Skip-plating-free pre-coating hot-forming steel plate with low crack sensitivity and manufacturing method

A manufacturing method and sensitive technology, applied in the direction of coating, hot dip plating process, metal material coating process, etc., to achieve the effect of strong fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

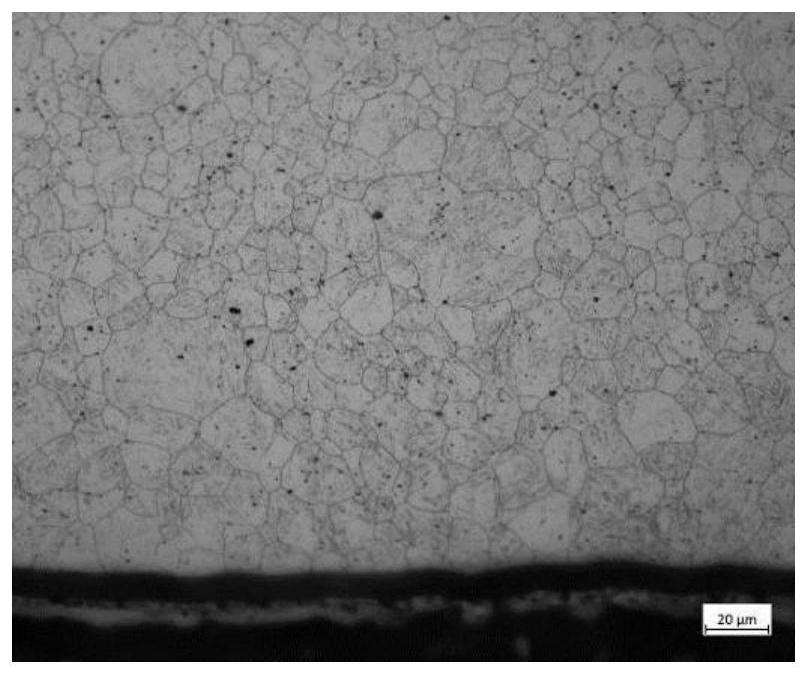

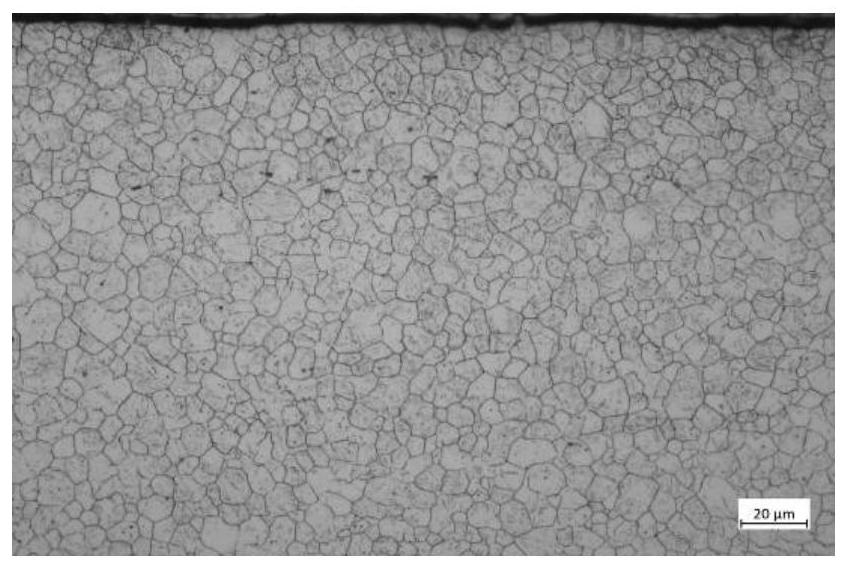

[0057] A non-spill-coated pre-coated hot-formed steel sheet with low crack sensitivity in this embodiment, the base steel sheet contains the following components in terms of mass percentage: C: 0.10-0.36%, Si: ≤0.5%, Mn: 0.5 -1.5%, P: ≤0.020%, S: ≤0.010%, Cr: ≤0.50%, Al: 0.01-0.06%, Nb+V+Ti≤0.15%, Mo: ≤0.5%, the rest is Fe and unavoidable impurities, by adjusting the C content of the matrix, a sufficiently high peak force of cold bending can be obtained under a certain thickness of the decarburized layer; during cold bending, when the peak force of cold bending is reached, the slope between the cold bending force and the displacement As the thickness of the decarburization layer changes, that is, the thickness of the decarburization layer will have a certain impact on the crack growth. The slower the crack growth rate, the stronger the fracture resistance of the material.

[0058] Further, more than one of the three elements in the Nb, V, and Ti are combined, and the effect of...

Embodiment 2

[0060] A non-spill-coated pre-coated hot-formed steel sheet with low crack sensitivity in this embodiment has the same basic structure as that of Embodiment 1, the difference and improvement are: for the 1500MPa strength level, the base steel sheet contains The following components are: C: 0.23-0.24%, Si: ≤0.5%, Mn: 1.2-1.3%, P: ≤0.020%, S: ≤0.010%, Cr: ≤0.50%, Al: 0.01-0.06%, Nb +V+Ti≤0.15%, B: 0.002%~0.005%, the rest is Fe and unavoidable impurities.

[0061] Further, two or more of the three elements of Nb, V and Ti are combined, and the Ti: 0.015-0.035%.

Embodiment 3

[0063] A non-spill-coated pre-coated hot-formed steel sheet with low crack sensitivity in this embodiment has the same basic structure as that of Embodiment 2, the difference and improvement are: for the 1800MPa strength level, the base steel sheet contains The following components are: C: 0.33-0.36%, Si: ≤0.5%, Mn: 1.2-1.3%, P: ≤0.020%, S: ≤0.010%, Cr: ≤0.50%, Al: 0.01-0.06%, Nb +V+Ti≤0.15%, Mo:≤0.5%, the rest is Fe and unavoidable impurities.

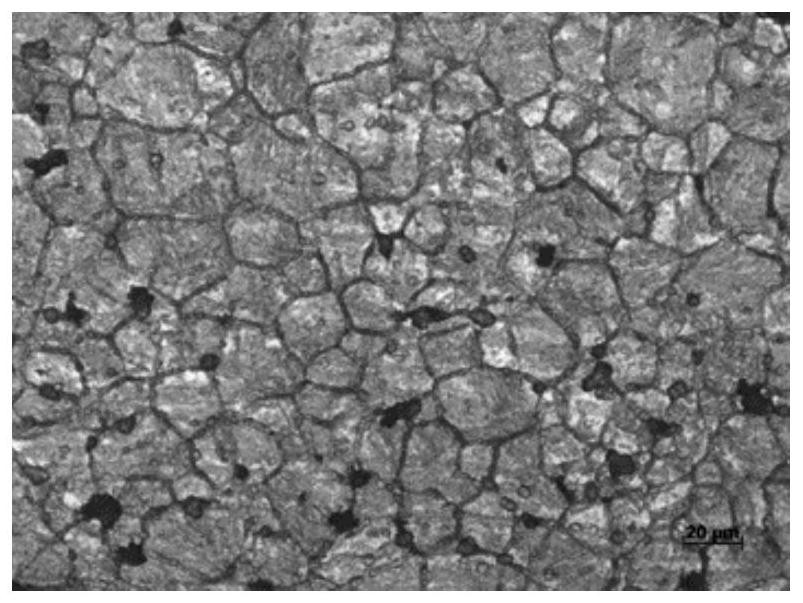

[0064] Further, such as figure 1 , 2 , 4, more than one of the three elements of Nb, V, and Ti are combined, the Nb: 0.03% to 0.05%, when the Nb content is less than 0.03%, it is easy to cause the grain refinement effect is not obvious ; When the Nb content is greater than 0.05%, it will cause unnecessary waste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com