System for controlling temperature of plastic part by injection mold

A technology for injection molds and plastic parts, applied in the field of injection mold production equipment, can solve the problems of hidden safety hazards for operators, cracks, troublesome processing, etc., and achieve the effects of avoiding safety hazards, rapid cooling, and avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

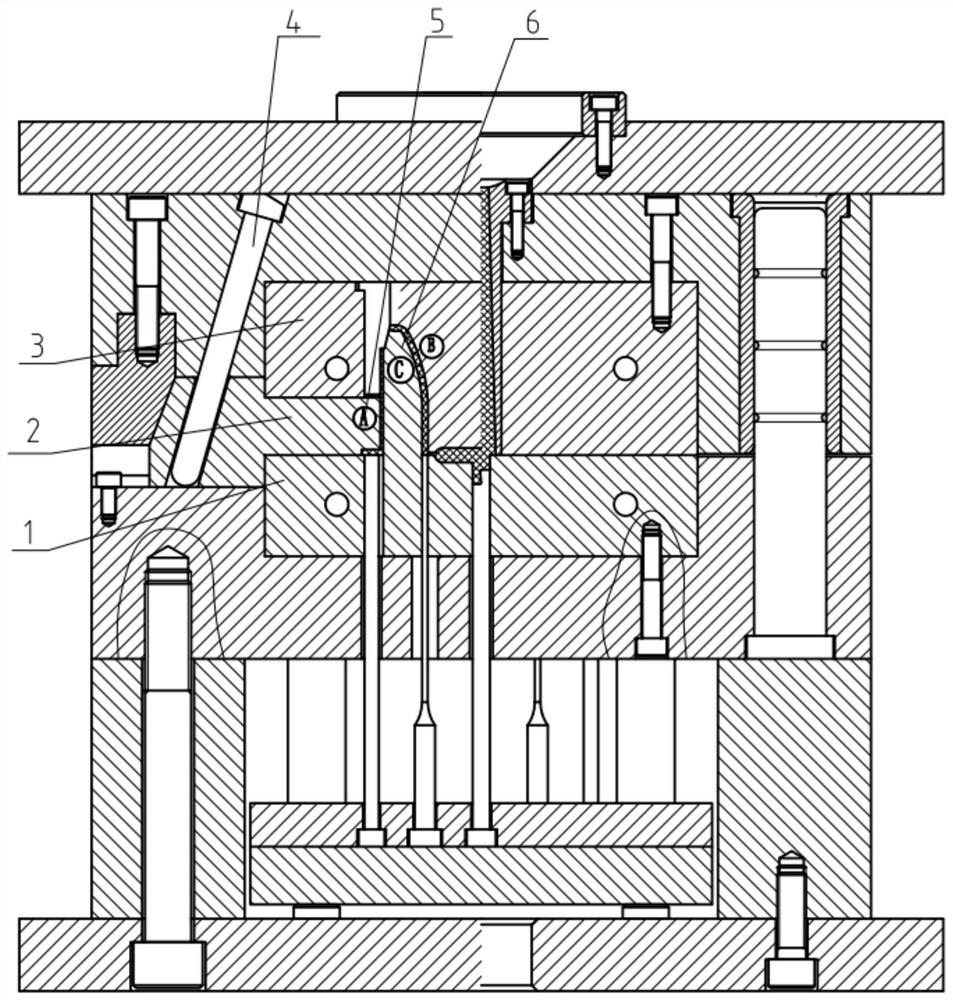

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

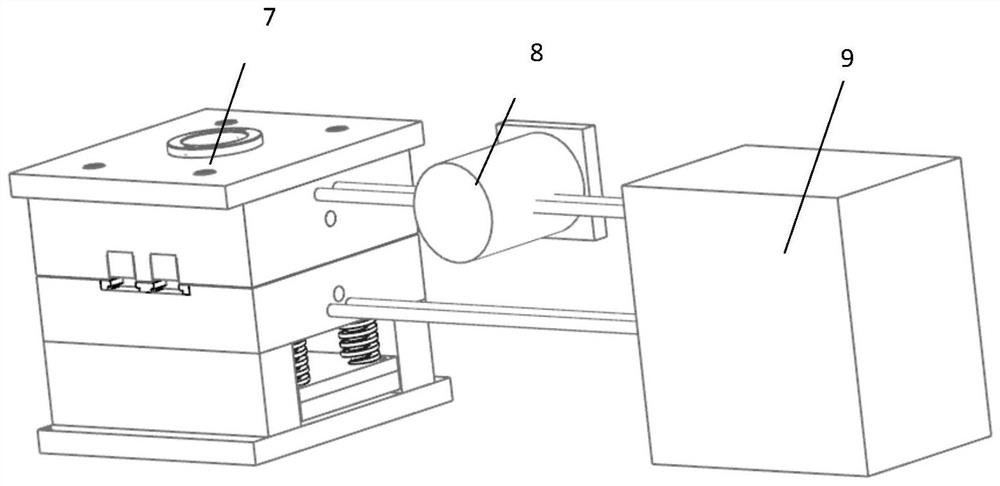

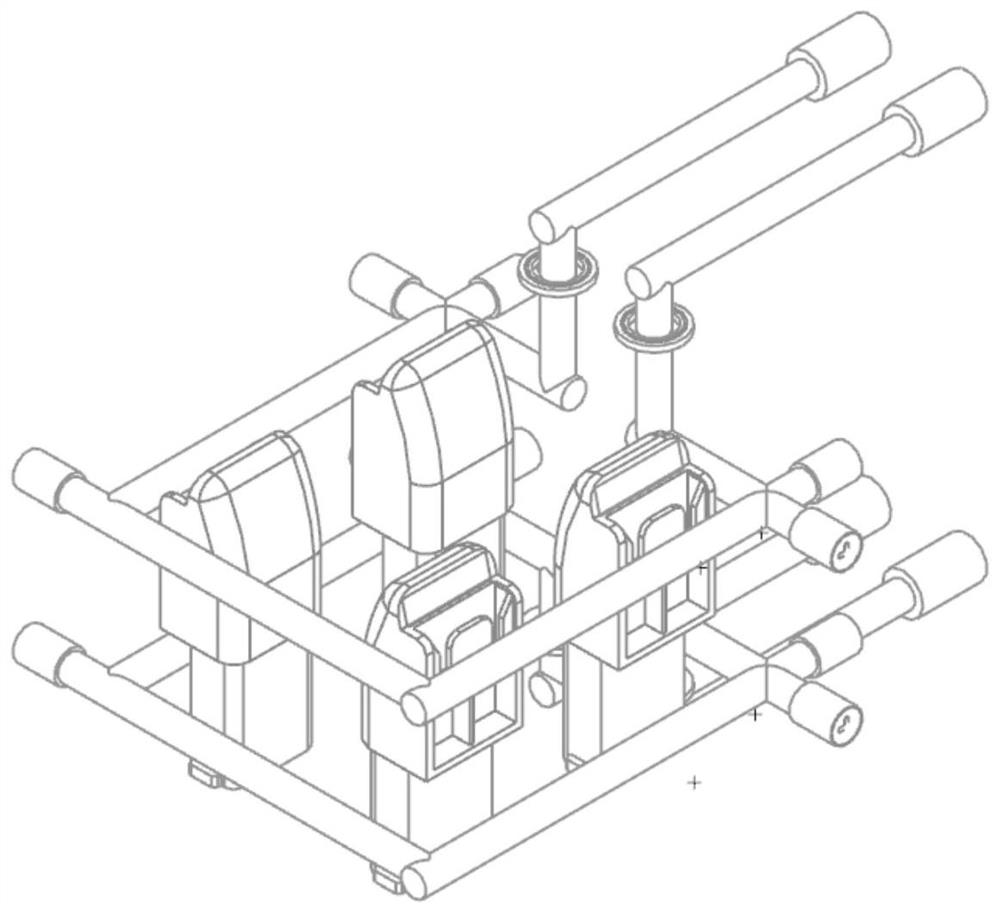

[0023] refer to Figure 1 ~ Figure 4 , an injection mold control plastic part temperature system, including an injection mold part, a temperature measurement control part and a cooling water tank part;

[0024] The injection mold part includes a main body injection mold 7 and a cooling water pipe arranged inside the injection mold;

[0025] The temperature measurement and control part includes a wireless thermocouple 5, a data acquisition module, a controller and a controllable hydraulic pump 8; the wireless thermocouple 5 is installed in the main body injection mold 7 for detecting the injection temperature; The wireless thermocouple 5 is connected with the data acquisition module, the data acquisition module is connected with the controller, and the controller is connected with the controlled end of the controllable hydraulic pump 8;

[0026] The inlet of the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com