Continuous preparation method of 2-aminomalonamide

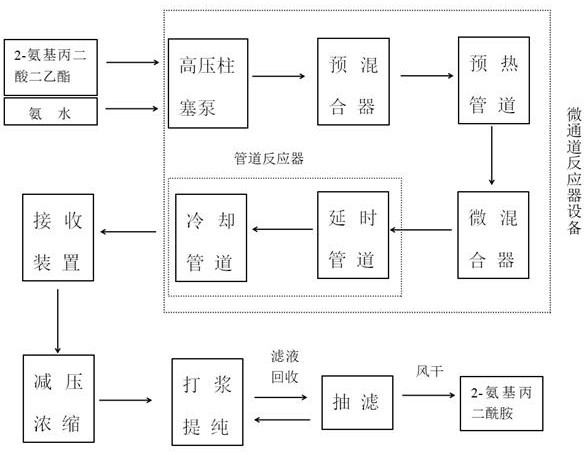

A technology of aminomalonamide and diethyl aminomalonate is applied in the field of continuous preparation of 2-aminomalonamide to achieve the effects of improving reaction efficiency, simple amplification and speeding up reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix diethyl 2-aminomalonate and methanol at a volume ratio of 1:4, then use a high-pressure plunger pump to pump the mixed solution and 25% ammonia water into the pre-mixer at a flow rate ratio of 1:2, and preheat The pipeline is preheated to 45°C, and then enters the microreactor for reaction. The reaction pressure is 2.5Mpa, the reaction temperature is 45°C, and the residence time of the reaction liquid is 11 minutes to obtain a mixed liquid containing 2-aminomalonamide. The mixed liquid is concentrated under reduced pressure to obtain The crude 2-aminomalonamide was purified by beating with methanol, filtered with suction, and the filter cake was air-dried at room temperature to obtain a white or light yellow powdery solid; the yield was 89%. The filtrate evaporates methanol and can be used repeatedly.

Embodiment 2

[0027] This example is the same as Example 1, and the difference with Example 1 is that the reaction temperature in this example is 65°C. The yield thereof was 88.9%.

Embodiment 3

[0029] This example is the same as Example 1, and the difference with Example 1 is that in this example, the reaction temperature is 85° C., and the yield is 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com