LED (light-emitting diode) light-curable ink

A technology of light-curing ink and photo-initiator, applied in the field of ink, can solve the problems such as the decrease of curing efficiency of LED light-curing ink, and achieve the effects of improving light-curing efficiency, weakening the influence of oxygen inhibition and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

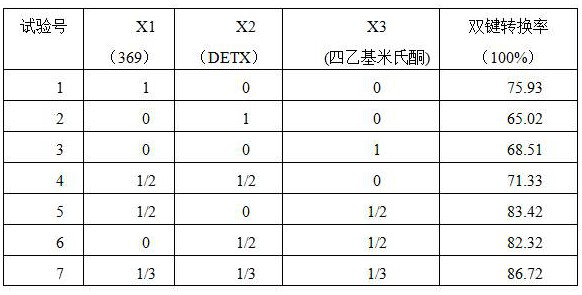

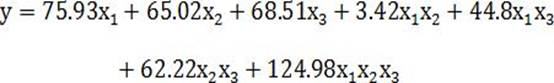

Examples

Embodiment 1

[0030] In this embodiment, the LED photocurable ink includes components: 50 parts of prepolymer, 10 parts of monomer, 2.2 parts of auxiliary agent, 5.5 parts of photoinitiator and 16 parts of pigment.

[0031] Among them, 50 parts of prepolymers include 45 parts of modified soybean oil-based rosin polyester and 5 parts of hexafunctional urethane acrylic acid; modified soybean oil-based rosin polyester is obtained by introducing rosin with honeycomb structure and adding epoxy large Soybean oil has the ability to wet and disperse organic pigments, so that the gloss and transfer performance of the ink are significantly improved, and the soybean oil-based rosin polyester has a large molecular weight, a high softening point, and a tighter resin structure, which in turn makes the ink water-resistant. Significantly improved anti-fogging, abrasion and solvent resistance.

[0032] During photocuring, the initiator causes the carbon-carbon double bond of the urethane acrylate to react w...

Embodiment 2

[0040] In this embodiment, the LED photocurable ink includes components: 60 parts of prepolymer, 5 parts of monomer, 3 parts of auxiliary agent, 5 parts of photoinitiator and 21 parts of pigment.

[0041] Wherein, the prepolymer includes 50 parts of rosin polyester and 10 parts of hexafunctional urethane acrylic acid.

[0042] In this embodiment, the monomer is 5 parts of ditrimethylolpropane acrylate.

[0043] In this embodiment, the additives include 1 part of fatty acid modifier, 0.1 part of N-nitroso-N-phenylhydroxylamine aluminum, 1 part of nano-calcium carbonate and 0.9 part of silicone oil.

[0044] In this embodiment, the photoinitiator includes 1.5 parts of 369, 1.5 parts of DETX and 2 parts of tetraethyl Michler's ketone.

Embodiment 3

[0046] In this embodiment, the LED photocurable ink includes components: 70 parts of prepolymer, 10 parts of monomer, 3 parts of auxiliary agent, 6.5 parts of photoinitiator and 22 parts of pigment.

[0047] In this embodiment, the prepolymer includes 55 parts of rosin polyester and 15 parts of hexafunctional urethane acrylic.

[0048] In this embodiment, the monomer is 10 parts of ditrimethylolpropane acrylate.

[0049] In this embodiment, the additives include 1 part of fatty acid modifier, 0.5 part of N-nitroso-N-phenylhydroxylamine aluminum, 1 part of nano-calcium carbonate and 0.5 part of silicone oil.

[0050] In this embodiment, the photoinitiator includes 2 parts of 369, 2 parts of DETX and 2.5 parts of tetraethyl Michler's ketone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com