High-performance dual-phase magnesium-lithium alloy material and preparation method thereof

A magnesium-lithium alloy, high-performance technology, applied in the field of high-performance dual-phase magnesium-lithium alloy materials and preparation, can solve the problems of weak basic research and short start-up time of magnesium-lithium alloys, and achieve the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

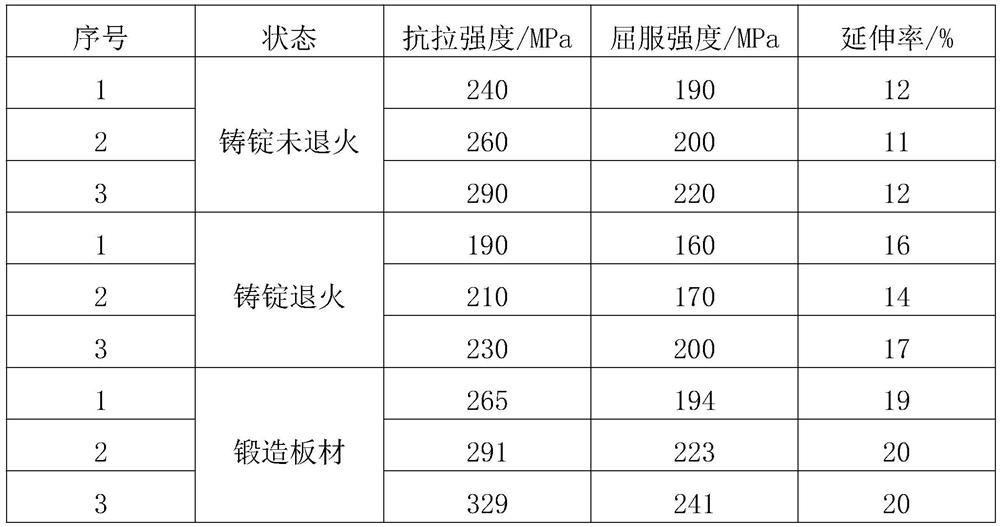

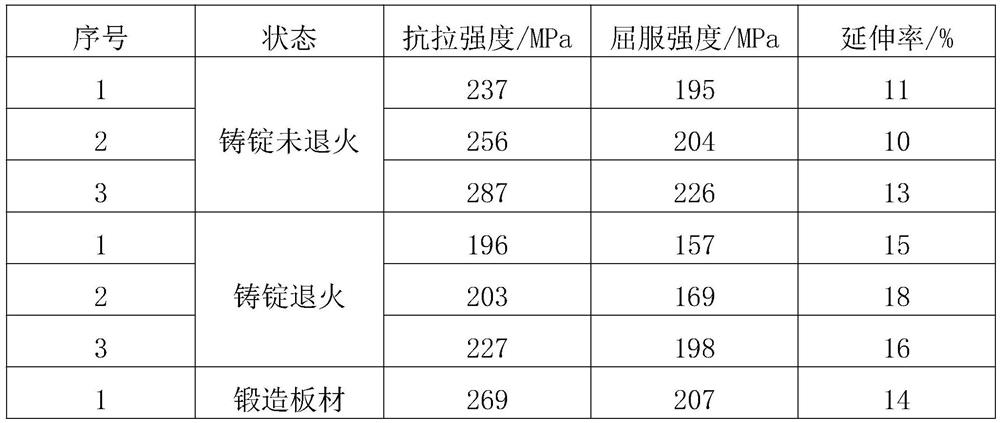

Embodiment 1

[0024] The high-performance dual-phase magnesium-lithium alloy material of the present invention comprises the following composition by mass percentage: magnesium element: balance, lithium element: 6%, Al element: 2.5%, Zn element: 2.5%, Cd element: 0.8%, Zr element: 0.9%.

[0025] Its preparation method is as follows:

[0026] 1) Melting into ingots according to the above mixing ratios, the melting process is as follows: the melting equipment is a vacuum melting furnace, the vacuum degree in the furnace is kept below 60Pa, the heating power is 30kw, and after 20 minutes of preheating, the heating power is 45kw. The solution is completely melted, and then kept at a heating power of 33kw for 40 minutes, then cooled at a heating power of 20kw for 25 minutes to the pouring temperature, and then poured;

[0027] 2) Ingot annealing:

[0028] Perform homogenization annealing on high-performance dual-phase magnesium-lithium alloy ingots, annealing temperature: 280°C, annealing time...

Embodiment 2

[0038] The high-performance dual-phase magnesium-lithium alloy material of the present invention comprises the following composition by mass percentage: magnesium element: balance, lithium element: 8%, Al element: 3.0%, Zn element: 3.0%, Cd element: 1.3%, Zr element: 0.6%.

[0039] Its preparation method is as follows:

[0040] 1) Melt into ingots according to the above mixing ratios. The melting process is as follows: the melting equipment is a vacuum melting furnace, the vacuum in the furnace is kept below 60Pa, the heating power is 20kw, and after 25 minutes of preheating, the heating power is 40kw. The solution is completely melted, and then kept at a heating power of 30kw for 50 minutes, then cooled at a heating power of 25kw for 15 minutes to the pouring temperature, and then poured;

[0041] 2) Ingot annealing:

[0042] Perform homogenization annealing on high-performance dual-phase magnesium-lithium alloy ingots, annealing temperature: 230°C, annealing time: 12 hours...

Embodiment 3

[0052] The high-performance dual-phase magnesium-lithium alloy material of the present invention comprises the following composition by mass percentage: magnesium element: balance, lithium element: 11%, Al element: 3.2%, Zn element: 3.5%, Cd element: 1.8%, Zr element: 1.5%.

[0053] Its preparation method is as follows:

[0054] 1) Melting into ingots according to the above proportions, the melting process is as follows: the melting equipment is a vacuum melting furnace, the vacuum in the furnace is kept below 60Pa, the heating power is 40kw, and after 10 minutes of preheating, the heating power is 50kw and heated to The solution is completely melted, and then kept at a heating power of 35kw for 35 minutes, then cooled at a heating power of 15kw for 30 minutes to the pouring temperature, and then poured;

[0055] 2) Ingot annealing:

[0056] Perform homogenization annealing on high-performance dual-phase magnesium-lithium alloy ingots, annealing temperature: 340°C, annealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com