Method setting exhausting parameters of vulcanizing machine according to vulcanization curve of rubber compound and used for producing sealing part

A technology of vulcanization curve and compounding rubber is applied in the field of setting the exhaust parameters of the vulcanizer according to the vulcanization curve of the compounded rubber in the production of seals. , the effect of eliminating the problem of air pockets and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A method for setting exhaust parameters of a vulcanizer according to the vulcanization curve of a compound rubber used in the production of seals, comprising the following steps:

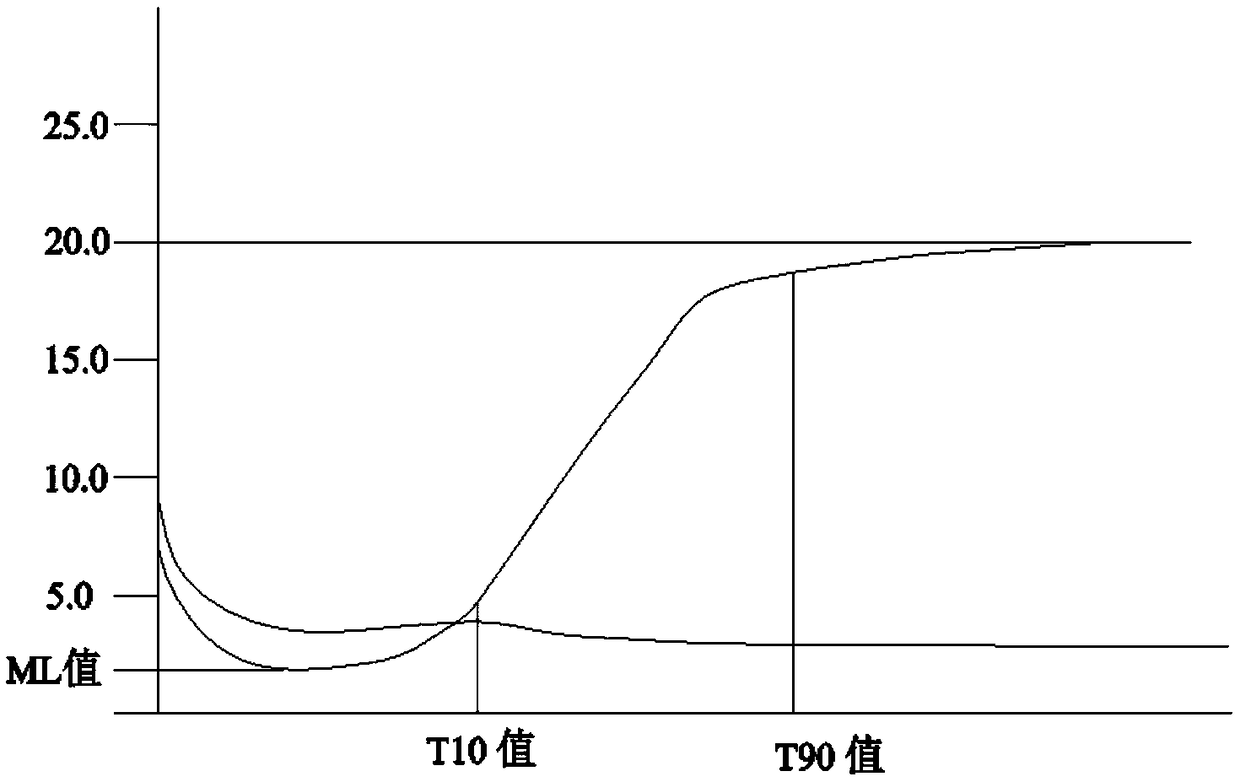

[0020] Refer to the product of 1 / ML and T10 for the setting of exhaust parameters;

[0021] The sum of the times of the exhaust parameters is less than the T10 time;

[0022] Among them, the ML value represents the minimum torque, the unit is dNm, and the T10 value represents the scorch time of the rubber compound, the unit is min;

[0023] As the product of 1 / ML and T10 increases, increasing the exhaust speed means shortening the exhaust time; as the product of 1 / ML and T10 decreases, decreasing the exhaust speed means prolonging the exhaust time.

[0024] The method for setting the exhaust parameters of the vulcanizer according to the vulcanization curve of the compound rubber used in the production of seals according to the present invention greatly reduces the time for experiment debuggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com