Negative ion negative potential organic selenium nutrient solution and preparation method and application thereof

A technology of organic selenium and negative potential, applied in application, organic fertilizer, fertilization methods, etc., can solve the problems of low absorption efficiency of organic selenium fertilizer, liquid fertilizer drops are not easy to penetrate, liquid fertilizer slips down, etc., to improve quality and flavor, maintain The effect of biological yin and yang balance and improving fertilizer absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

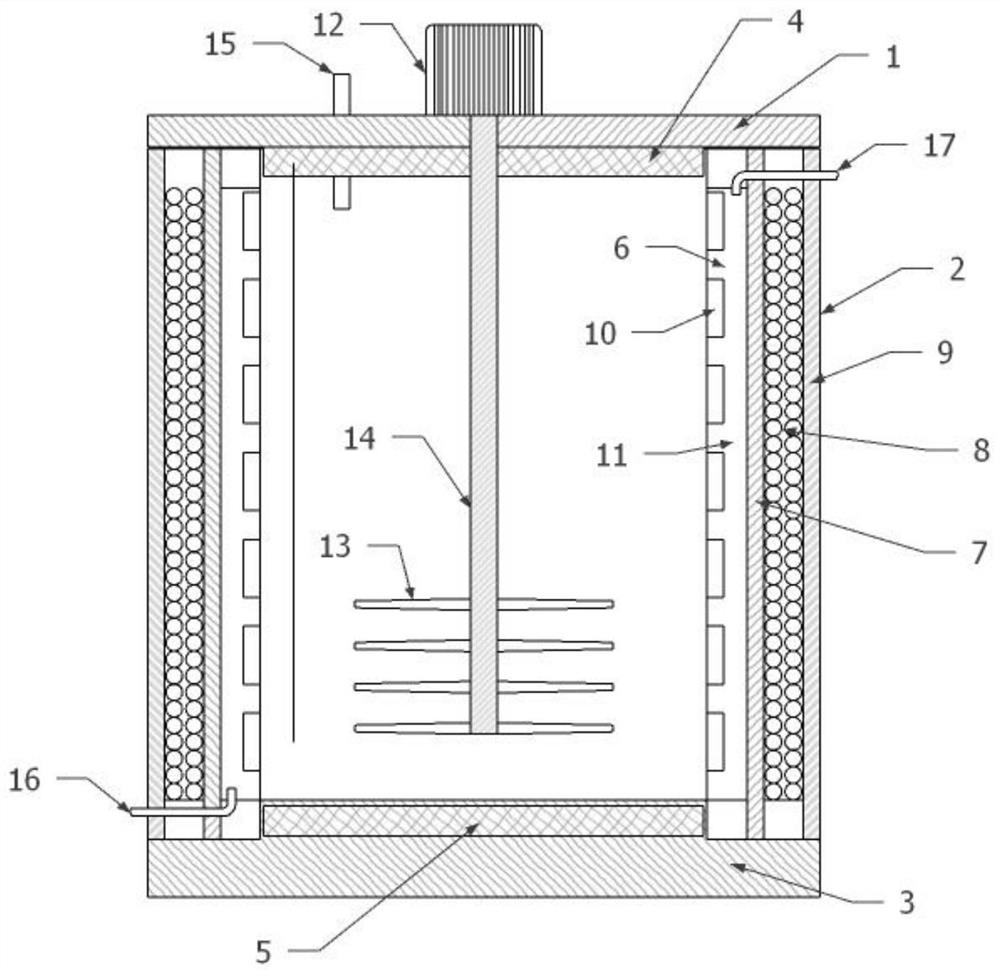

Method used

Image

Examples

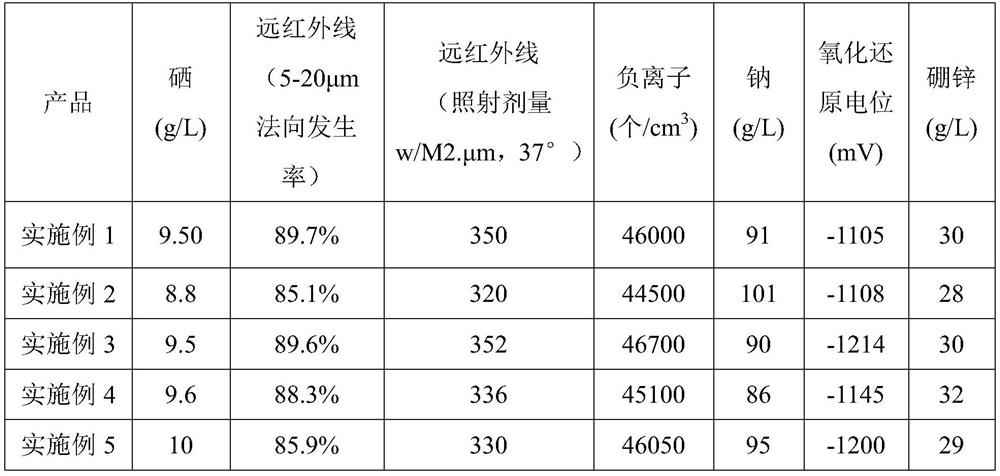

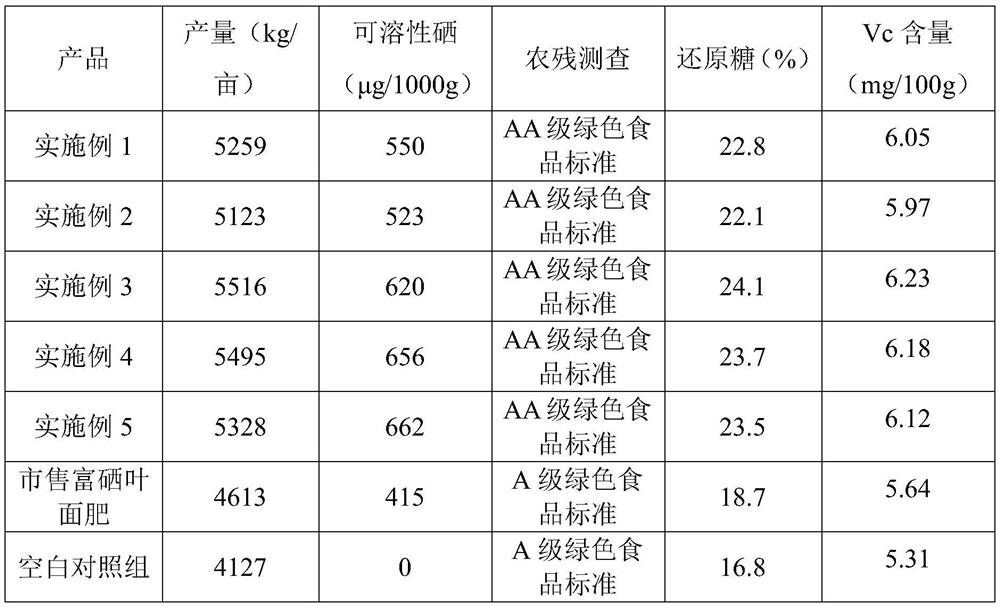

Embodiment 1

[0029] An anion and negative potential organic selenium nutrient solution, comprising the following raw materials in parts by weight: 50 parts of sodium carbonate, 5 parts of potassium hydroxide, 160 parts of sodium silicate, 78 parts of borax, 40 parts of sugar, 60 parts of organic selenium, 20 parts of infrared tourmaline, 50 parts of zinc sulfate, 12 parts of potassium carbonate, and 550 parts of water.

[0030] The present embodiment also provides the preparation method of negative ion negative potential organic selenium nutrient solution, comprising the following steps:

[0031] (1) Mix 400 parts of water, 50 parts of sodium carbonate, 5 parts of potassium hydroxide, 160 parts of sodium silicate, 78 parts of borax, 40 parts of sugar, 50 parts of zinc sulfate, and 12 parts of potassium carbonate, heat up to 125°C, and stir Reacted for 3h to obtain mixed solution A;

[0032] (2) Add 60 parts of organic selenium, 20 parts of far-infrared tourmaline and 150 parts of water in...

Embodiment 2

[0039] An anion and negative potential organic selenium nutrient solution, comprising the following raw materials in parts by weight: 50 parts of sodium carbonate, 10 parts of potassium hydroxide, 200 parts of sodium silicate, 60 parts of borax, 30 parts of sugar, 50 parts of organic selenium, 17 parts of infrared tourmaline, 55 parts of zinc sulfate, 10 parts of potassium carbonate, and 600 parts of water.

[0040] The present embodiment also provides the preparation method of negative ion negative potential organic selenium nutrient solution, comprising the following steps:

[0041] (1) Heat 500 parts of water, 50 parts of sodium carbonate, 10 parts of potassium hydroxide, 200 parts of sodium silicate, 60 parts of borax, 30 parts of sugar, 55 parts of zinc sulfate and 10 parts of potassium carbonate, heat up to 130°C, and stir to react 2h, to obtain the mixed solution A;

[0042] (2) Add 50 parts of organic selenium, 17 parts of far-infrared tourmaline and 100 parts of wate...

Embodiment 3

[0045] An anion and negative potential organic selenium nutrient solution, comprising the following raw materials in parts by weight: 50 parts of sodium carbonate, 5 parts of potassium hydroxide, 160 parts of sodium silicate, 78 parts of borax, 40 parts of sugar, 60 parts of organic selenium, 20 parts of infrared tourmaline, 50 parts of zinc sulfate, 12 parts of potassium carbonate, 550 parts of water, 9 parts of dioctyl sodium sulfosuccinate, 2 parts of cocoyl glucoside, 3 parts of cocoic acid diethanolamide.

[0046] The present embodiment also provides the preparation method of negative ion negative potential organic selenium nutrient solution, comprising the following steps:

[0047] (1) Mix 400 parts of water, 50 parts of sodium carbonate, 5 parts of potassium hydroxide, 160 parts of sodium silicate, 78 parts of borax, 40 parts of sugar, 50 parts of zinc sulfate, and 12 parts of potassium carbonate, heat up to 125°C, and stir Reacted for 3h to obtain mixed solution A;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com