Non-woven composite material with elastic structure and preparation method of non-woven composite material

A composite material and non-woven technology, applied in non-woven fabrics, textiles and papermaking, medical science, etc., can solve the problems of high cost of elastic polymer raw materials, poor air permeability of non-woven fabrics, insufficient structural stability, etc., and achieve excellent softness. The effect of high degree and breathability, fluffy structure and strong elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

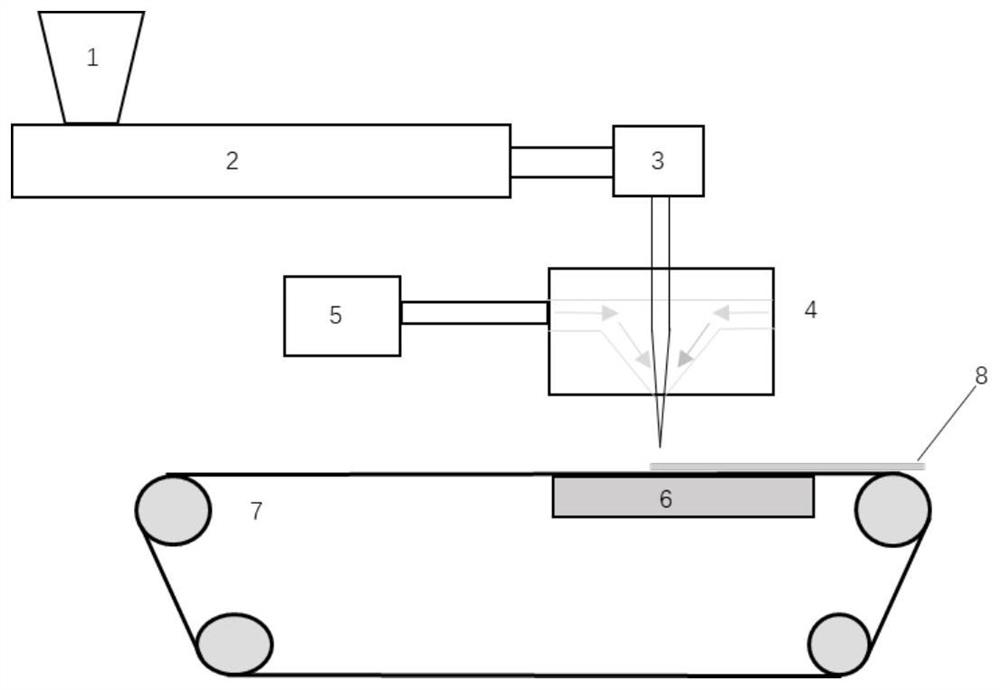

[0040] This embodiment provides a method for preparing a structurally elastic nonwoven composite material, the preparation steps of which are as follows:

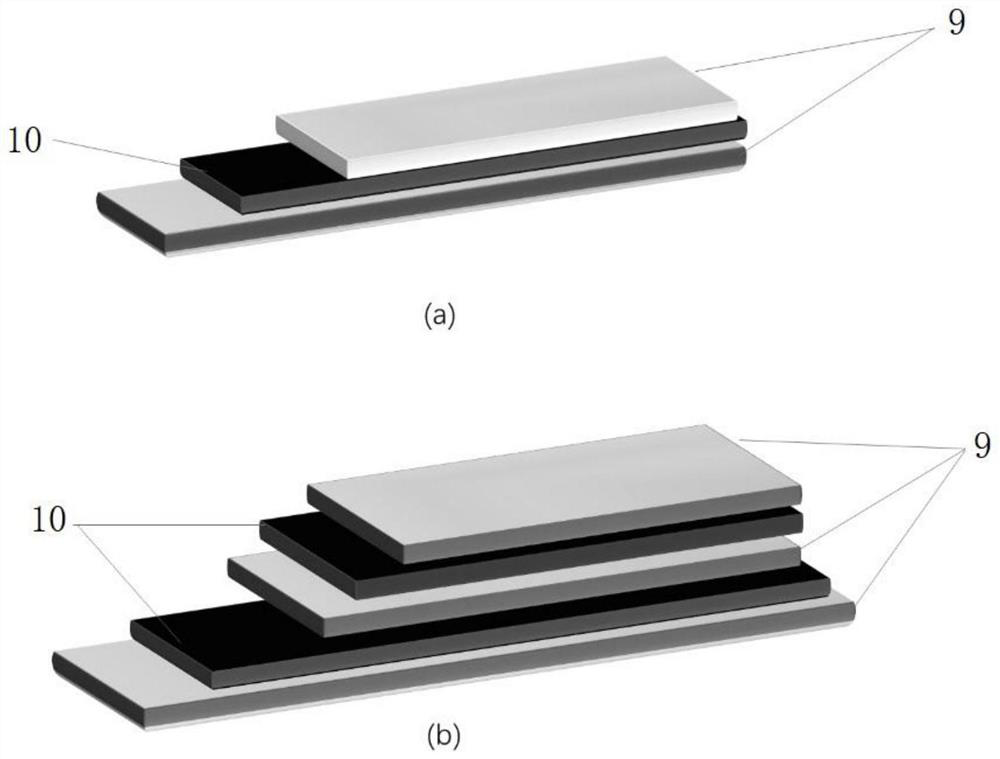

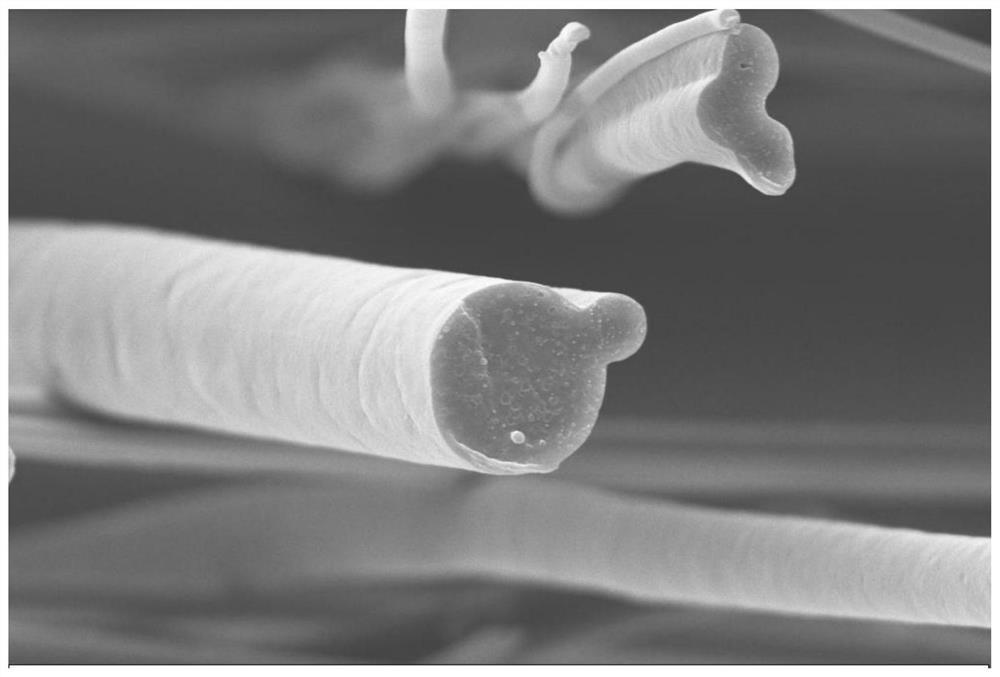

[0041] (1) Preparation of ultrafine elastic fiber layer: the preparation process is as follows figure 1As shown, polyethylene terephthalate-1,4-cyclohexanedimethanol (k2012, SK Global Chemical Co., Ltd.) and polyolefin elastomer (7050FL, ExxonMobil Chemical) were mixed according to the mass ratio The ratio of 5:5 is physically blended and put into the melt blown testing machine. The specific melt blown process parameters are set as follows: metering pump temperature 260°C, melt blown die head temperature 290°C, screw extruder temperature (zone 1 - zone 4 zone): 260°C, 270°C, 280°C, 290°C; metering pump speed 7r / min, fan speed 45r / min, winding speed 1.7r / min, receiving distance 20cm. The obtained blended fiber has an average diameter of 0.8um and a grammage of 40g / m 2 .

[0042] (2) Preparation of the main fiber layer; th...

Embodiment 2

[0047] The preparation method of a structurally elastic non-woven composite material provided in this embodiment is the same as that of the first embodiment, except that the process parameter of the receiving distance of the heat-shrinkable elastic layer is set to 25 cm.

Embodiment 3

[0049] The preparation method of a structurally elastic non-woven composite material provided in this embodiment is the same as that of the first embodiment, except that the process parameter of the receiving distance of the heat-shrinkable elastic layer is set to 30 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com