Production process for increasing continuous casting heats of aluminum deoxidized high-carbon chromium bearing steel

An aluminum deoxidized high-carbon chromium bearing and a production process technology, applied in the field of iron and steel metallurgy, can solve the problems of poor castability of bearing steel and unqualified water immersion flaw detection, so as to increase the number of continuous casting furnaces and solve the problem of unqualified water immersion flaw detection , reduce the effect of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The test steel is high-carbon chromium bearing steel, the grade is GCr15, and the production process is "converter / electric furnace—LF refining—RH vacuum treatment—billet continuous casting":

[0022] (1) During the tapping process, aluminum particles are added for deoxidation at one time, and the aluminum content in the steel is required to be added to 0.03-0.06%. At the same time, low-titanium and low-aluminum ferrosilicon is added, and the Si content in the steel is required to reach 0.10%-0.16%, before LF treatment. slag or slag removal;

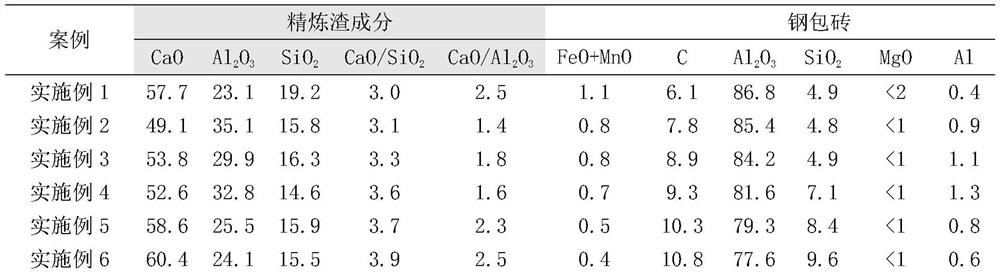

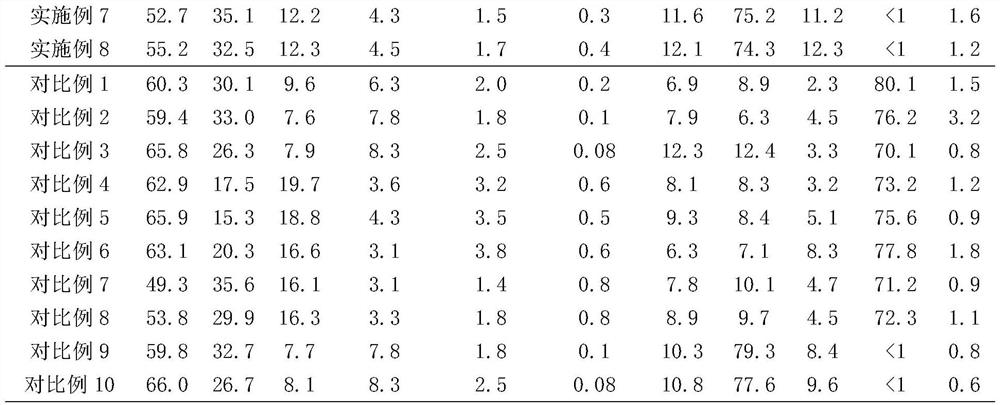

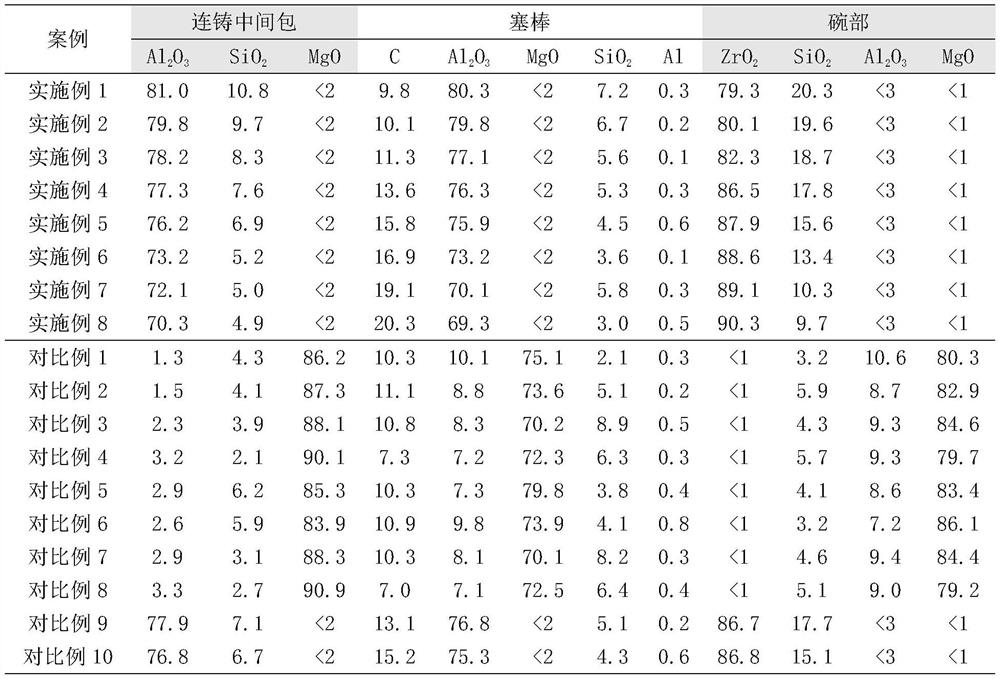

[0023] (2) Add lime, quartz sand or CaO-Al to LF refining slag 2 o 3 It is one or several kinds of pre-melted slag, and it is required to ensure the final slag basicity of LF refining slag CaO / SiO 2 Control range 3.0~4.5, final slag CaO / Al 2 o 3 The control range is 1.3~2.5, the amount of refining slag added is 8~10kg / t, and the final slag is required to be 0.3%<FeO+MnO<1.0%, and it is strictly forbidden to add aluminum partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com