Multi-stage shock absorption supporting device for mechanical equipment in complex environments

A technology for complex environments and mechanical equipment, applied in the direction of mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., to achieve the effect of increasing cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

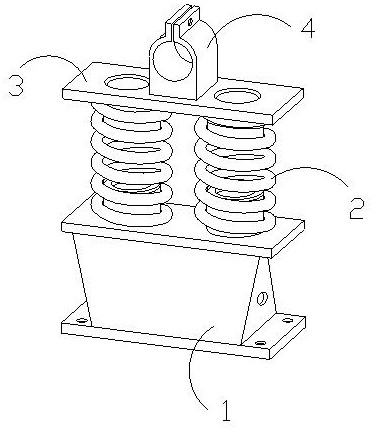

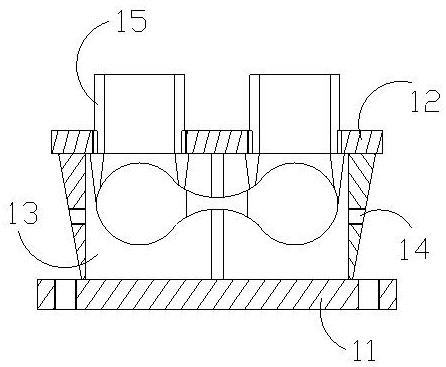

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032] The invention provides a multi-stage damping support device for complex environments of mechanical equipment, the structure of which is provided with a damping support 1, a spring 2, a connecting frame 3, and a locking frame 4, and the spring 2 is installed on the shock absorbing support 1 Above and movably matched, the connecting frame 3 is connected to the top end of the spring 2, and the locking frame 4 is embedded and installed in the middle of the top surface of the connecting frame 3.

[0033] The shock-absorbing support 1 is provided with a bottom plate 11, an upper plate 12, an inner groove 13, a side opening 14, and a through column 15. The bottom plate 11, the upper plate 12, and the inner groove 13 are integrated structures and are respectively located at the upper and lower ends thereof. Position, the through-pillar 15 and the upper plate 12 are an integral structure and are arranged through at the l...

Embodiment 2

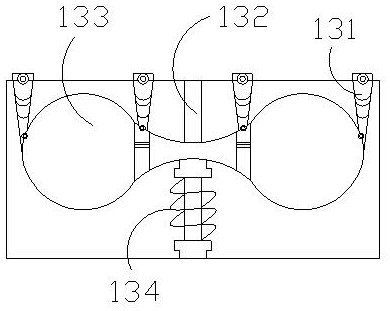

[0040] as attached Figure 7 to attach Figure 9 Shown:

[0041] Wherein, the moving body 134 is provided with a magnetic block c1, an outer winding spring c2, and a displacement block c3. The outer winding spring c2 is connected between the magnetic blocks c1, and the displacement block c3 is fixedly connected above the magnetic block c1. The displacement block c3 and the outer winding spring c2 are movable and coordinated through the magnetic block c1, and the middle sections of the magnetic block c1 and the displacement block c3 are in a transparent state, and the magnetic block c1 is provided with two, and they have the same The block of magnetic force generates a repelling magnetic field, and the displacement block c3 moves downward under the elastic cooperation of the outer winding spring c2 as the two ends are pulled. Down, it cooperates with the outer coil spring c2 to generate upward reverse thrust, which is convenient for the displacement block c3 to generate upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com