Denitration device ammonia spraying accurate control system and method based on accurate concentration prediction

A concentration prediction and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve problems such as sulfate air preheater, catalyst blockage, ammonia escape, and the amount of ammonia injection cannot be accurately controlled, etc., to achieve Improve economy and stability, and overcome the effect of large inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

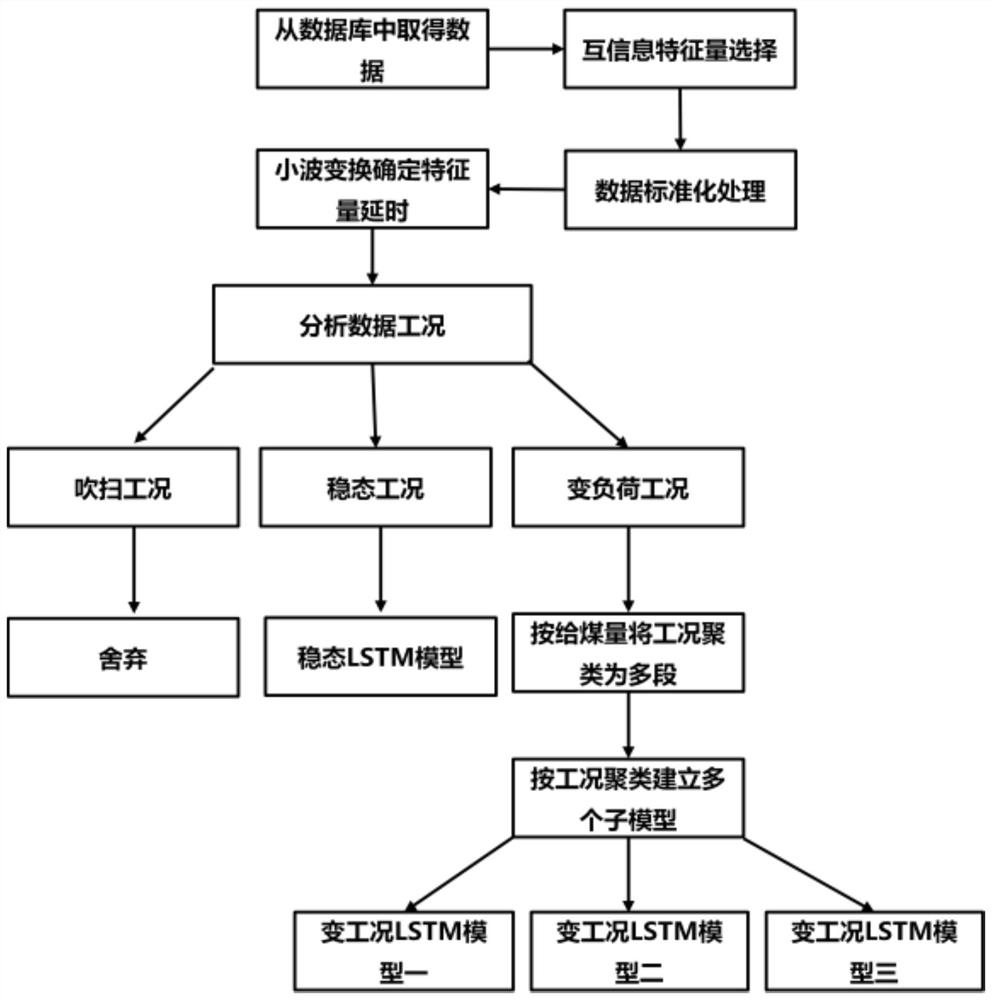

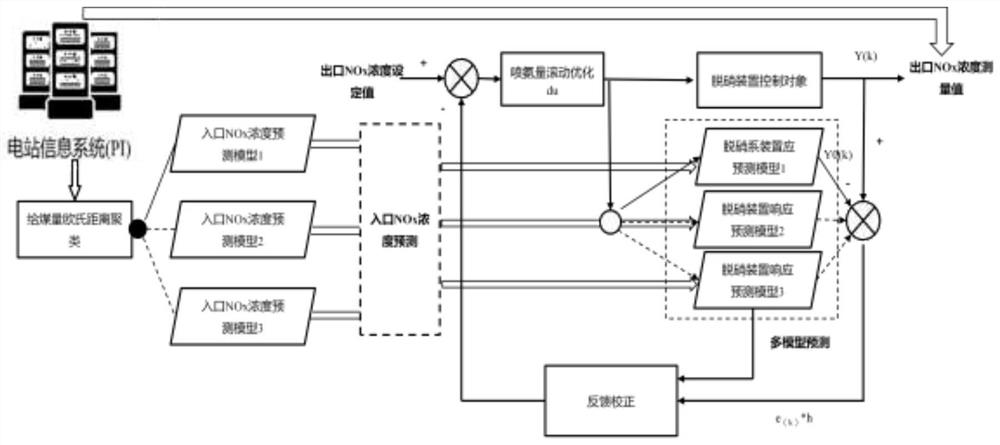

[0058] refer to figure 1 , figure 2 , the present invention aims at the characteristics of the large-scale variable load operation of the CFB boiler unit, and proposes a method based on the inlet NO x The ammonia injection precision control system of the denitrification device with accurate concentration prediction can precisely control the ammonia injection device; the ammonia injection precision control system includes the power station information system, the NOx concentration prediction model at the entrance of the denitration device, the multi-model predictive control module, and the denitrification device control module. object;

[0059] The power station information system includes a power plant OPC server and DCS control equipment. When the present invention controls the unit in real time, the NOx concentration prediction model at the inlet of the denitration device communicates with the OPC server of the power plant, and transmits the DCS data to the NOx concentrati...

Embodiment 2

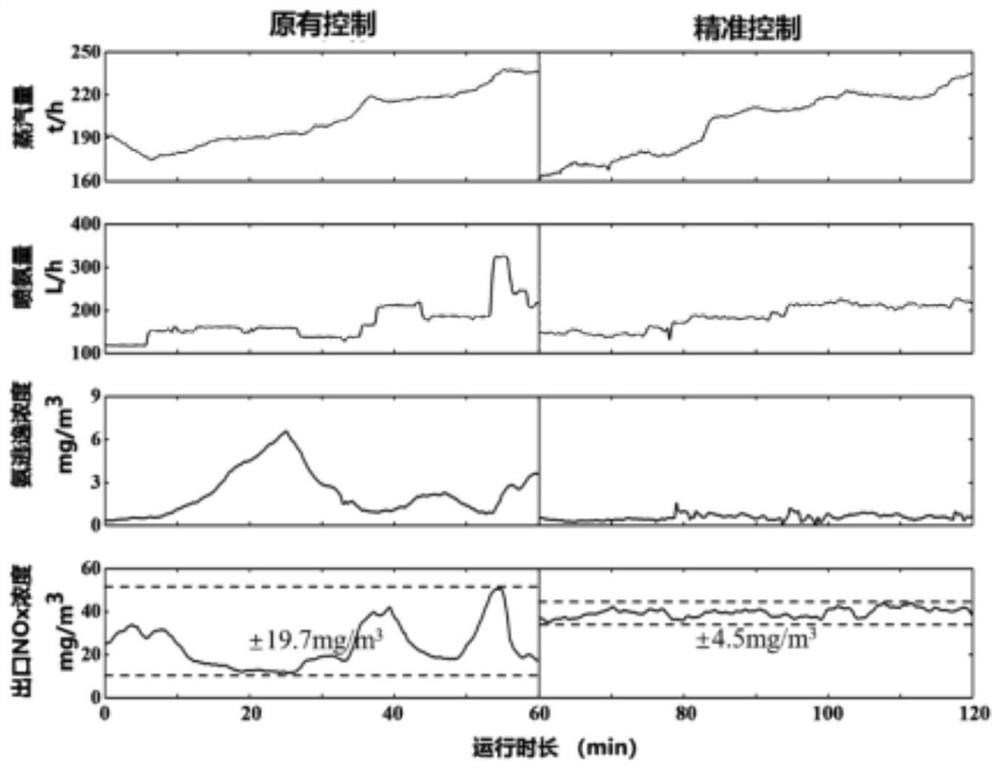

[0105] Taking the actual control process and short-term and long-term control effects of a certain 220t / h circulating fluidized bed pulverized coal furnace as an example, describe the content of the present invention in detail:

[0106] (1) Select 4 coal feed rates, 2 primary air volumes, 2 secondary air volumes, 10 hearth temperatures, 2 furnace outlet flue temperatures, 1 main steam flow rate, and 1 flue gas O 2 A total of 22 input characteristic variables of volume percentage are clustered based on the operating coal supply data of the last two months, and the cluster centers are determined to be 12.1t / h, 18.0t / h, and 26.0t / h; input after data and processing In the LSTM model, the prediction time step is selected as 14, the backtracking time step is 30, 2 hidden layers, and 128 hidden layer nodes in each layer; the LSTM model is established with this hyperparameter configuration to predict the NOx concentration at the inlet of the denitrification device;

[0107] (2) M=1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com