Oil displacement surfactant system as well as preparation method and application thereof

A surfactant and oil displacement technology, which is applied in the field of oil displacement surfactant system and its preparation, can solve the problem of oil displacement performance of rare alkyl glycoside surfactant micellar system, high cost of surfactant, uneconomical, etc. problems, to achieve excellent stability, promote displacement and dissolution, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

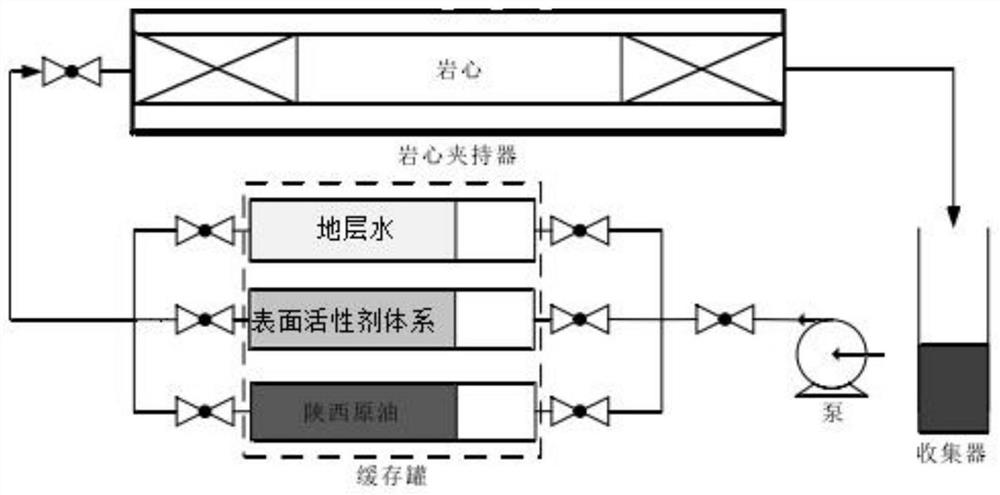

[0037] The invention provides a kind of preparation method of oil displacement surfactant system, comprises the steps:

[0038] P1, add surfactant, esterification aid, and inorganic salt into 100g of water according to the mass ratio of (0.2~2)g:(0.1~1)g:(0.05~0.5)g to obtain a mixed solution, and conduct ultrasonic Treat for 20-30 minutes;

[0039] P2, the ultrasonically treated mixed solution is subjected to high-speed shearing treatment at 30-50° C. for 6-10 hours to prepare a micellar oil displacement surfactant system.

[0040] Preferably, the high-speed shearing speed is 300-600 r / min.

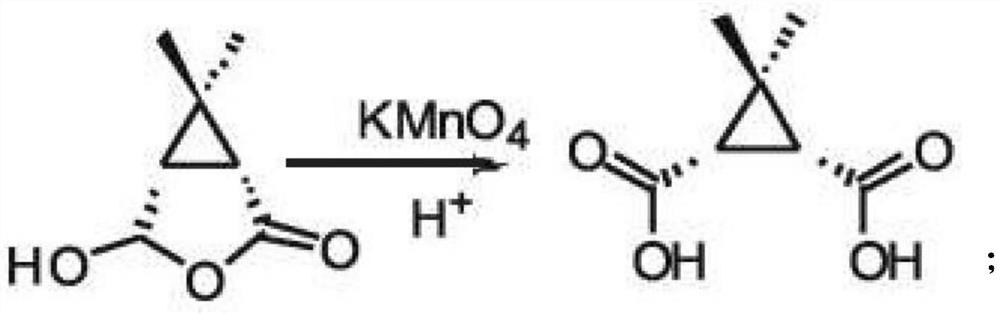

[0041] Preferably, the synthesis route of the esterification auxiliary agent is as follows:

[0042] S1, using chiral carvalolactone as raw material, adjusting the pH value to acidity, and then in KMnO 4 Ring opening under action gives chiral cyclopropanedicarboxylic acid:

[0043]

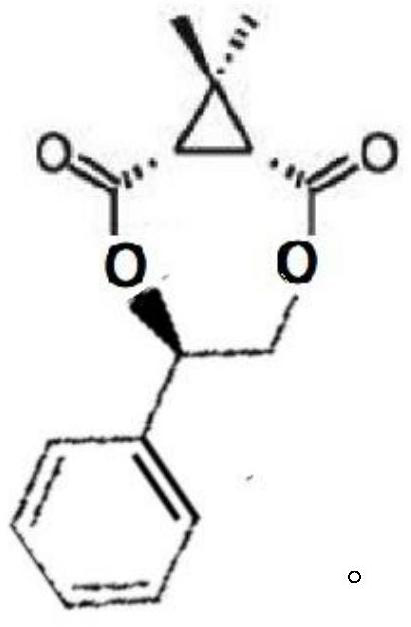

[0044] S2, the esterification reaction of chiral cyclopropanedicarboxylic acid and chiral phenyl g...

Embodiment 1

[0049] Embodiment 1 of the present invention provides an oil displacement surfactant system, which is a micellar composite flooding system with a particle size of less than 50 nm composed of alkyl glycoside surfactants, esterification aids, inorganic salt sodium chloride and water. Oil agent;

[0050] Wherein, the preparation process of esterification auxiliary agent is as follows:

[0051] S1, under the condition of constant mechanical stirring, add 24g of carvalolactone and 300g of water into the beaker, then adjust the pH value of the solution to 2 with concentrated sulfuric acid; then add the total amount of 37.5g in three times at 0°C KMnO 4 , naturally warming to room temperature, continue to stir the reaction for 12h, filter, and the filtrate is washed with 10% K 2 CO 3 Adjust the pH value to 8-9, wash the water phase with 100mL diethyl ether, adjust the pH value of the water phase to 2-3 with concentrated sulfuric acid, extract with anhydrous diethyl ether, wash wit...

Embodiment 2-6

[0064] The difference from Example 1 is that the ratio of raw materials in the oil displacement surfactant micelle system is set differently, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com