Preparation of matrix-free long-afterglow carbon dots, adjustment and control method of afterglow types and application thereof

A long-lasting, matrix-free technology, applied in the field of materials, can solve the problems of difficult realization of CDs, limit the application of long-lasting CDs, complex environmental toxicity in the preparation process, etc., and achieve delayed fluorescence and room temperature phosphorescence, long afterglow life, and cheap and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 1.0 g of benzoic acid derivative and 500 μL of ethylenediamine solution into 10 mL of ultrapure water, then transfer the above solution to a 50 mL autoclave lined with Teflon, and heat at 200 °C for 12 hours After cooling to room temperature, the CDs solution was obtained and stored in a refrigerator at 4°C.

[0035] 2) Treat the CDs solution obtained in step 1) with a 0.22 μm filter membrane to remove large particles;

[0036] 3) The CDs solution obtained in step 2) is vacuum freeze-dried to obtain solid long-lasting CDs powder, which is stored in a desiccator.

[0037] In said step 1), benzoic acid derivatives are respectively selected from phthalic acid (prepared product is denoted as Pht-CDs), isophthalic acid (prepared product is denoted as Iso-CDs), terephthalic acid (prepared product is denoted as Iso-CDs), terephthalic acid (prepared product The product is denoted as Ter-CDs), diphthalic acid (the product prepared is denoted as Hem-CDs), trimellitic ac...

Embodiment 2

[0039] 1) Weigh 1.0g of benzoic acid derivative and 500μL of ethylenediamine solution into 10mL of ultrapure water, then transfer the above solution to a 50mL autoclave lined with polytetrafluoroethylene, and heat at 200°C for 12h , cooled to room temperature to obtain a CDs solution, and stored in a refrigerator at 4°C.

[0040] 2) Treat the CDs solution obtained in step 1) with a 0.22 μm filter membrane to remove large particles;

[0041] 3) The CDs solution obtained in step 2) is vacuum freeze-dried to obtain solid long-lasting CDs powder, which is stored in a desiccator.

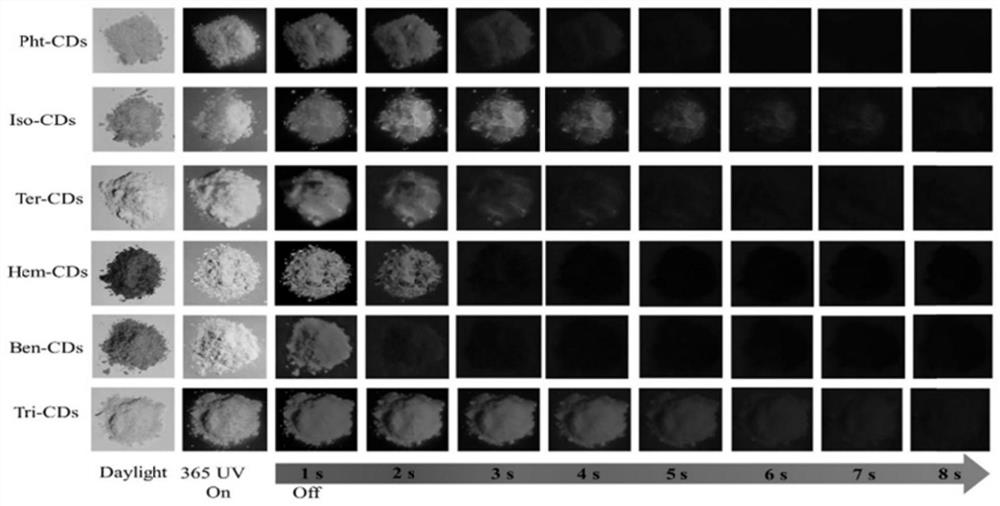

[0042] 4) The CDs powder prepared in step 3) is used for information anti-counterfeiting and encryption.

[0043] In the step 1), benzoic acid derivatives are respectively selected from phthalic acid, isophthalic acid, terephthalic acid, phthalic acid, trimellitic acid, and trimellitic acid to prepare CDs respectively.

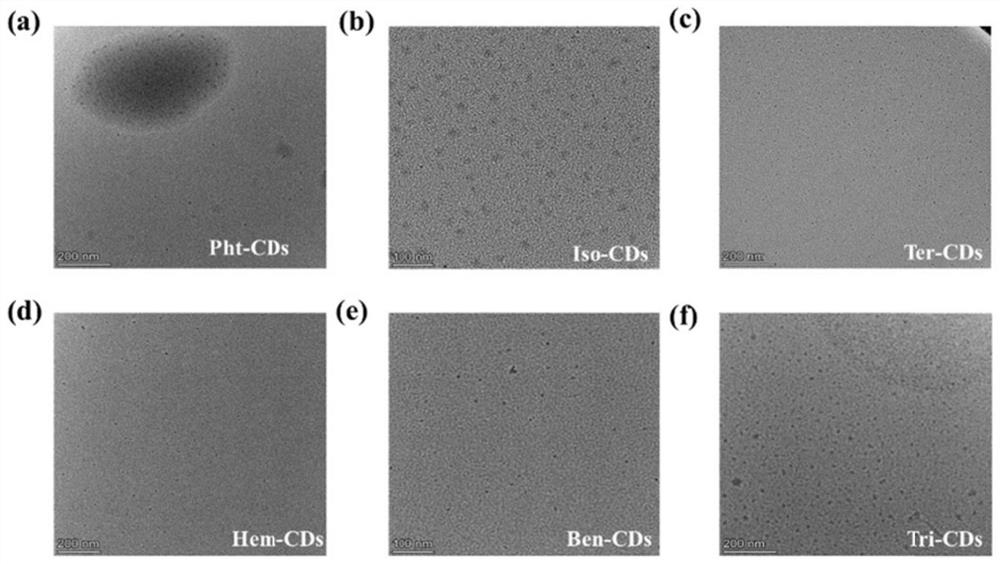

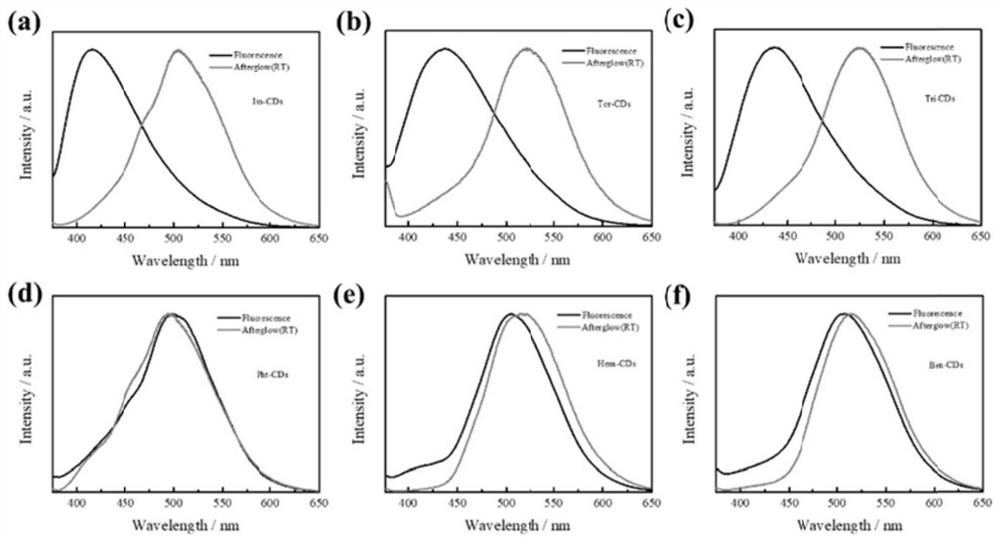

[0044] figure 1 TEM images of the six kinds of CDs prepared in the examples, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com