Novel-phase two-dimensional galena silver telluride synthesized on basis of two-dimensional tellurium template method and preparation method and application of novel-phase two-dimensional galena silver telluride

A template method, galena technology, applied in the direction of binary selenium/tellurium compounds, metal selenide/telluride, etc., can solve the problems of by-products, difficult to control product morphology, crystallinity and stoichiometric ratio, etc., to achieve High crystallinity, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

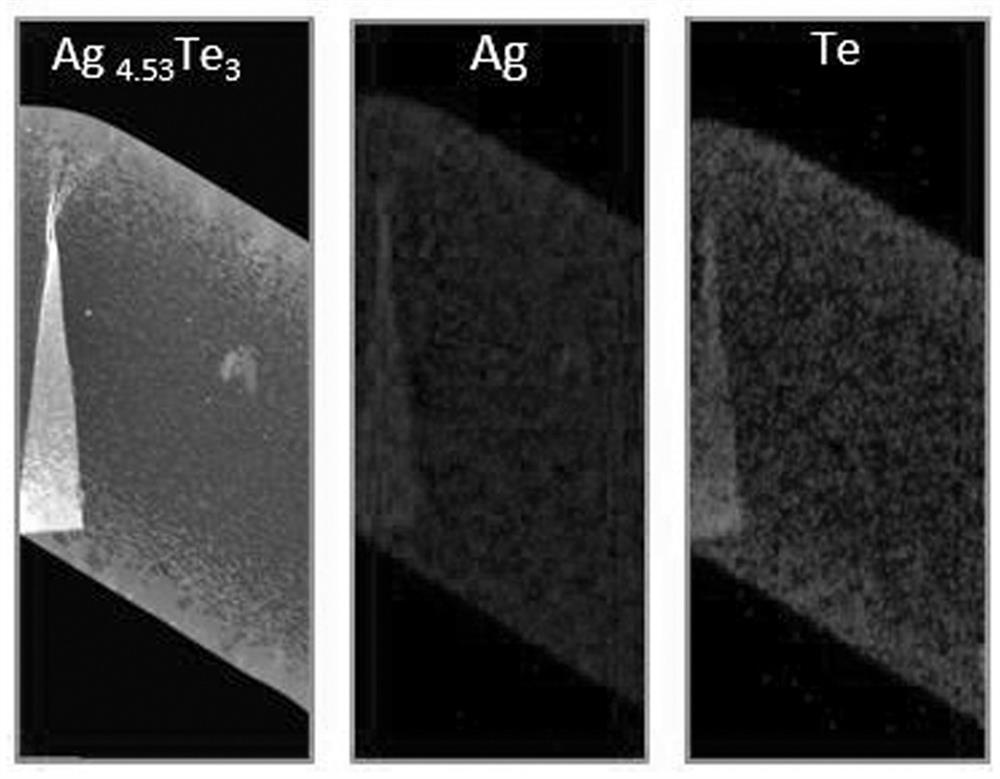

Image

Examples

Embodiment 1

[0030] S1: Dissolve 0.1 g of sodium tellurite and 0.5 g of polyvinylpyrrolidone with a molecular weight of 58,000 in 30 mL of deionized water with a conductivity of 18.2 MΩ cm, and stir for 30 minutes under a magnetic stirrer to form a concentration of 0.015 mol / L Solution A, then mixed 1.65mL hydrazine hydrate and 3.3mL ammonia water to form solution B, added to solution A, put into a hydrothermal reaction kettle, sealed and reacted in a 180-degree oven for 36 hours to obtain product C.

[0031] S2: Centrifuge the product C at a speed of 5000rpm for 10 minutes to remove the upper layer solution, then add acetone and deionized water with a conductivity of 18.2MΩ cm to the centrifuge tube and wash it repeatedly three times to obtain a silver-gray two-dimensional tellurium Solution D of nanosheet crystals.

[0032] S3: Dissolve silver nitrate in deionized water with a conductivity of 18.2MΩ•cm to obtain a silver nitrate solution with a concentration of 1mg / mL, add 3mL of silver ...

Embodiment 2

[0034] S1: Dissolve 0.1 g of sodium tellurite and 0.5 g of polyvinylpyrrolidone with a molecular weight of 58,000 in 33 mL of deionized water with a conductivity of 18.2 MΩ cm, and stir for 30 minutes under a magnetic stirrer to form a concentration of 0.014 mol / Solution A of L, then mixed 1.65mL hydrazine hydrate and 3.3mL ammonia water to form solution B, added to solution A, and put into a hydrothermal reaction kettle, sealed and reacted in a 160-degree oven for 34 hours to obtain product C.

[0035] S2: Centrifuge the product C at 4500rpm for 10 minutes to remove the upper layer solution, then add acetone and deionized water with a conductivity of 18.2MΩ cm to the centrifuge tube and wash it repeatedly three times to obtain a silver-gray two-dimensional tellurium Solution D of nanosheet crystals.

[0036] S3: Dissolve silver nitrate in deionized water with a conductivity of 18.2 MΩ·cm to obtain a silver nitrate solution with a concentration of 2.5 mg / mL, add 5 mL of silve...

Embodiment 3

[0045] S1: Dissolve 0.1 g of sodium tellurite and 0.5 g of polyvinylpyrrolidone with a molecular weight of 58,000 in 28 mL of deionized water with a conductivity of 18.2 MΩ cm, and stir for 30 minutes under a magnetic stirrer to form a concentration of 0.016 mol / L solution A, then mixed 1.65mL hydrazine hydrate and 3.3mL ammonia water to form solution B, added it to solution A, put it into a hydrothermal reaction kettle, sealed it, and reacted it in a 165 degree oven for 32 hours to obtain product C.

[0046] S2: Centrifuge the product C at 4000rpm for 10 minutes to remove the upper layer solution, then add acetone and deionized water with a conductivity of 18.2MΩ cm to the centrifuge tube and wash it repeatedly three times to obtain a silver-gray two-dimensional tellurium Solution D of nanosheet crystals.

[0047] S3: Dissolve silver nitrate in deionized water with a conductivity of 18.2 MΩ·cm to obtain a silver nitrate solution with a concentration of 7.5 mg / mL, add 3 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com