Valve plate and hydraulic rotating device

A technology of rotating devices and valve plates, which is applied to components of pumping devices for elastic fluids, liquid fuel engines, machines/engines, etc., and can solve problems such as reduction of opening area, cavitation of valve plates, and negative pressure , to achieve the effect of preventing cavitation, preventing pollution and preventing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

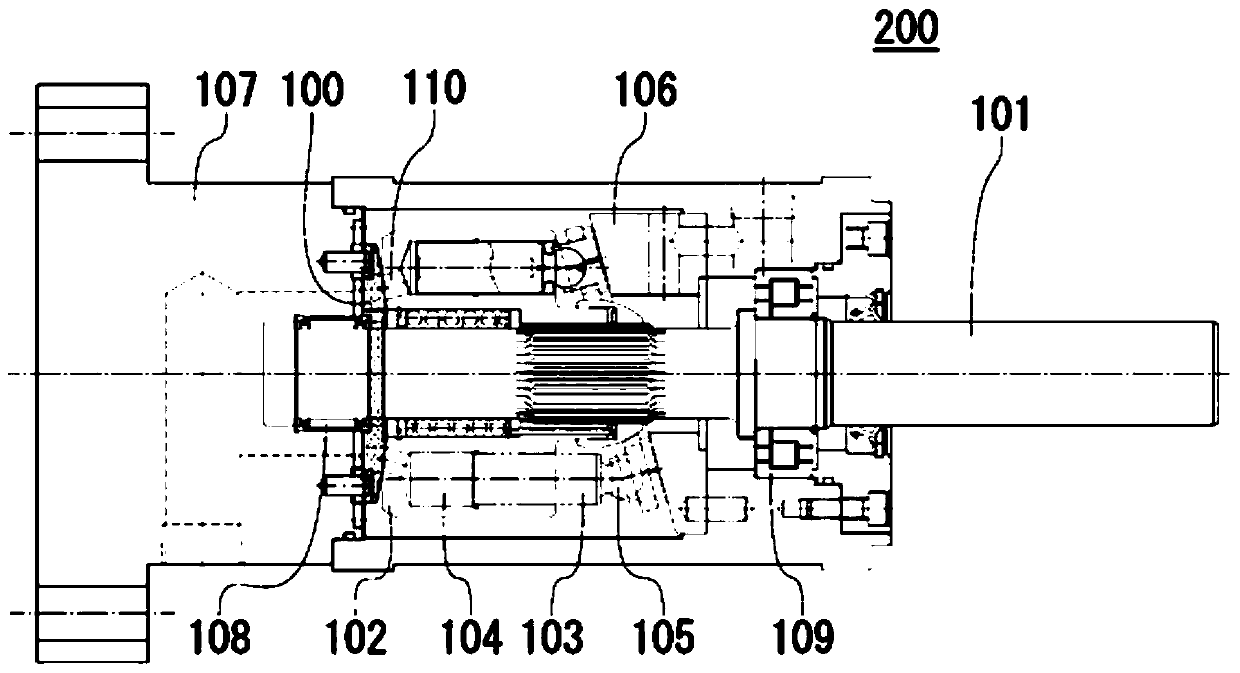

[0069] figure 1 It is a schematic sectional view of the hydraulic rotation device 200 provided with the port plate 100 of 1st Embodiment. The hydraulic rotating device 200 is used for the purpose of pressurizing hydraulic fluid supplied to drivers in industrial machines and construction machines, etc., using an electric motor, an engine, or the like as a power source.

[0070] (Structure of hydraulic turning device 200)

[0071] The hydraulic rotating device 200 includes a rotating shaft 101 , a cylinder 102 , several plungers 103 , several sliding shoes 105 , a swash plate 106 , and a flow plate 100 . The rotary shaft 101 is rotatably supported by bearings 108 and 109 in a housing 107 . Several plunger cavities 104 are formed in the cylinder body 102, and the cylinder body 102 is combined with the rotating shaft 101 and rotates together with the rotating shaft. One end of each plunger chamber 104 is opened at one end of the cylinder 102 , and the other end is opened at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com