Composite dental implant and preparation method thereof

A composite and implant technology, applied in dental implants, dentistry, prostheses, etc., can solve the problems of easy detachment of the surface antibacterial layer, limited biological activity of implants, and reduce the stress shielding effect, so as to improve the long-term antibacterial effect and Bone tissue regeneration, improving long-term stability and functionality, and solving the effect of bone tissue resorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

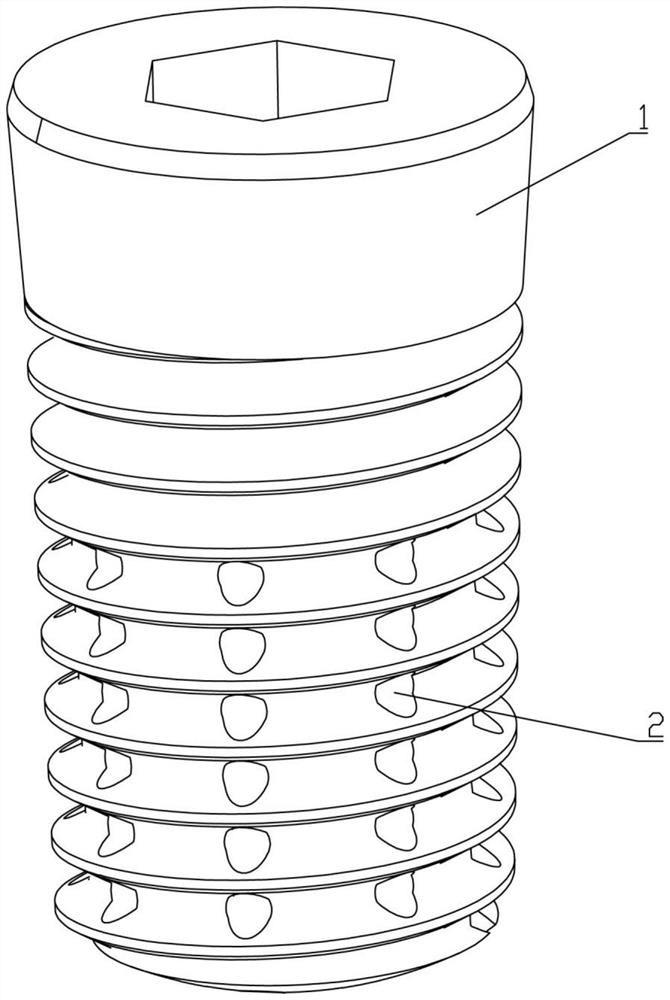

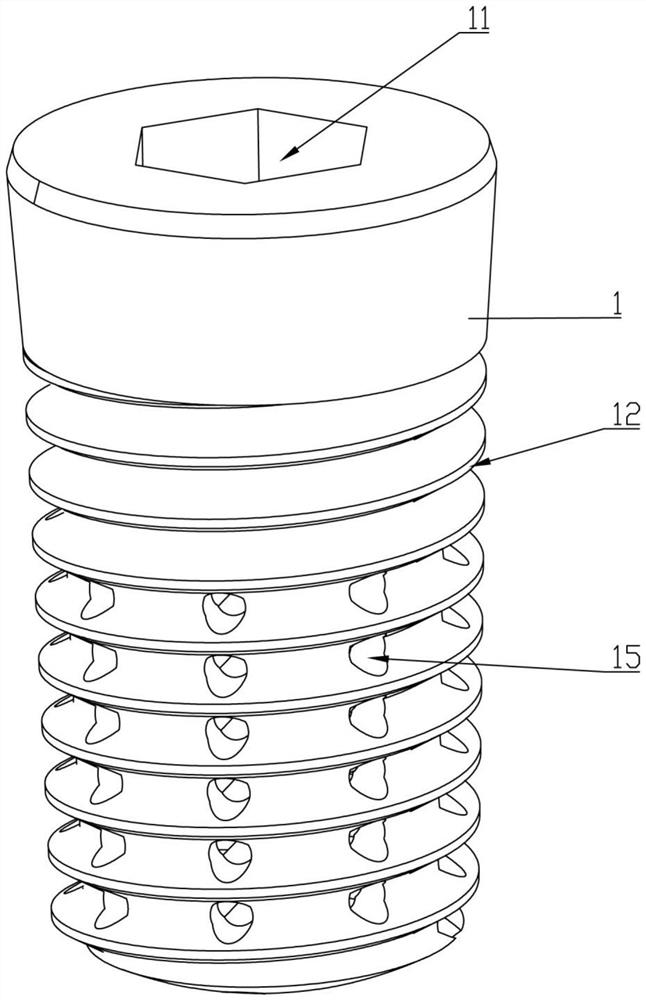

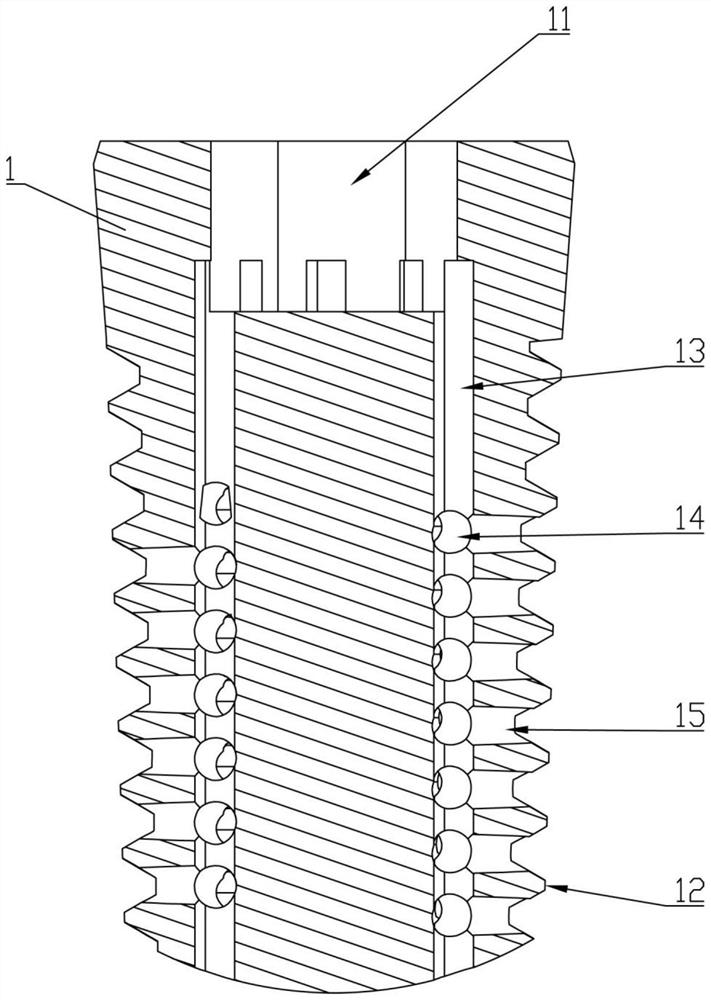

[0029] Such as Figure 1 to Figure 3 As shown, this embodiment provides a composite dental implant, including a body 1, a countersink hole 11 is opened on the top of the body 1, the bottom of the body 1 is arc-shaped, and an external thread 12 is provided on the outer periphery of the bottom end of the body 1. The body 1 is provided with a porous structure, and the porous structure is filled with a composite body 2, the composite body 2 is integrated with the body 1, and the composite body 2 is a biodegradable material loaded with bioactive ingredients, and the bioactive ingredients have antibacterial and bone tissue properties. Induces regeneration.

[0030] The porous structure includes a first hole body 13, a second hole body 14 and a third hole body 15. The first hole body 13 is opened along the axial direction of the body 1 and penetrates the body 1. The first hole body 13 communicates with the counterbore 11. The first hole body 13 is centered on the axis of the body 1,...

Embodiment 2

[0040] The difference from Embodiment 1 is that step 1: use general medical software to calculate the three-dimensional image of the patient's tooth root before operation, and analyze the data of the tooth-missing part to establish a three-dimensional model of the main body 1. After adjusting the optimization parameters, the diameter of the main body 1 is 2mm , the thread of the external thread 12 is 1000 μm, the hole shape of the counterbore 11 is a regular hexagonal hole, the equivalent pore diameter of the porous structure is 200 μm, and the hole shape of the porous structure is square; import the data into the SLM device, start the SLM device, and the SLM Under the protection of inert gas, the equipment completes the preparation of the main body 1, takes out and cleans the main body 1, cleans the main body 1 with acetone, ethanol and deionized water under ultrasonic waves, and puts it in the air at 37°C to dry it before use;

[0041] Step 2: In parts by weight, put 0.15-0.3...

Embodiment 3

[0046] The difference from Embodiment 1 is that step 1: use general medical software to calculate the three-dimensional image of the patient's tooth root before operation, and analyze the data of the tooth-missing part to establish a three-dimensional model of the main body 1. After adjusting the optimization parameters, the diameter of the main body 1 is 3.5 mm, the thread of the external thread 12 is 600 μm, the hole shape of the counterbore 11 is a regular hexagonal hole, the equivalent pore diameter of the porous structure is 250 μm, and the hole shape of the porous structure is a square; import the data into the SLM equipment, start the SLM equipment, Under the protection of the inert gas, the SLM equipment completes the preparation of the main body 1, takes out and cleans the main body 1, cleans the main body 1 with acetone, ethanol and deionized water under ultrasonic waves, and places it in air at 37°C to dry it before use;

[0047] Step 2: Dissolve cetyltrimethylammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com