A transformer riser lead wire clamping device

A clamping device, lead wire technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problem of poor electrical strength and mechanical strength of laminated wood materials, insufficient insulation distance, and can not meet the noise level of converter transformers It can reduce the partial discharge, improve the heat dissipation effect, and avoid the phenomenon of air pockets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

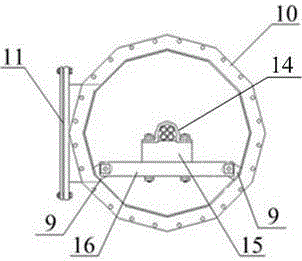

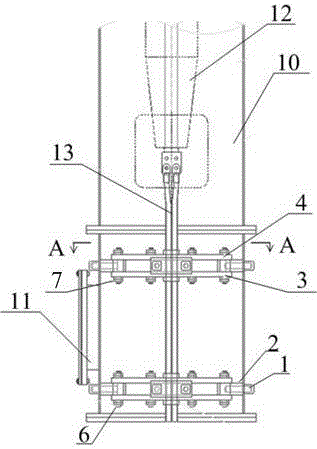

[0018] The drawings show a specific embodiment of the invention. The lead clamping device of the transformer elevated base of the present invention includes a laminated cardboard support frame 2 located inside the elevated base 10, a first laminated cardboard support 3 located below the laminated cardboard support frame 2, and a second laminated cardboard support 4 located above , And the laminated cardboard cover plate 5, there are 4 fixing holes 17 on the wall of the raised base 10, the fixing holes 17 are welded with round head nuts 1, and the laminated cardboard support frame 2 is passed through the screw 6 and the nut 7. The fixing hole 17 and the round head nut 1 are fixed inside the raised seat 10. The first laminated cardboard support 3, the laminated cardboard branch line 2 and the second laminated cardboard support 4 are fixed by the screw 6 and the nut 7. The laminated cardboard cover 5 is located at the center of the elevated base 10 and fixed on the first laminated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com