Intelligent casting grinding equipment with learning function

A learning function and casting technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc., can solve the problems of wasting labor costs, long grinding process, and the inability to realize remote data transmission single-chip microcomputer system, etc., to achieve Realize automatic upgrade, improve the yield rate, and realize the effect of remote data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

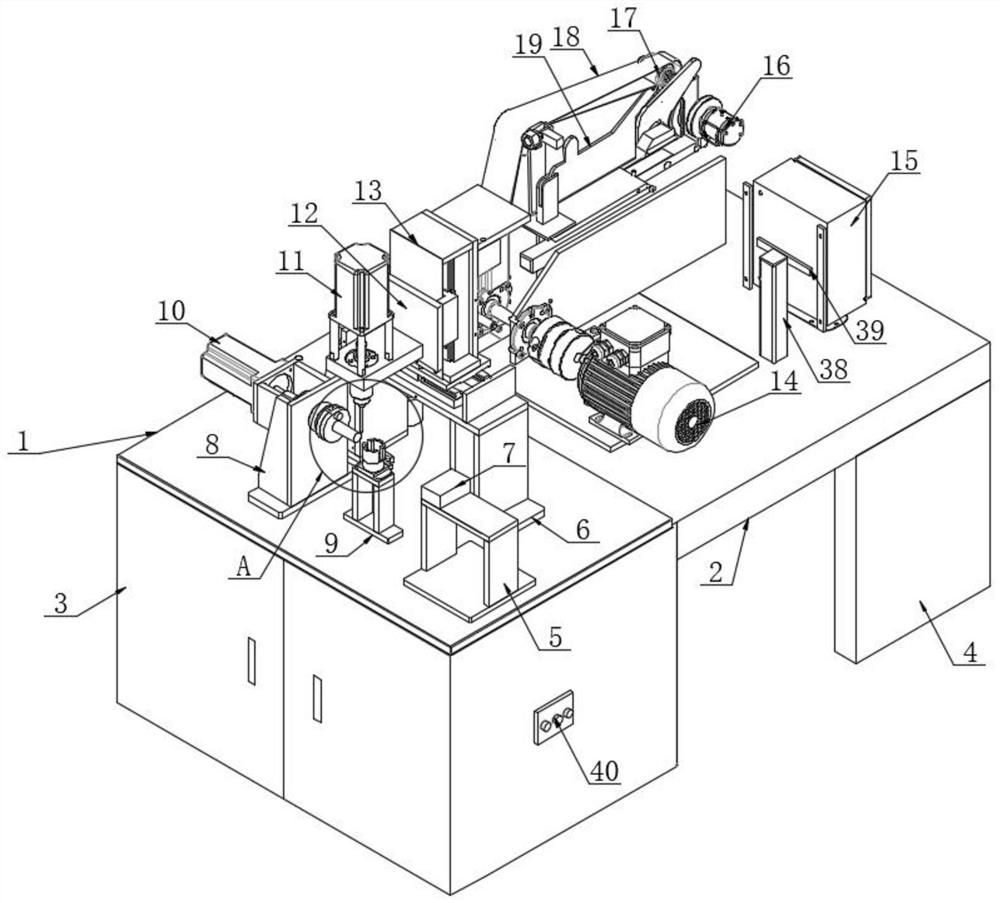

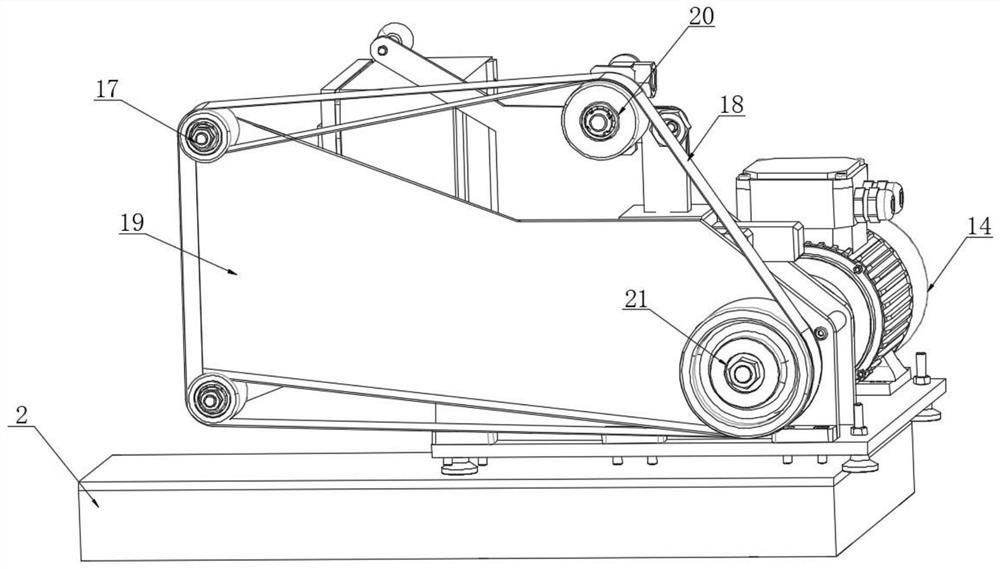

[0044] Such as Figure 1-Figure 10 As shown, an intelligent casting grinding device with a learning function according to an embodiment of the present invention includes: a box body 1, an abrasive belt grinding mechanism, a laser grinding mechanism, a debris collection mechanism and a control mechanism;

[0045] Wherein, the laser grinding mechanism is used for finely grinding the casting, and the laser grinding mechanism includes a first bracket 5, a second bracket 6, a third bracket 8 and two laser sensors 7, the first bracket 5, the second bracket 6 and the third bracket The brackets 8 are all fixedly connected to the top of the box body 1, the first bracket 5 and the third bracket 8 are oppositely arranged, and a first electric push rod 10 is installed on one side of the third bracket 8, and the piston rod of the first electric push rod 10 A first micro-motor 31 is installed, the rotating shaft of the first micro-motor 31 is fixedly connected with a first polishing rod 32,...

Embodiment 2

[0051] Such as Figure 1-Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the electric control terminals of the speed-adjusting motor 14, the servo motor 16, the first micro-motor 31, the rodless cylinder 12 and the second micro-motor 33 communicate with the single-chip microcomputer 36 through wires. electrical connection.

[0052] By adopting the above-mentioned technical solution, the single-chip microcomputer 36 can respectively control the startup and shutdown of the speed-regulating motor 14 , the servo motor 16 , the first micromotor 31 , the rodless cylinder 12 and the second micromotor 33 .

Embodiment 3

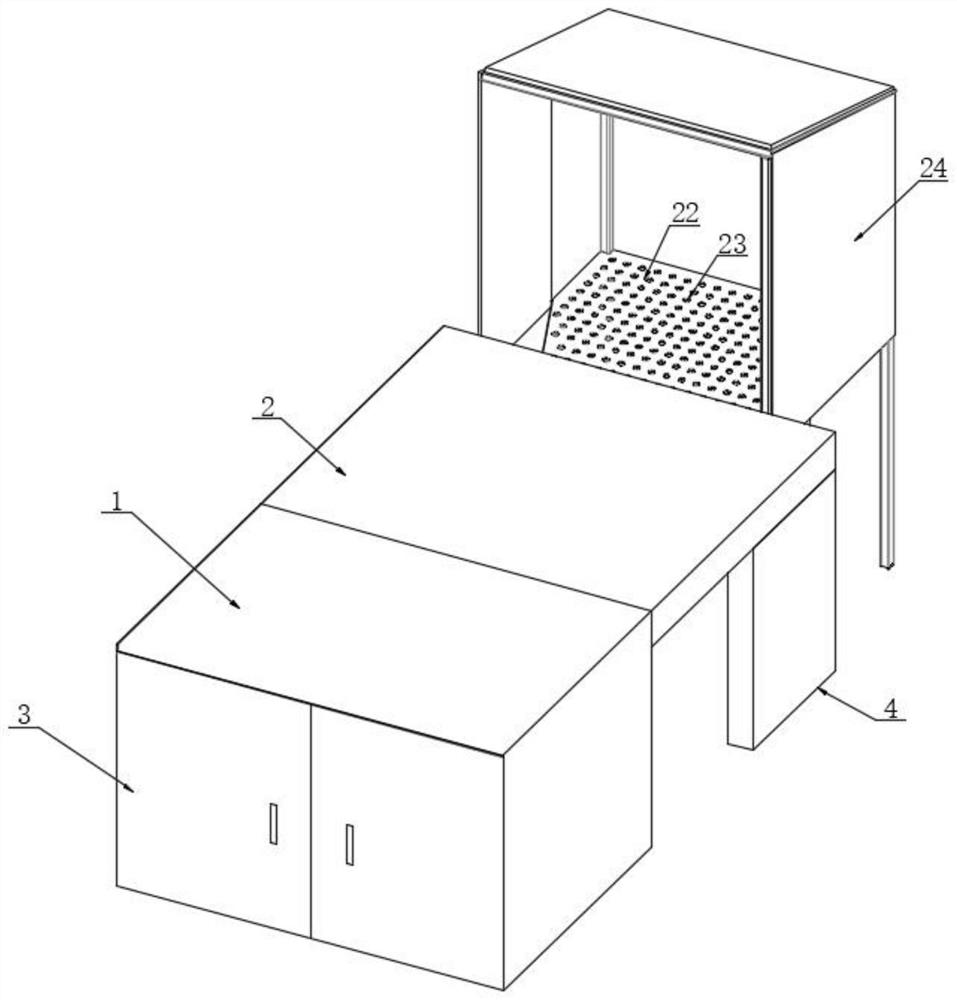

[0054] Such as Figure 1-Figure 3 As shown, the difference between this embodiment and Embodiment 2 is that the bottom of the support plate 2 is fixedly connected with the pillar 4 , and the bottom of the cover 24 is fixedly connected with the legs 27 .

[0055] By adopting the above technical solution, the pillar 4 can increase the bottom supporting force of the support plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com