Preparation method of Al-Mg-Mn alloy wire

An alloy wire and alloy technology, which is applied in the field of preparation of Al-Mg-Mn alloy wire, can solve problems such as Mg segregation, Mg element loss, broken wire, etc., and achieve uniform precipitation, high recrystallization fraction, and improved alloy resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare raw materials according to the alloy composition; the alloy composition contains Mg 6%, Mn 0.8%, Zr 0.1% by mass percentage, the rest is Al and unavoidable impurities; the unavoidable impurities contain Fe≤0.02% by mass percentage, and other impurity elements ≤0.001%; the other impurity elements include Si, Zn, Cu, Ti and Cr;

[0049] Under the condition of argon atmosphere, the raw materials are smelted to obtain an alloy melt; the melting temperature is 740°C;

[0050] Use a metal mold to cast the alloy melt to form an ingot. When the temperature of the ingot drops to 450°C, water quench to room temperature, and then perform homogenization heat treatment at 360°C for 12 hours. After the homogenization heat treatment is completed, water quench to Normal temperature, made into homogenized ingot;

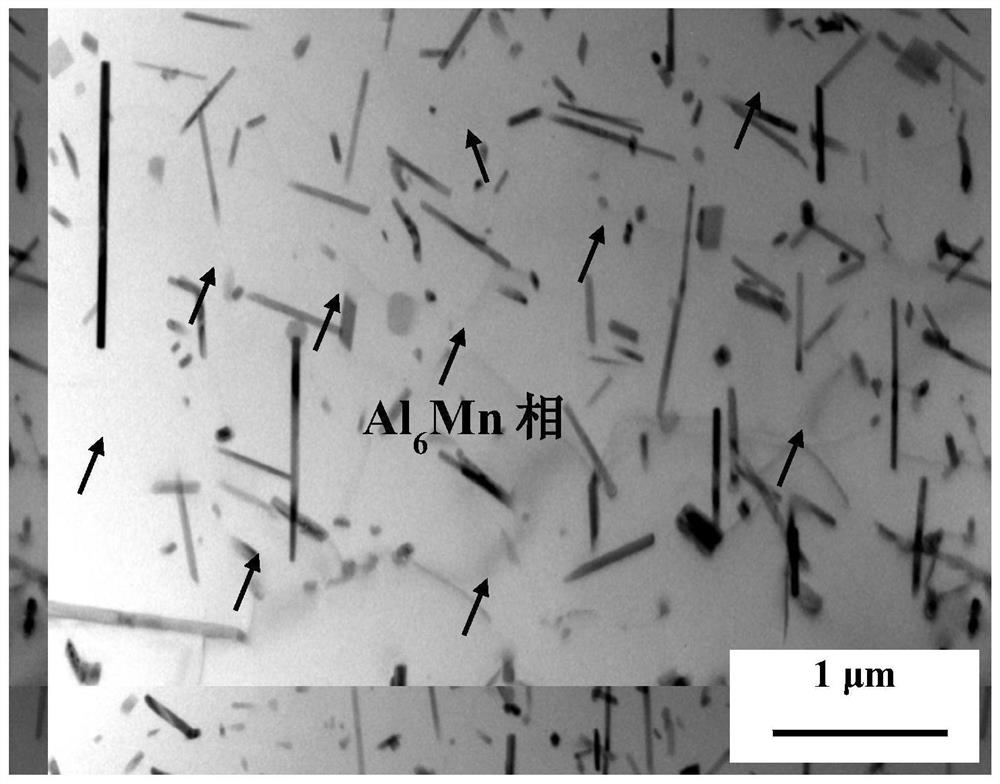

[0051] Heat the homogenized ingot to 500±10°C and keep it warm for 60 minutes; the large-sized Al in the ingot after heat preservation6 The average size of the Mn p...

Embodiment 2

[0057] Method is with embodiment 1, and difference is:

[0058] (1) The alloy composition contains Mg 6.5%, Mn 0.4%, Zr 0.2% by mass percentage;

[0059] (2) The melting temperature is 735°C;

[0060] (3) When the ingot temperature drops to 460°C, water quench to normal temperature;

[0061] (4) Homogenization heat treatment temperature 350°C, time 16h;

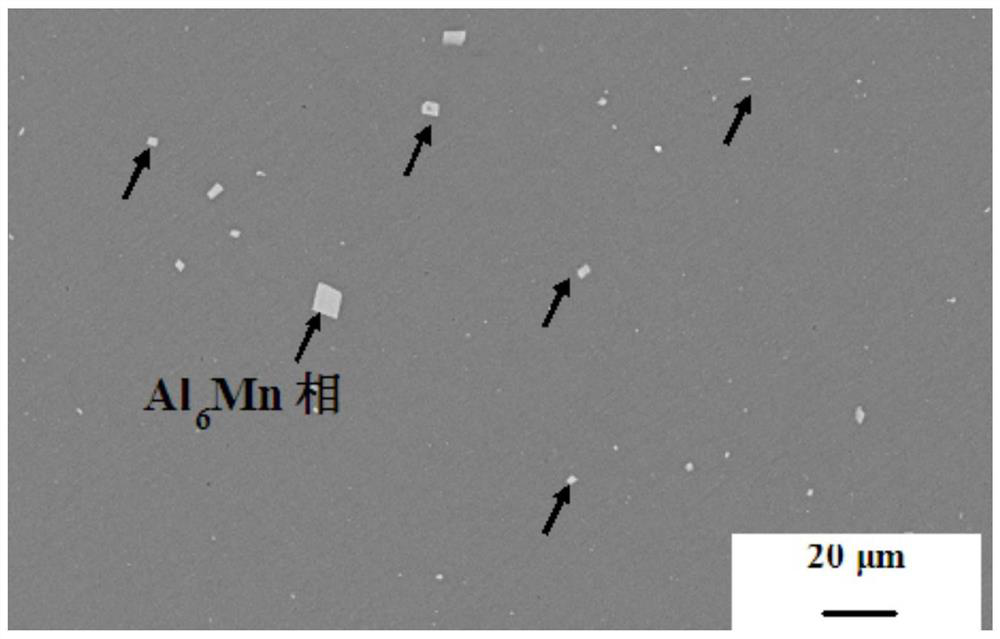

[0062] (5) After 500±10°C, heat preservation for 90 minutes; extrusion ratio 64; small and medium-sized Al extrusion rods 6 The Mn phase is spherical with a diameter of 100-150nm;

[0063] (6) A total of 6 times of drawing were carried out, with a total reduction of area of 84%; the temperature of each intermediate annealing was 450 ° C, the time was 10 min, and the diameter of the Al-Mg-Mn alloy wire was 2 mm;

[0064] (7) The tensile strength of the Al-Mg-Mn alloy wire is 430.54MPa, and the elongation is 13.4%;

[0065] (8) Perform final annealing to adjust the performance of the prepared Al-Mg-Mn alloy wire. The fin...

Embodiment 3

[0067] Method is with embodiment 1, and difference is:

[0068] (1) The alloy composition contains Mg 4.5%, Mn 1.5%, Zr 0.05% by mass percentage;

[0069] (2) The melting temperature is 720°C;

[0070] (3) When the ingot temperature drops to 470°C, water quench to normal temperature;

[0071] (4) Homogenization heat treatment temperature 370°C, time 15h;

[0072] (5) After 500±10°C, keep warm for 120 minutes; extrusion ratio is 36;

[0073] (6) A total of 10 times of drawing were carried out, with a total reduction of area of 96%; the temperature of each intermediate annealing was 400 ° C, the time was 20 minutes, and the diameter of the Al-Mg-Mn alloy wire was 2 mm;

[0074] (7) The tensile strength of the Al-Mg-Mn alloy wire is 470.1MPa, and the elongation is 15.5%;

[0075] (8) Perform final annealing to adjust the properties of the prepared Al-Mg-Mn alloy wire. The final annealing temperature is 400 ° C and the time is 20 minutes to obtain annealed Al-Mg-Mn alloy wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com