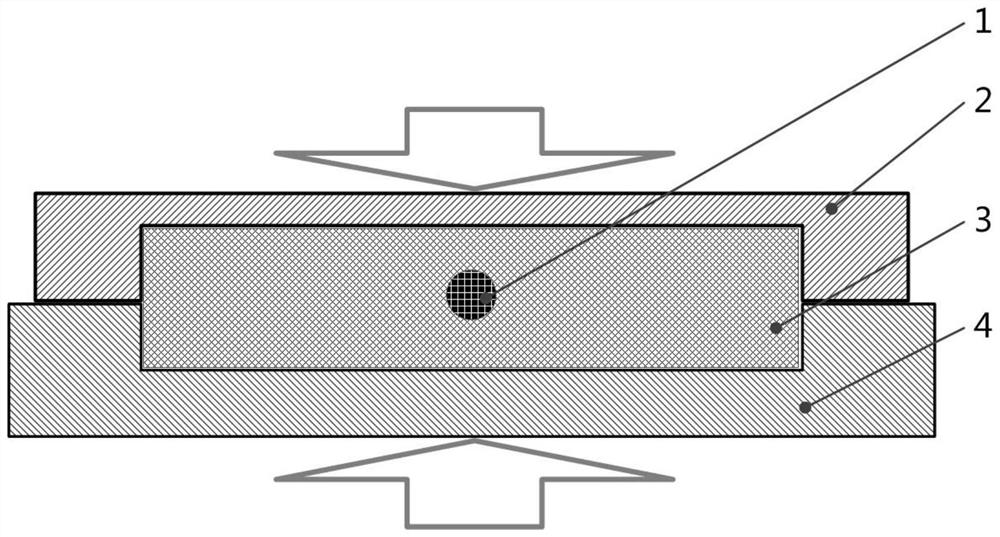

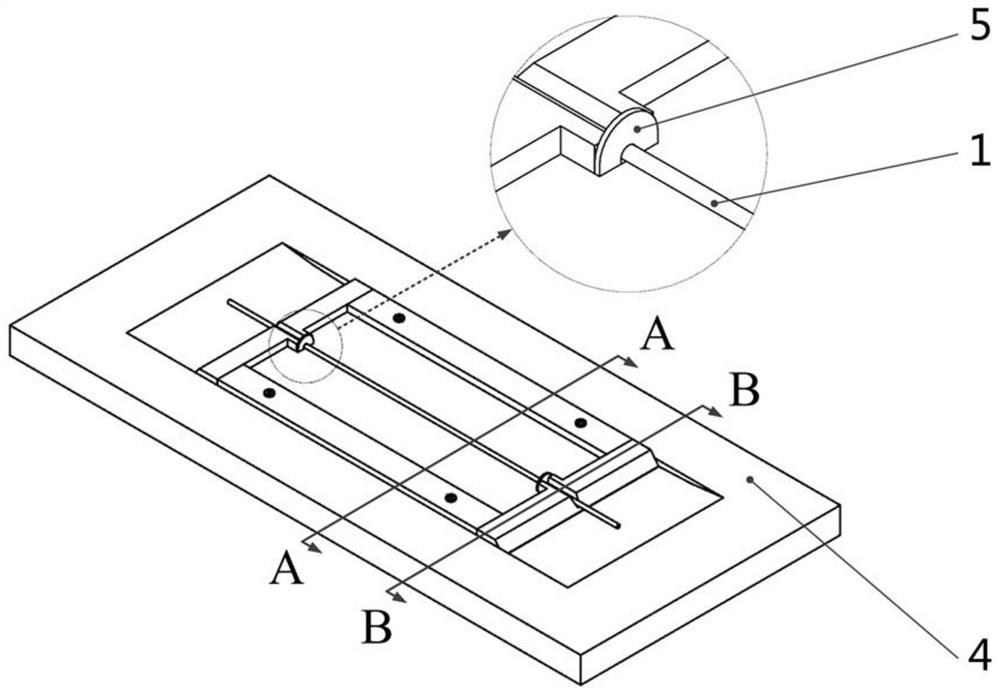

[0017] refer to Figure 1-Figure 6 . According to the present invention, the cable 1 adopts a high-temperature-resistant model whose outer skin is made of polytetrafluoroethylene, and is molded with an upper mold 2 and a lower mold 4 with upper and lower cavities, and the lower mold 4 is designed for forming and connecting The relief boss of the positioning gap of the device 6 is installed, and a V-shaped groove is designed on the frame bearing frame of the cable extension end of the lower mold 4, which is used for centering positioning when the cable 1 is laid; , the skin of the cable 1 is treated with a plasma treatment process to increase its surface energy and improve the bonding strength of the skin and the composite material matrix interface; After drying, fill the cut composite material prepreg 3 into the groove of the lower mold 4, and lay it when laying the bottom prepreg 3 to 1 / 2 the thickness of the groove according to the order, direction, and number of layers of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com