Aloe lysozyme gel rich in pleurotus djamor fruiting body polypeptide and preparation method of aloe lysozyme gel

A technology of red oyster mushroom seeds and lysozyme, which is applied in the development of cosmetics and edible fungus resources, can solve the problems of insufficient natural moisturizing ingredients, insufficient antioxidant effect, and weak antioxidant effect, so as to improve the effect of scavenging free radicals and delay skin aging , good antioxidant capacity and antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

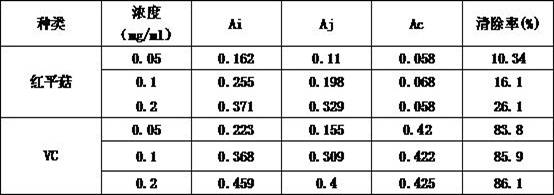

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of red oyster mushroom polypeptide powder

[0038] Select the fresh oyster mushroom fruiting body cultivated in the greenhouse, dry it by blowing air for 12 hours at a temperature of 60°C, and then crush it into oyster mushroom powder with a particle size of less than 75 μm; weigh 100 parts by weight of oyster mushroom powder Add to 1000 parts by weight of pH 8.0 dilute sodium hydroxide solution, mix well, then add 10 parts by weight of alkaline protease and stir for enzymolysis, enzymolysis temperature is 55°C, stirring speed is 60rpm, enzymolysis After 5 hours, filter to remove impurities to obtain a filtrate; add 4 times the volume of absolute ethanol to the filtrate, precipitate at 4°C for 12 hours, and refrigerate and centrifuge at 5000g for 20 minutes to remove soluble sugars and take the supernatant. The supernatant was concentrated 10 times by rotary evaporation at 55°C at a speed of 40rpm, and the concentrated solution was frozen i...

Embodiment 2

[0039] Embodiment 2: the preparation of red oyster mushroom polypeptide powder

[0040] Select the fresh oyster mushroom fruiting body cultivated in the greenhouse, dry it by blowing air for 12 hours at a temperature of 60°C, and then crush it into oyster oyster mushroom powder with a particle size of less than 38 μm; weigh 150 parts by weight of oyster oyster mushroom powder Add to 1000 parts by weight of pH 8.0 dilute sodium hydroxide solution, mix well, then add 10 parts by weight of alkaline protease and stir for enzymolysis, enzymolysis temperature is 55°C, stirring speed is 60rpm, enzymolysis After 6 hours, filter to remove impurities to obtain a filtrate; add 4 times the volume of absolute ethanol to the filtrate, precipitate at 4°C for 12 hours, refrigerate and centrifuge at 5000g for 20 minutes, remove soluble sugar, and take the supernatant. The supernatant was concentrated 10 times by rotary evaporation at 55°C at a speed of 40rpm, and the concentrated solution was fr...

Embodiment 3

[0041] Embodiment 3: the preparation that is rich in the aloe lysozyme gel of oyster mushroom polypeptide powder

[0042] 1. Formula: The number of parts of each component in the aloe gel is 1 part of aloe powder, 2 parts of red oyster mushroom polypeptide powder, 0.5 part of enzyme-cut oligomeric sodium hyaluronate, 1 part of α-arbutin, Schizophyllan 35 parts, lactobionic acid 10 parts, glycosyl trehalose 15 parts, acrylic acid (ester) / C10-30 alkanol acrylate crosspolymer 8 parts, hydroxyacetophenone 6 parts, 1,2 hexyl 6 parts of glycol, 30 parts of 1,3 propylene glycol, 40 parts of glycerin, 4 parts of aminomethyl propanol and 100 parts of deionized water.

[0043] 2. Preparation

[0044] According to the above formula, put deionized water into the vacuum emulsification mixer unit, and put the pre-swelled acrylic acid (ester) type / C10-30 alkanol acrylate crosslinked polymer into the vacuum emulsification mixer unit, start stirring and heating up, Stirring speed is 40rpm / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com