Weaving process of slightly-elastic crape

A technology of crepe cloth and craftsmanship, which is applied in the field of micro-elastic crepe cloth weaving technology, which can solve the problems of single appearance and environmental pollution of crepe cloth, and achieve the effect of good wrinkle effect and high comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

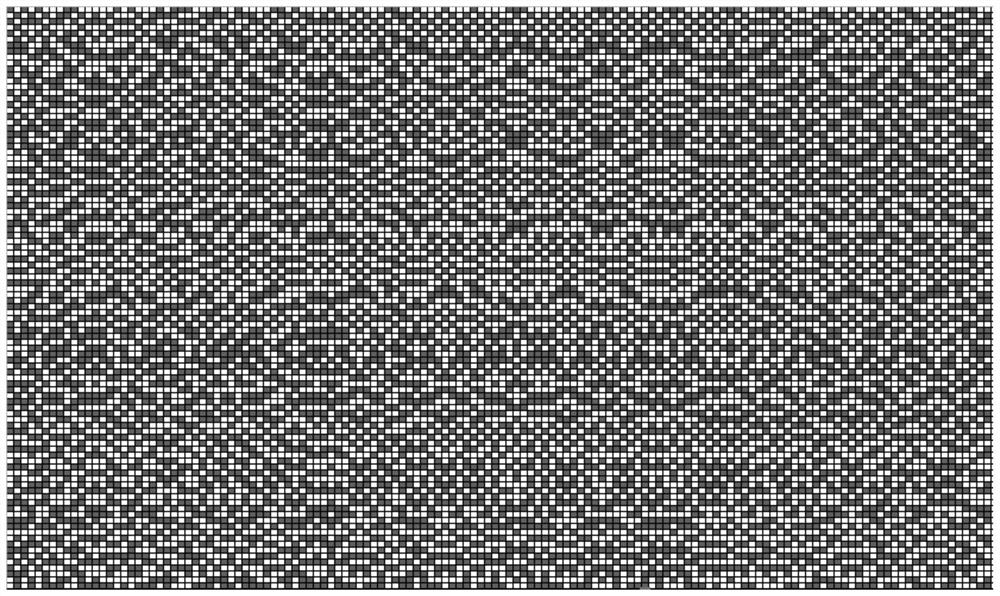

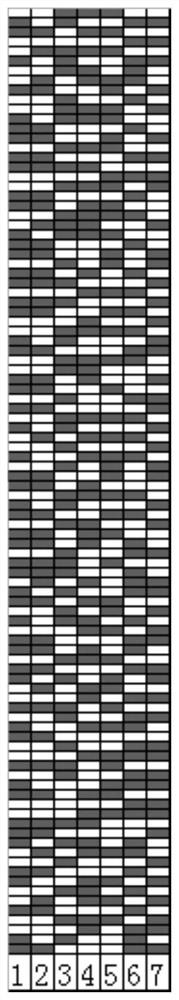

Image

Examples

Embodiment 1

[0023] A micro-elastic crepe weaving process, the concrete preparation process of crepe comprises the following steps:

[0024] (1) Warping process: use Benninger ZS98 warping machine to warp the warp yarns in batches, so that the warp yarns are tightly wound on the warp beams and wound into pulp beams, with 666 heads and 16 warp beams. The vehicle speed is 550m / min, the warping pressure is 0.4Mpa, the weight of the tension ring is 3g, and the tension is increased by 7g on each side;

[0025] (2) Sizing process: use Tsudakoma sizing machine for sizing treatment, single immersion double pressure sizing, sizing pressure force is 15KN, steam pressure is 0.55MPa, size tank temperature is 82°C, main cylinder temperature is 90°C, the viscosity of the slurry is 9s, the sizing speed is 55m / min, the sizing rate is 8%, and the moisture regain rate is 5%;

[0026] (3) Reeding process: use the threading method according to the drawing, and use the Stäubli automatic reeding machine, the d...

Embodiment 2

[0032] A micro-elastic crepe weaving process, the concrete preparation process of crepe comprises the following steps:

[0033] (1) Warping process: use Benninger ZS98 warping machine to warp the warp yarns in batches, so that the warp yarns are tightly wound on the warp beams and wound into pulp beams, with 666 heads and 16 warp beams. The vehicle speed is 550m / min, the warping pressure is 0.5Mpa, the weight of the tension ring is 3.5g, and the tension is increased by 9g on each side;

[0034] (2) Sizing process: use Tsudakoma sizing machine for sizing treatment, single immersion double pressure sizing, sizing pressure force is 15KN, steam pressure is 0.55MPa, size tank temperature is 82°C, main cylinder temperature is 90°C, the viscosity of the slurry is 9s, the sizing speed is 55m / min, the sizing rate is 10%, and the moisture regain rate is 6%;

[0035] (3) Reeding process: use the threading method according to the drawing, and use the Stäubli automatic reeding machine, th...

Embodiment 3

[0041] A micro-elastic crepe weaving process, the concrete preparation process of crepe comprises the following steps:

[0042] (1) Warping process: use Benninger ZS98 warping machine to warp the warp yarns in batches, so that the warp yarns are tightly wound on the warp beams and wound into pulp beams, with 666 heads and 16 warp beams. The vehicle speed is 550m / min, the warping pressure is 0.45Mpa, the weight of the tension ring is 3.2g, and the tension is increased by 8g on each side;

[0043] (2) Sizing process: use Tsudakoma sizing machine for sizing treatment, single immersion double pressure sizing, sizing pressure force is 15KN, steam pressure is 0.55MPa, size tank temperature is 82°C, main cylinder temperature is At 90°C, the slurry viscosity is 9s, the sizing speed is 55m / min, the sizing rate is 9%, and the moisture regain rate is 5.5%;

[0044] (3) Reeding process: use the threading method according to the drawing, and use the Stäubli automatic reeding machine, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com