Whitening essence suitable for long-term storage and preparation method thereof

A technology for long-term storage and essence, applied in the field of whitening essence and its preparation, can solve the problems of weakened whitening effect, easy oxidation and yellowing, etc., and achieve the effect of improving the stability of the formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

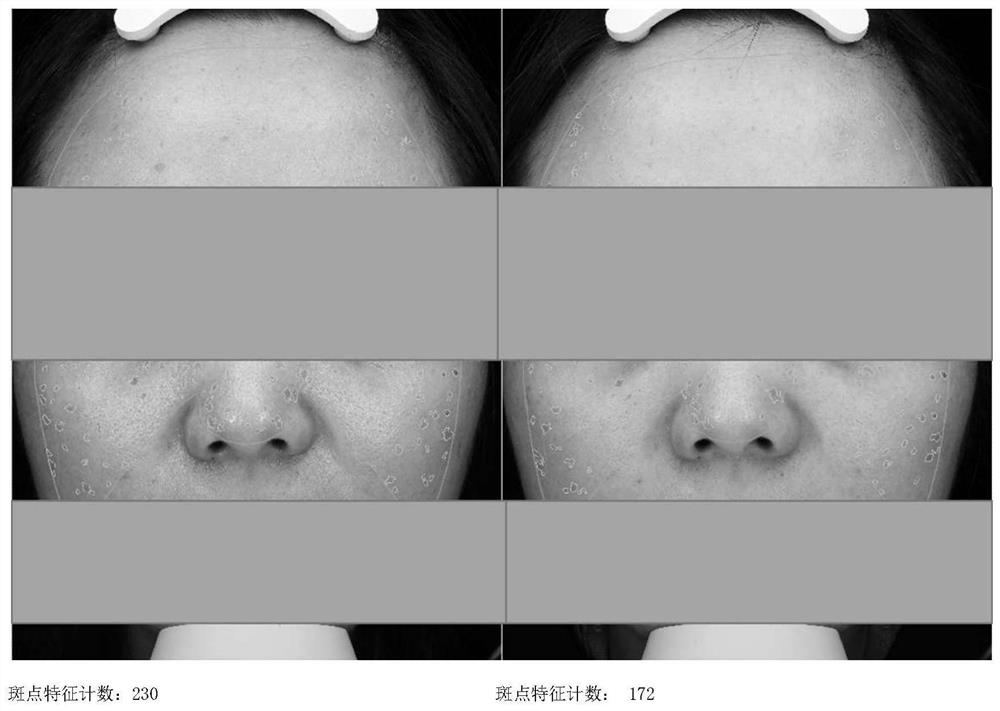

Image

Examples

Embodiment 1

[0099] This embodiment provides the preparation method of the above whitening essence. The specific ingredients are specifically shown in Table 1:

[0100] Table 1

[0101]

[0102]

[0103] The specific production process is as follows:

[0104] Step 1: Put the raw materials of group A into the container, stir and heat at 5-15rpm to 80-85°C, and keep warm for 5-10min; disperse acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer with polyol in advance, transparent Sodium hyaluronate, xanthan gum;

[0105] Step 2: Put the raw materials of group B into the container, homogenize at 400-1000rpm for 2-5min;

[0106] Step 3: Cool down to 45-60°C, put in group C raw materials, stir at 10-20rpm for 5-15min, and the preparation is complete.

[0107] In the raw materials of group C, the arginine is diluted in advance to an arginine aqueous solution with a mass ratio of 1:7-1:9.

[0108] Among the raw materials of group C, p-hydroxyacetophenone can be stirred and ...

Embodiment 2

[0113] Niacinamide 5%, Bifida yeast fermentation product lysate 0.5%, Adenosine 0.1%, Glycerin 6%, Butylene Glycol 1%, Polyethylene Glycol-81%, Panthenol 1%, Sodium Hyaluronate 0.02% , 1,2-Hexanediol 0.4%, Dimethicone (and) Dimethiconol 1%, Bis-PEG-18 Methyl Ether Dimethicone 0.5%, Acrylic (ester ) Class / C10-30 Alkyl Acrylate Crosspolymer 0.2%, Xanthan Gum 0.1%, Arginine 0.15%, Disodium EDTA 0.03%, Tocopheryl Acetate 0.2%, Para-Hydroxyacetophenone 0.4%, tris(tetramethylhydroxypiperidinol) citrate 0.02%, ascorbyl tetraisopalmitate 1%, deionized water 82.28%.

Embodiment 3

[0115] Niacinamide 0.5%, Bifida yeast fermentation product lysate 3%, Adenosine 0.01%, Glycerin 6%, Butylene Glycol 8%, Polyethylene Glycol-81.6%, Panthenol 0.5%, Sodium Hyaluronate 0.01% , 1,2-Hexanediol 0.4%, Dimethicone (and) Dimethiconol 2%, Bis-PEG-18 Methyl Ether Dimethicone 10%, Acrylic (ester ) Class / C10-30 Alkyl Acrylate Crosspolymer 0.3%, Xanthan Gum 0.15%, Arginine 0.22%, Disodium EDTA 0.1%, Tocopheryl Acetate 0.5%, Para-Hydroxyacetophenone 0.5%, tris(tetramethylhydroxypiperidinol) citrate 0.1%, ascorbyl tetraisopalmitate 0.1%, deionized water 71.46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com